Momentum type flow sensor probe structure and detection method thereof

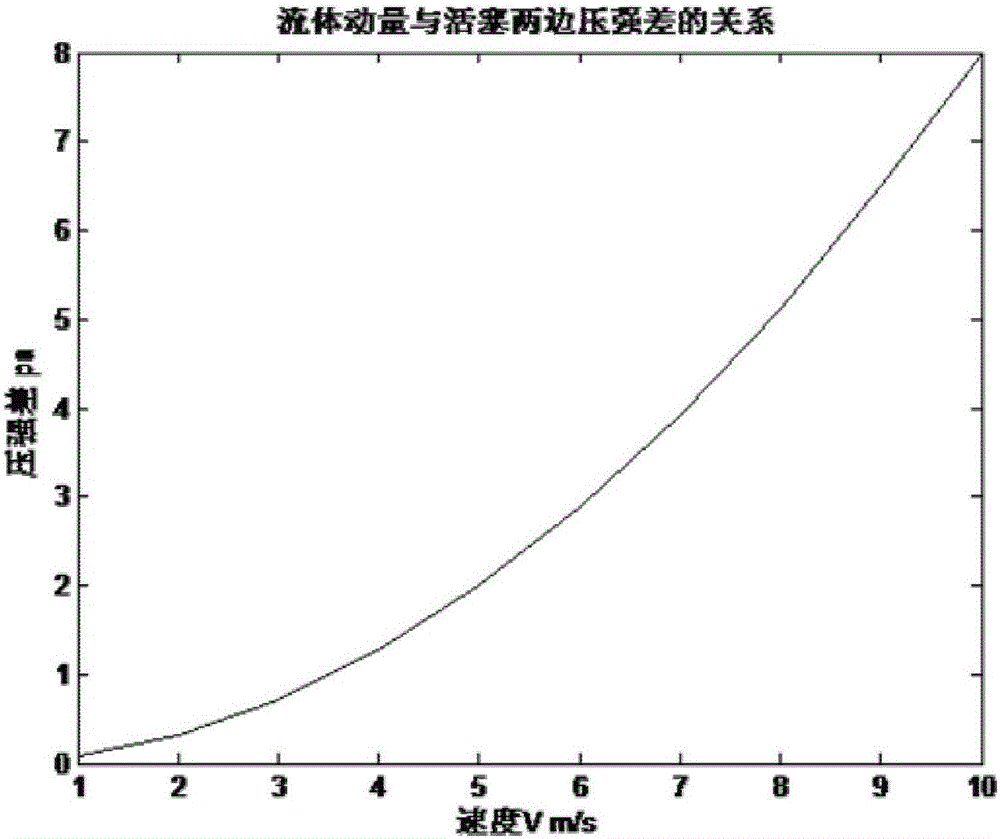

A technology of flow sensor and sensor probe, which is applied in the direction of detecting fluid flow by measuring pressure difference and volume/mass flow generated by mechanical effects, and can solve the problems of incompetence, high energy consumption, and low measurement accuracy, etc., to achieve Improved adaptability and interchangeability, simple intensity compensation principle, and improved detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

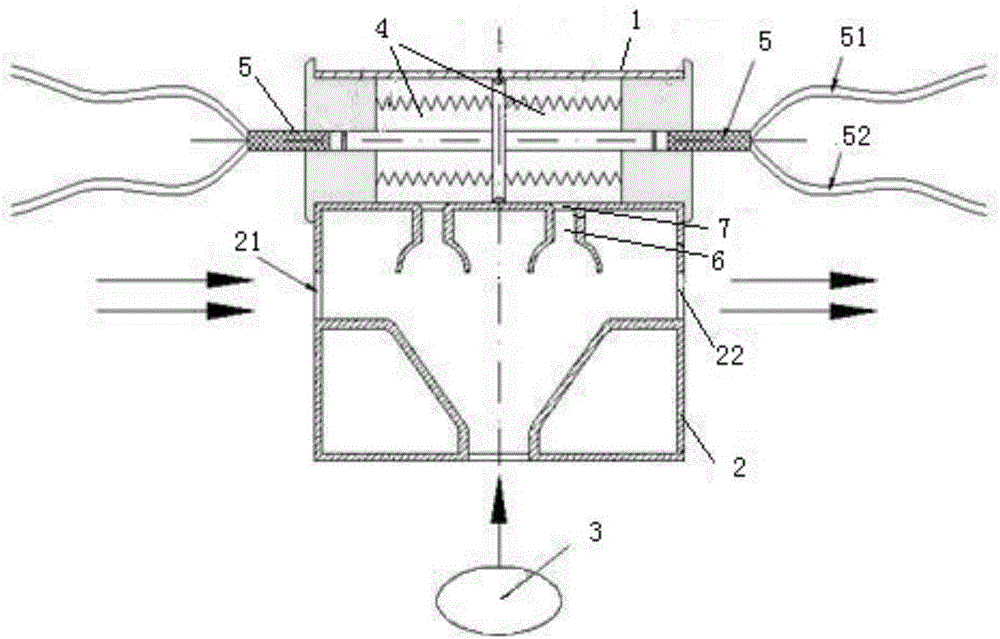

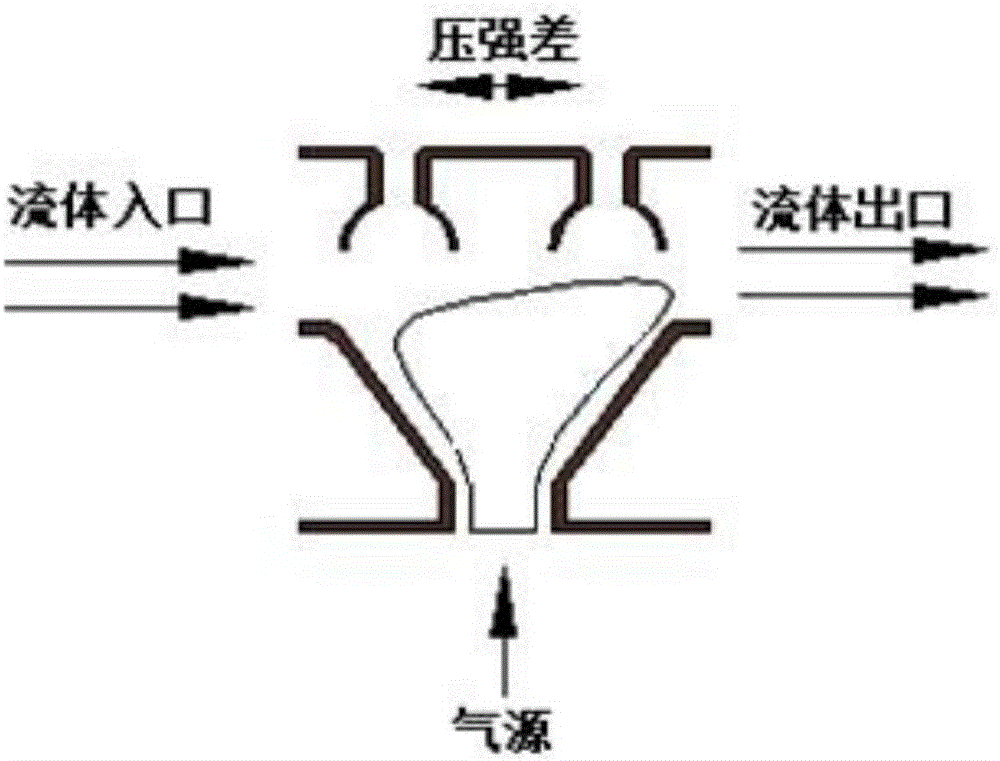

[0024] Reference Figure 1 to Figure 3 This embodiment provides a momentum type flow sensor probe structure, including a differential pressure sensor probe 1, a detection box 2, and a gas source 3. The differential pressure sensor probe 1 has two pressure detection chambers 4, and each pressure detection chamber 4 Correspondingly, a pressure detection port 5 is provided. The pressure detection port 5 is used to detect the fluid pressure in the two pressure detection chambers 4 or the pressure difference in the two pressure detection chambers 4, and the detection box 2 has a fluid inlet 21 and a fluid outlet 22. The fluid flows through the inside of the detection box 2. The detection box 2 and the two pressure detection chambers 4 are respectively connected through a fluid passage 6, and the air supply direction of the air source 3 points to the middle position of the two fluid passages 6, and the fluid passage 6 The air source 3 and the air source 3 are respectively arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com