Dust detection device and electric dust collector mounted with the same

A dust detection and dust technology, applied in vacuum cleaners, cleaning equipment, household appliances, etc., can solve problems such as dust size difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 of the present invention will be described below with reference to the accompanying drawings. Here, the same constituent elements as those in the above existing unit are assigned the same symbols, and their detailed descriptions are omitted.

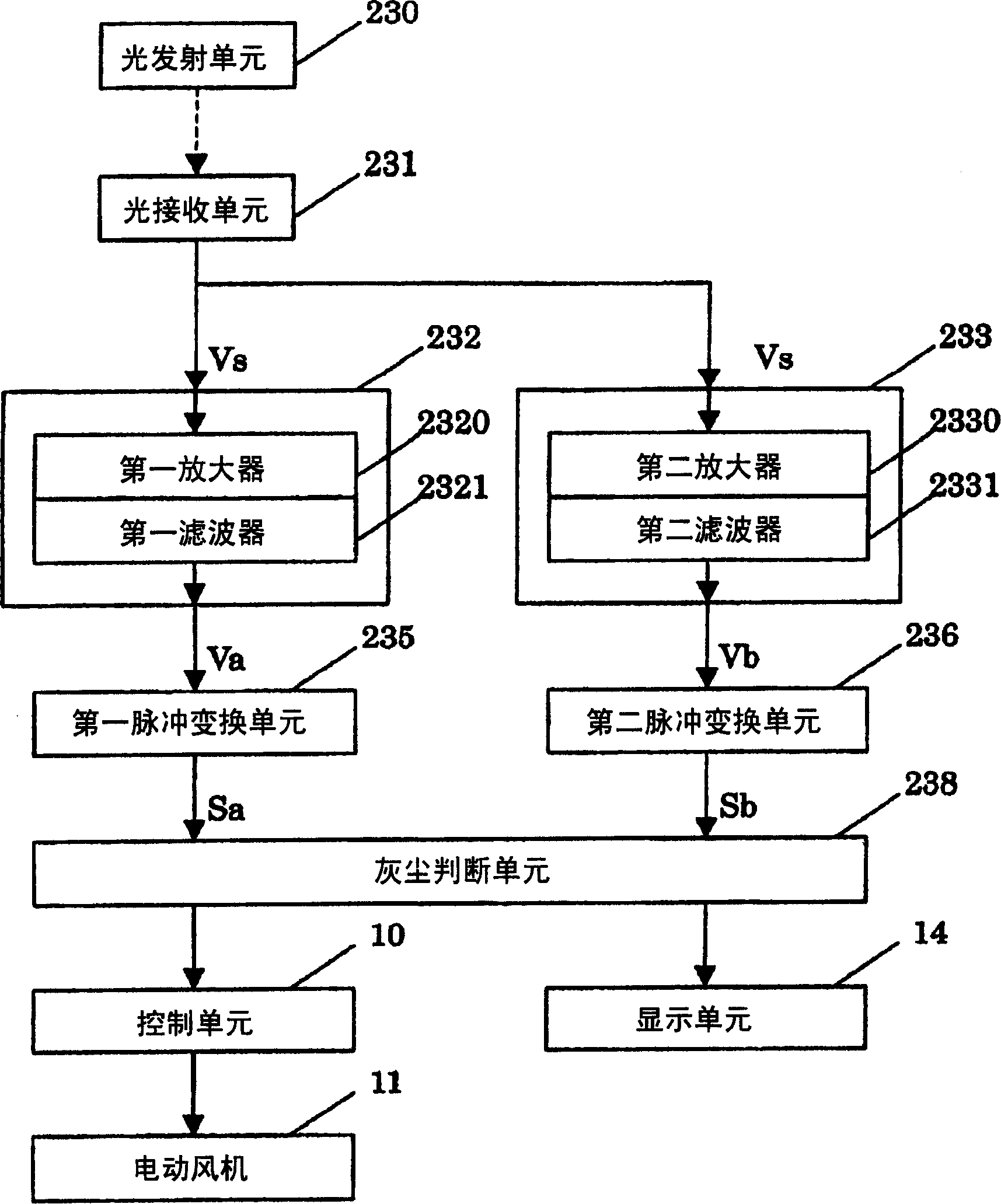

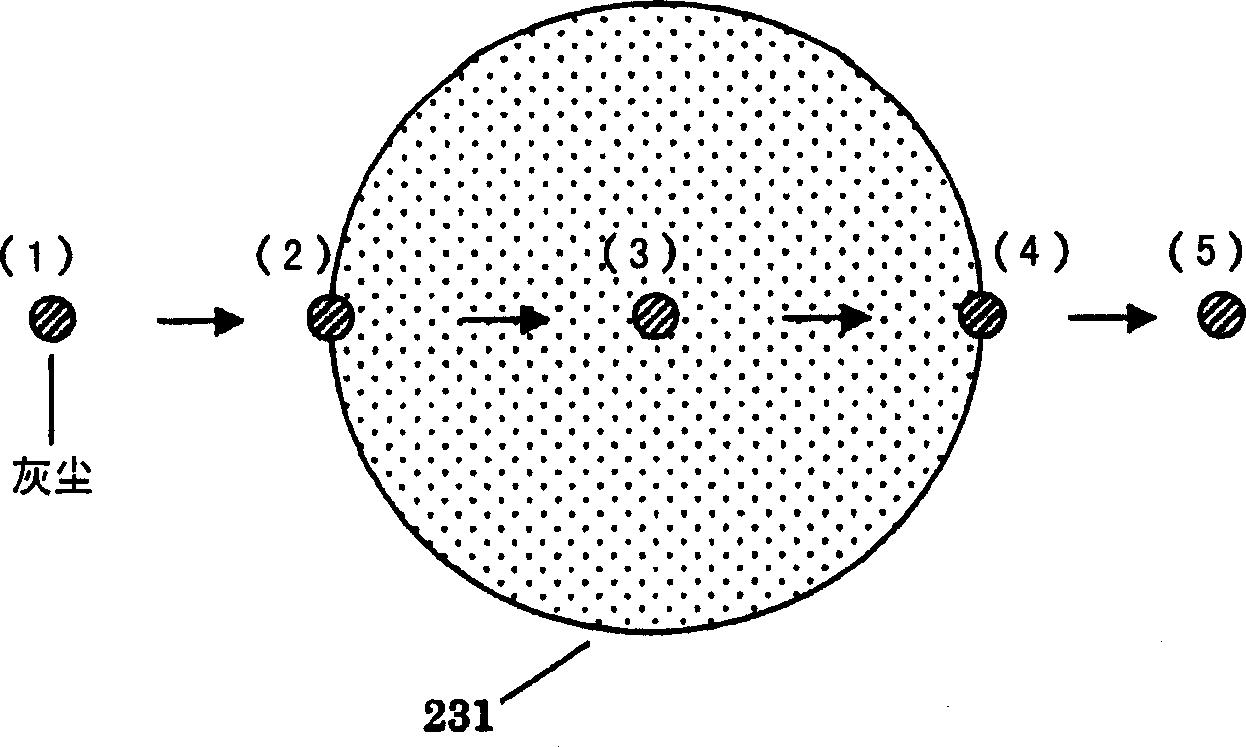

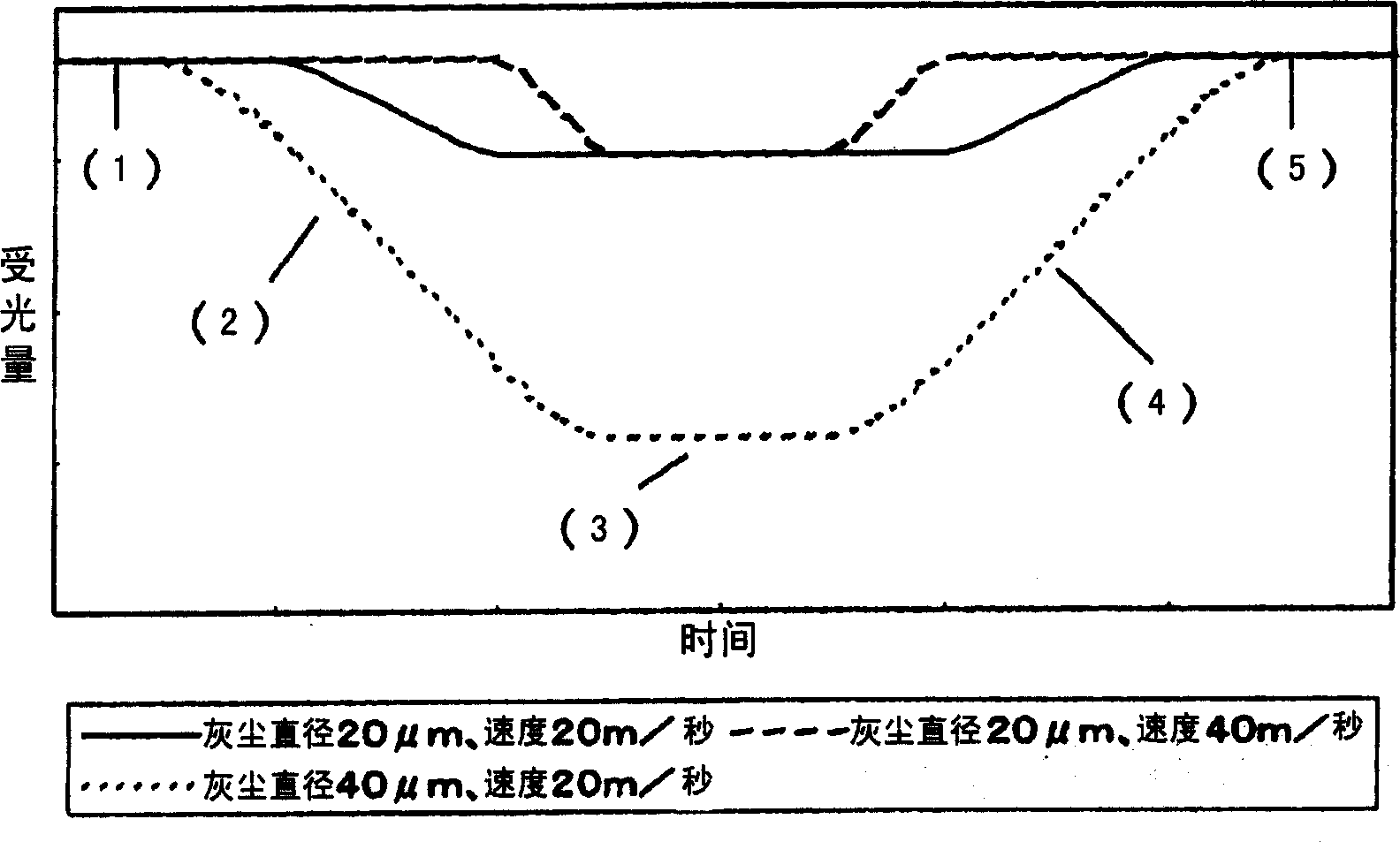

[0027] figure 1 It is a block diagram of the dust detection device in the electric vacuum cleaner according to Embodiment 1 of the present invention. exist figure 1 Among them, 230 and 231 are the light-emitting unit and the light-receiving unit that play the role of dust detection components, the light-emitting unit 230 is used to emit light into the air channel through which the dust flows, and the light-receiving unit 231 is used to receive light from the light-emitting unit 230 output light, and output a signal corresponding to the amount of light received. The light emitting unit 230 and the light receiving unit 231 are disposed opposite to each other in the air passage through which the dust flows. The sig...

Embodiment 2

[0039] Embodiment 2 of the present invention will be described below with reference to the accompanying drawings. In addition, for the same components as those of the conventional unit and the above Embodiment 1, only the same symbols are attached here, and the repeated description thereof is omitted.

[0040] Figure 5 It is a block diagram of an electric vacuum cleaner dust detection device in Embodiment 2 of the present invention. The difference from Embodiment 1 is that the setting of the second amplifying unit 233 is different, the output signal Va of the first amplifying unit 232 is input into the second amplifying unit 233, thereby performing secondary enlarge.

[0041] With such a configuration, since the input impedance of the amplifying unit to the output signal of the light receiving unit 231 can be increased compared with the first embodiment, the stability of the light receiving unit can be improved. In addition, the magnification factor when the second amplify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com