Labeling apparatus

A labeling and labeling technology, which is applied in the direction of labels, labeling machines, laminating devices, etc., can solve problems such as the inability to adjust the advance travel of the bearing width, and achieve the effect of improving reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

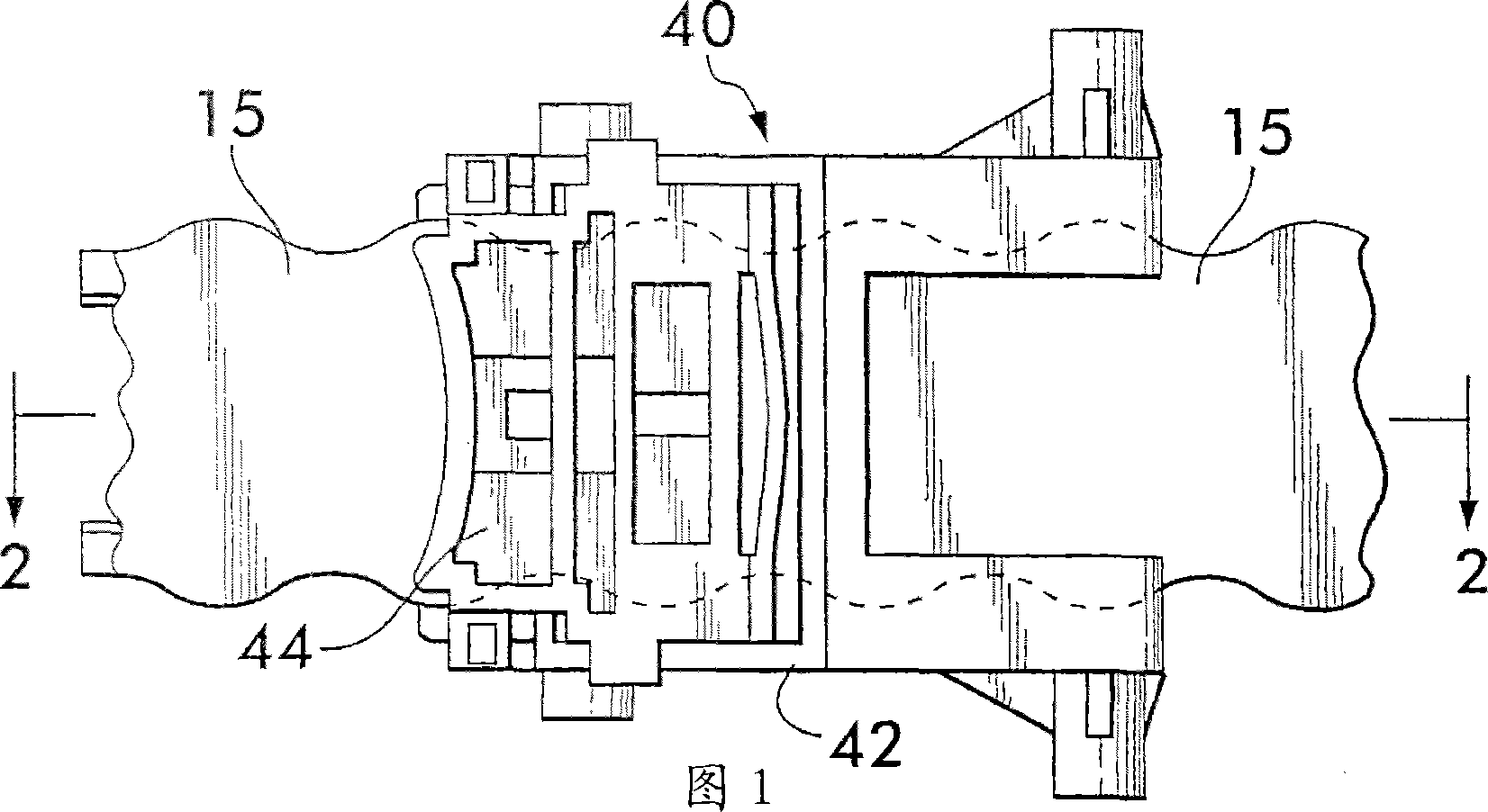

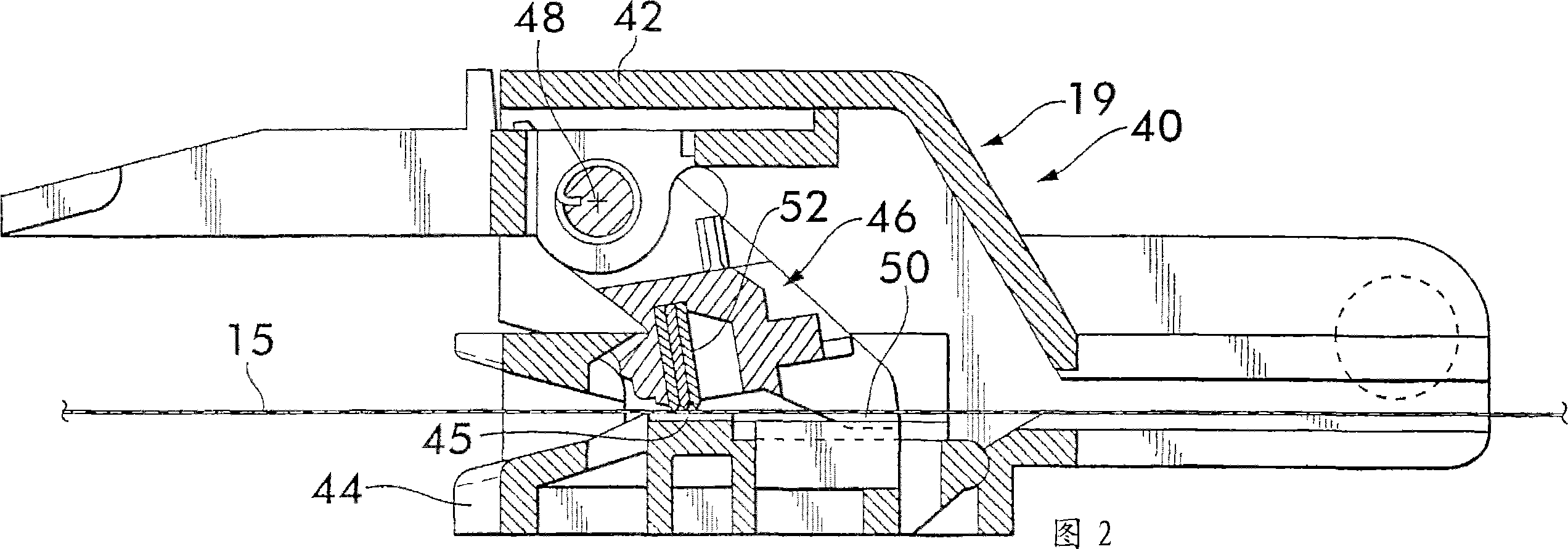

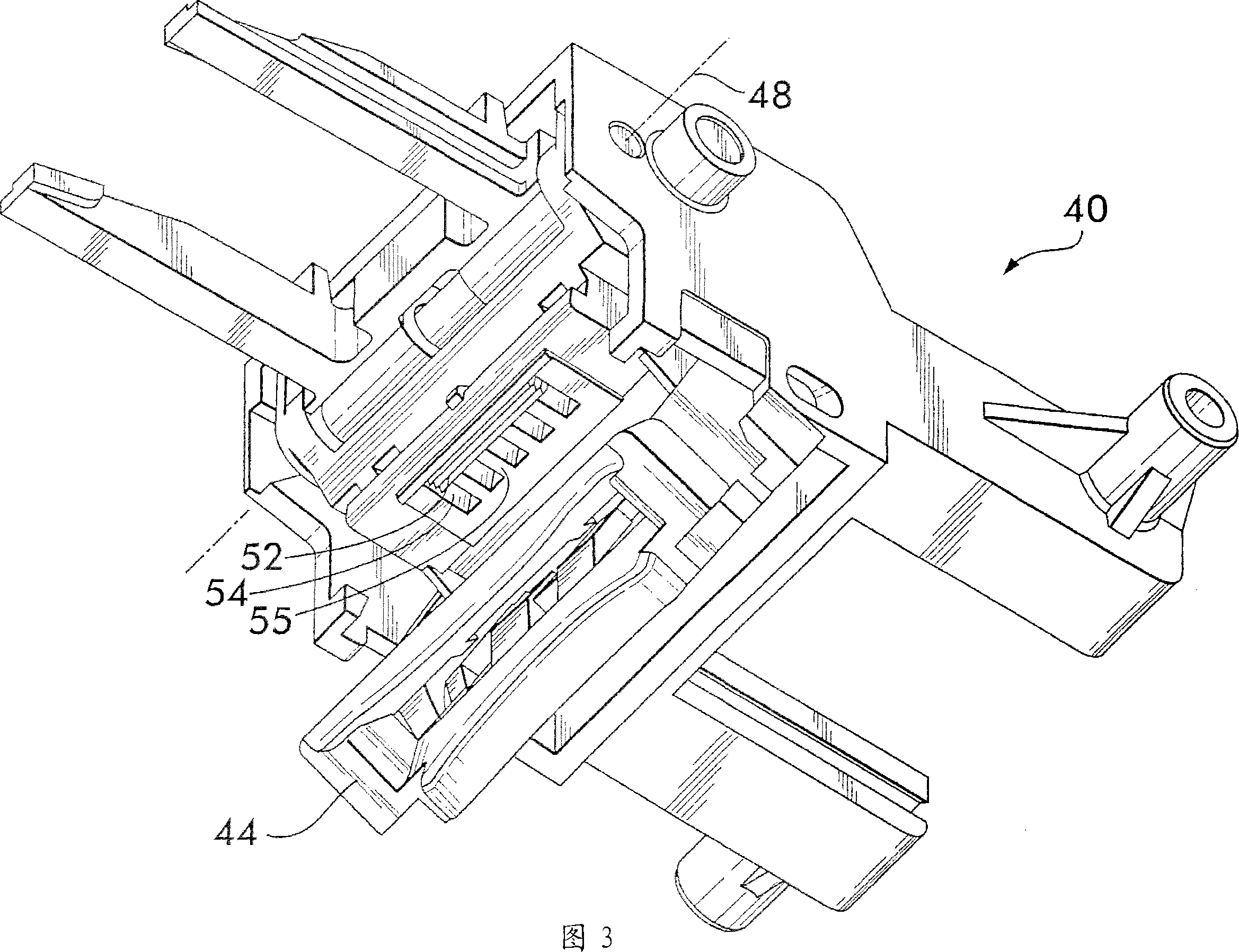

[0022] Except for the structure of the feeding mechanism 19, the manufacturing method of the labeling device of the present invention is the same as that shown in FIG. 6 . Therefore, to avoid repetition, Figures 1 through Figure 5 Only the transfer carriage 40 and its detailed transfer pawls, which are part of the feed mechanism 19 of the labeling device according to the invention, are illustrated. In more detail describe Figures 1 to Figure 5 Previously, the operation of the known labeling device will be described with reference to FIGS. 6 and 7 .

[0023] The labeling device shown in Figure 6 has a housing 11 on which a handle 12 is integrally formed. A compartment 13 is provided on the upper side of the housing to accommodate a supply reel 14 for a carrier web 15 to which self-adhesive labels 16 are glued. The carrier web 15 extends in the labeling device from the supply reel 14 in the compartment 13 to the bottom left as shown in FIG. This deflection extends to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com