Oscillating disc sliding valve pintle axial plunger pump (motor)

An axial piston pump and distribution shaft technology, applied in piston pumps, pumps, multi-cylinder pumps, etc., can solve the problems of poor low-speed performance of oil motors, difficult design of large-displacement piston pumps, and strain of polluted particles. Achieve the effect of increasing the speed, improving the service life, and eliminating the strain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

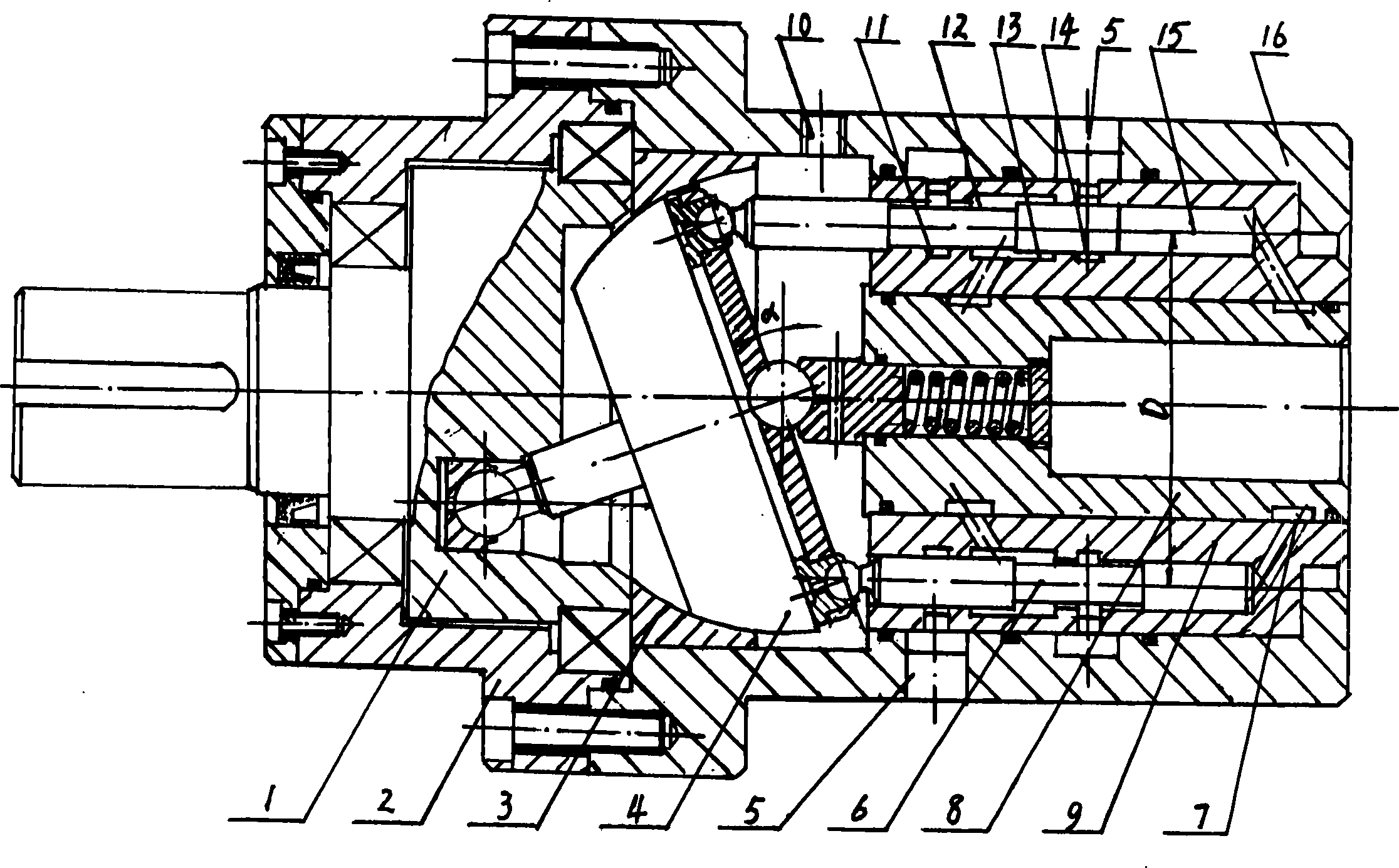

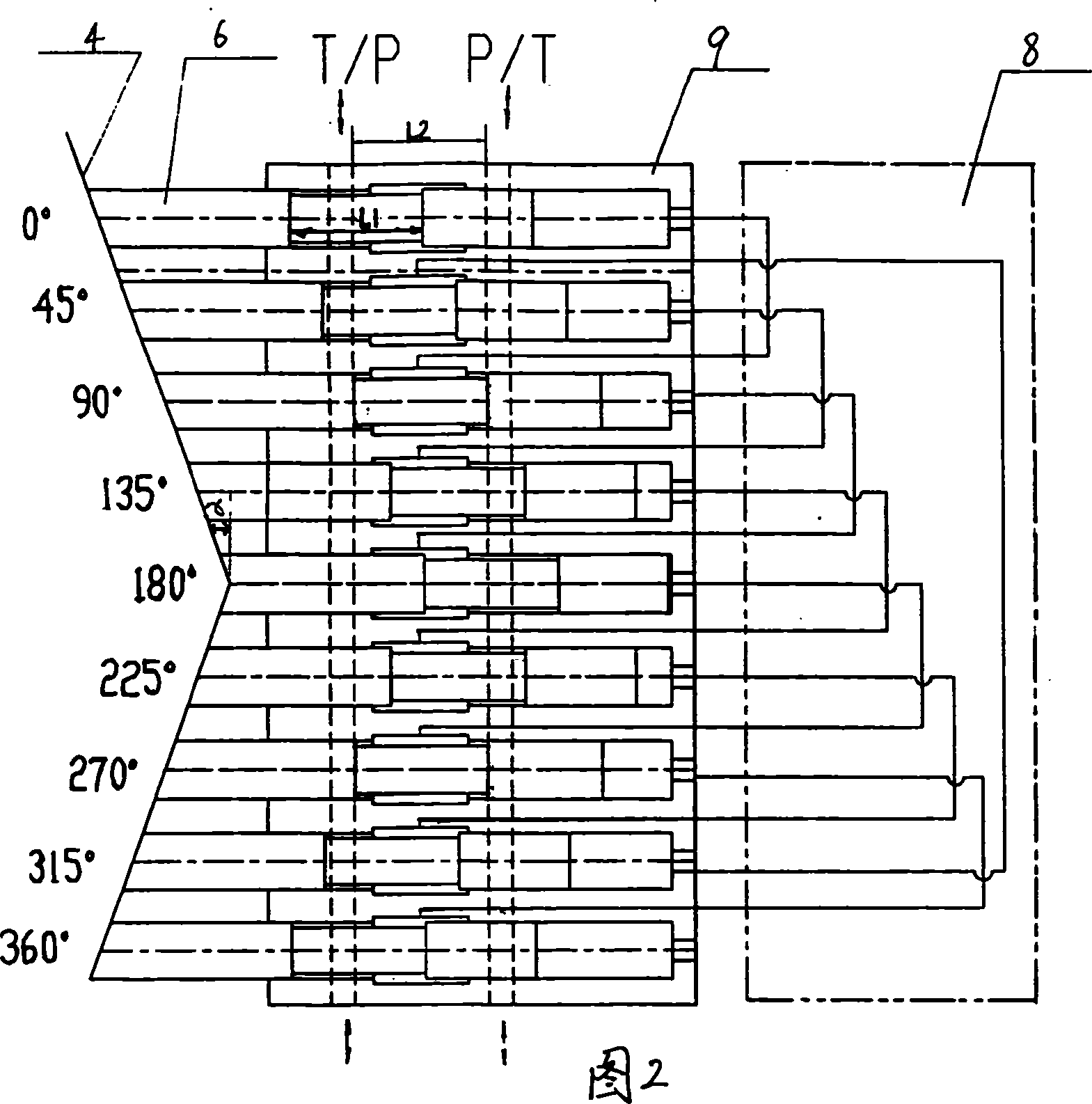

[0013] see figure 1 ,figure 2.

[0014] Swing plate slide valve flow distribution axial plunger pump, including front cover 2, housing 16, drive shaft 1, swing plate 4, plunger 6, flow distribution shaft 8, housing 16 is equipped with cylinder 9, cylinder 9 is installed with a distribution shaft 8, and the transmission shaft 1 rotates in the front cover 2. The transmission shaft 1 is movably connected with the swing plate 4 through a ball joint. The left end of the housing 16 is equipped with a swing seat 3. There is a spherical fit between them, and there is an oil drain port 10 on the housing 16. When the transmission shaft 1 rotates, the oscillating disc 4 swings in the oscillating seat 3, and the oscillating disc 4 and the plunger 6 are also flexibly connected by a ball hinge. 6 is located in the plunger hole 15 in the cylinder body 9. There is one undercut groove 12 on the plunger 6, and there are three left, middle and right undercut grooves 11, 13, 14 on the ring wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com