Element absorption method and device

An adsorption device and adsorption position technology, which is applied to electrical components, electrical components, conveyor objects, etc., to achieve the effects of shortening the adsorption cycle, accurate correction, and reducing the number of recognitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be specifically described based on illustrated examples.

[0022] (Example)

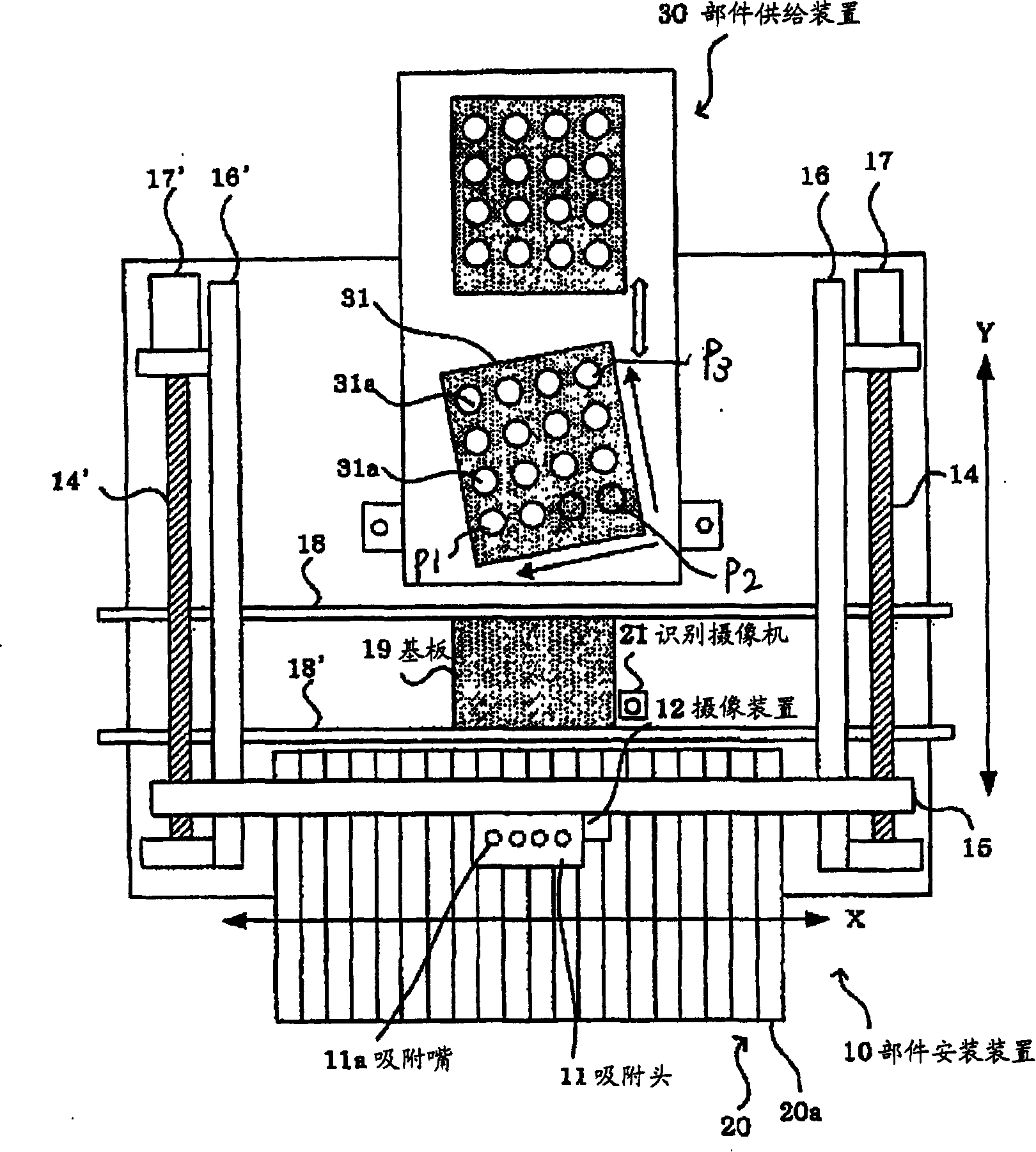

[0023] exist figure 1 The component mounting device 10 is shown in , and the suction head 11 is provided in the component mounting device 10 , which can move in the X-axis direction along the X-axis guide rail 15 by an X-axis motor (not shown). The X-axis guide rail 15 is combined with the screw shaft 14, 14', and the screw shaft is rotated by the Y-axis motor 17, 17', thereby moving in the Y-axis direction along the Y-axis guide rail 16, 16'.

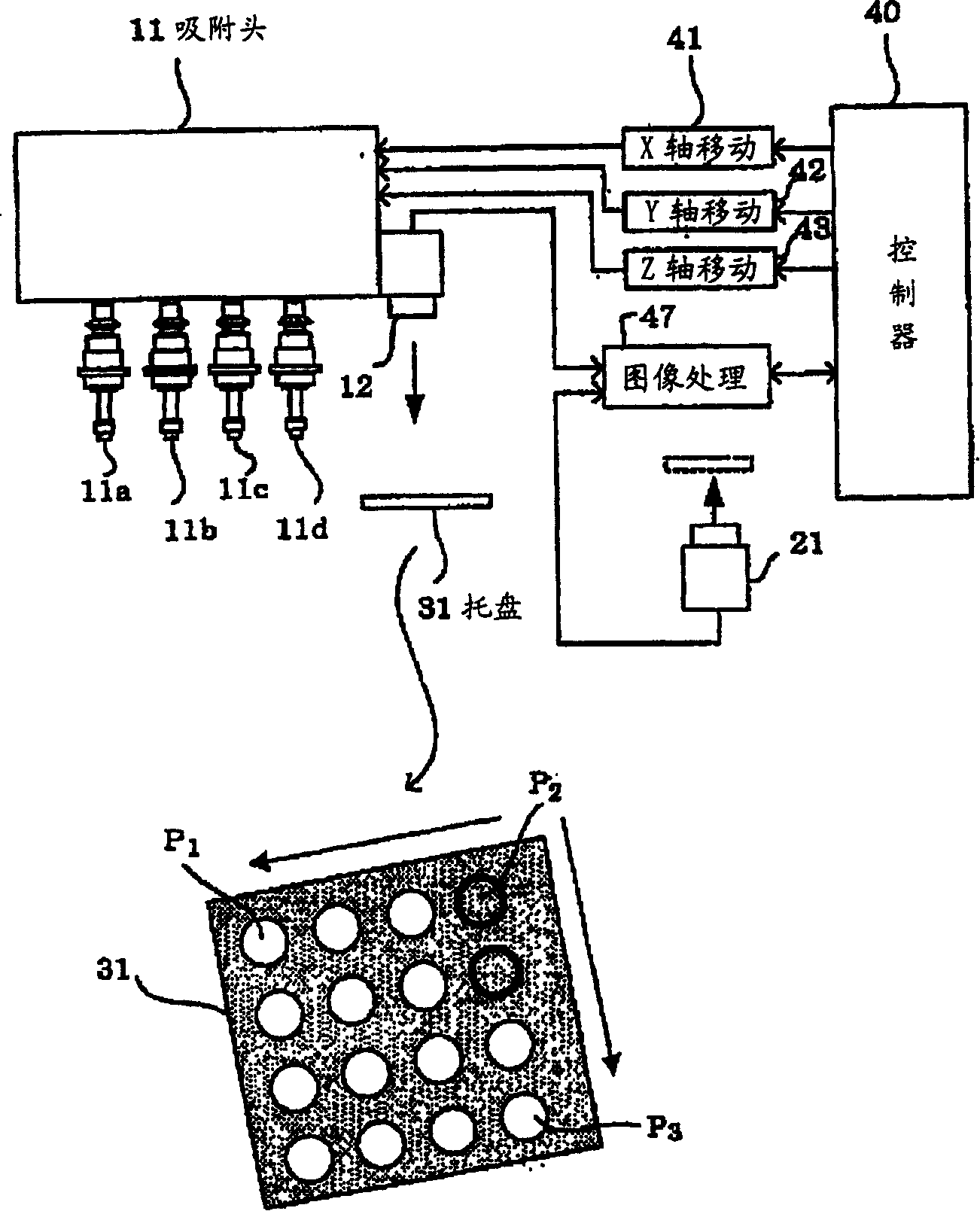

[0024] exist figure 2 Among them, the X-axis moving means such as the X-axis motor and the X-axis guide rail 15 are represented by the reference numeral 41, and the Y-axis movement means such as the Y-axis motor 17, 17', the screw shaft 14, 14', the Y-axis guide rail 16, 16', etc. are represented by the reference numeral 42. Axis movement means. The controller 40 of the component mounting apparatus moves th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com