Method for predicting melting temperature of coal ash based on mineral phase and neural network composite model

A neural network and composite model technology, applied in the field of predicting coal ash melting temperature, can solve the problems of many steps, time-consuming, high measurement costs, etc., and achieve high accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

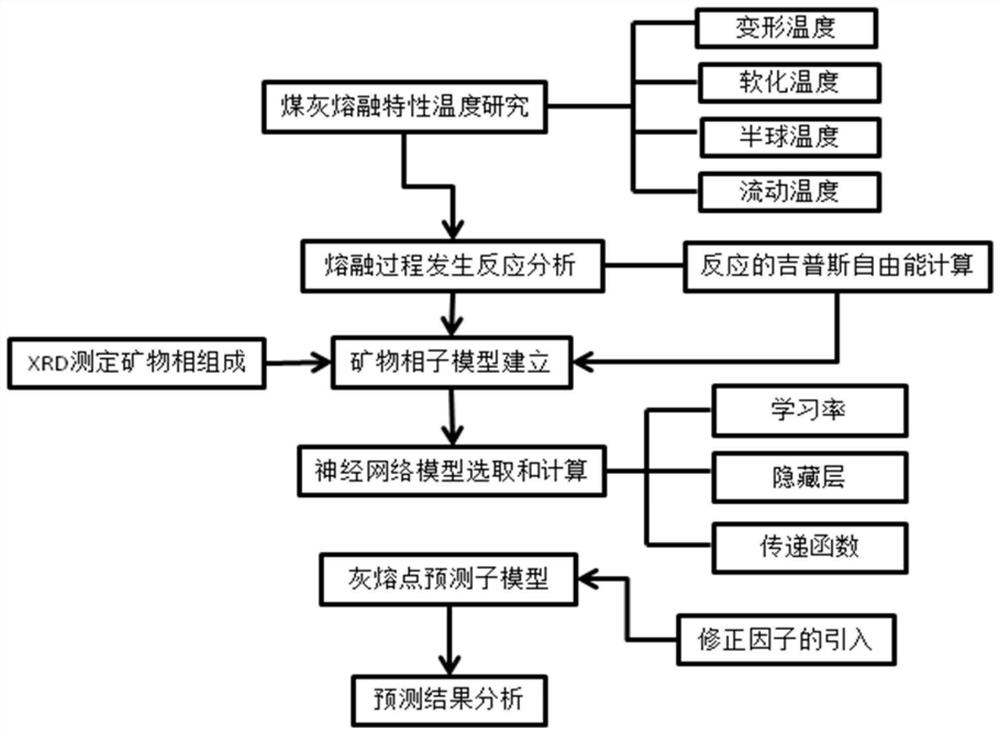

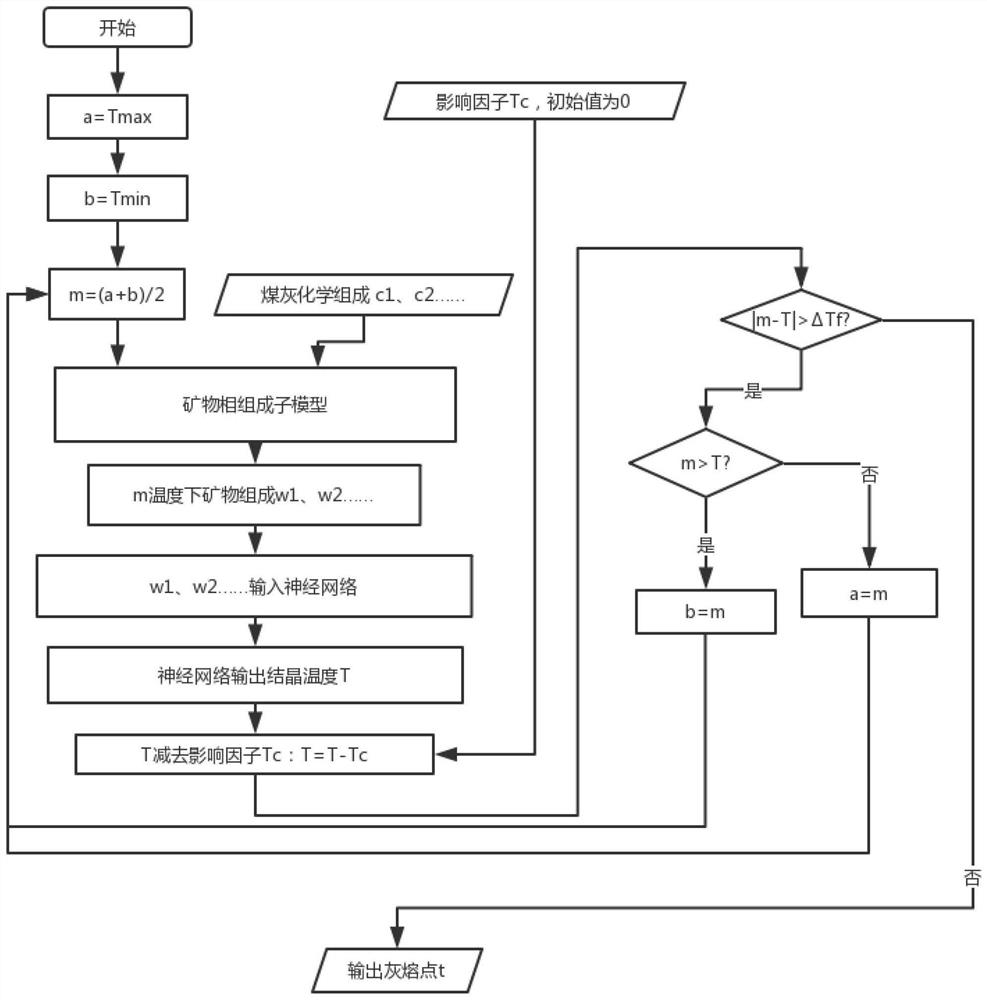

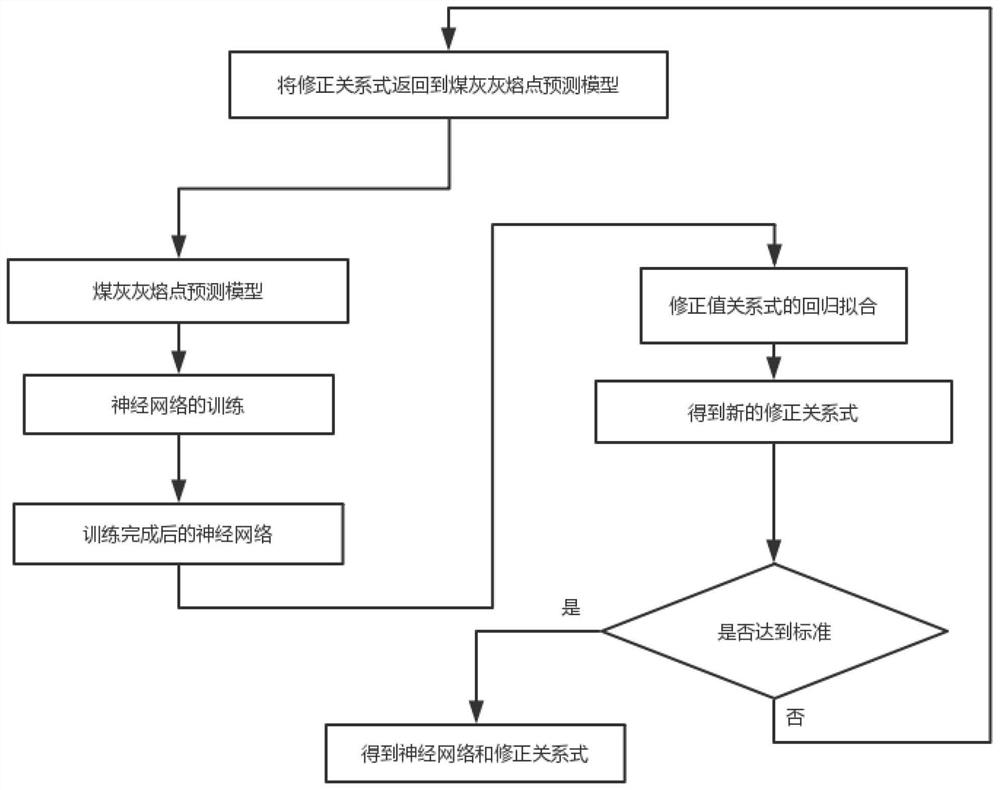

[0035]The invention provides a method for predicting the melting temperature of coal ash based on a composite model of mineral phase and neural network. Firstly, a sub-model of coal ash mineral phase composition is established, and a linear To solve the programming problem, establish a prediction model to solve the coal ash mineral phase composition at a specified temperature, and test the consistency of the model; on the basis of the mineral phase composition sub-model, establish ash melting point prediction sub-model; establish a neural network model to The training parameters of the neural network were adjusted, and the iterative algorithm was used to further enhance the prediction accuracy of the prediction model, and the correction value was added to represent the influence of the secondary elements in the coal ash on the coal ash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com