Heating cooker

A technology for heaters and cookers, which is applied to electric heating fuel, containers with enlarged heating surfaces, lighting and heating equipment, etc., and can solve problems such as overheating, inability to use, and inability to measure the temperature of heated objects correctly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

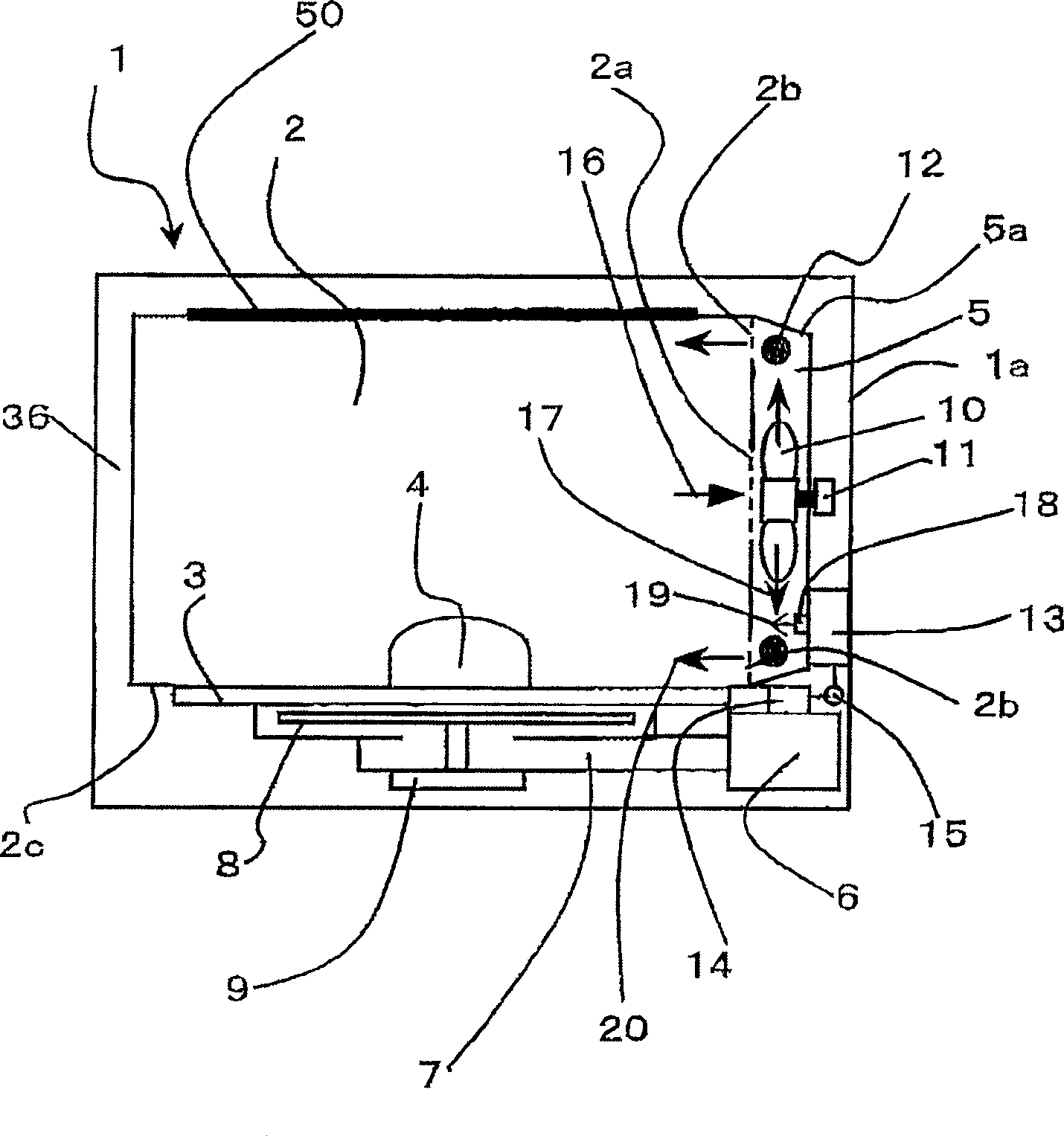

[0035] figure 1 It is a side sectional view of the electric oven cooking range of the present invention.

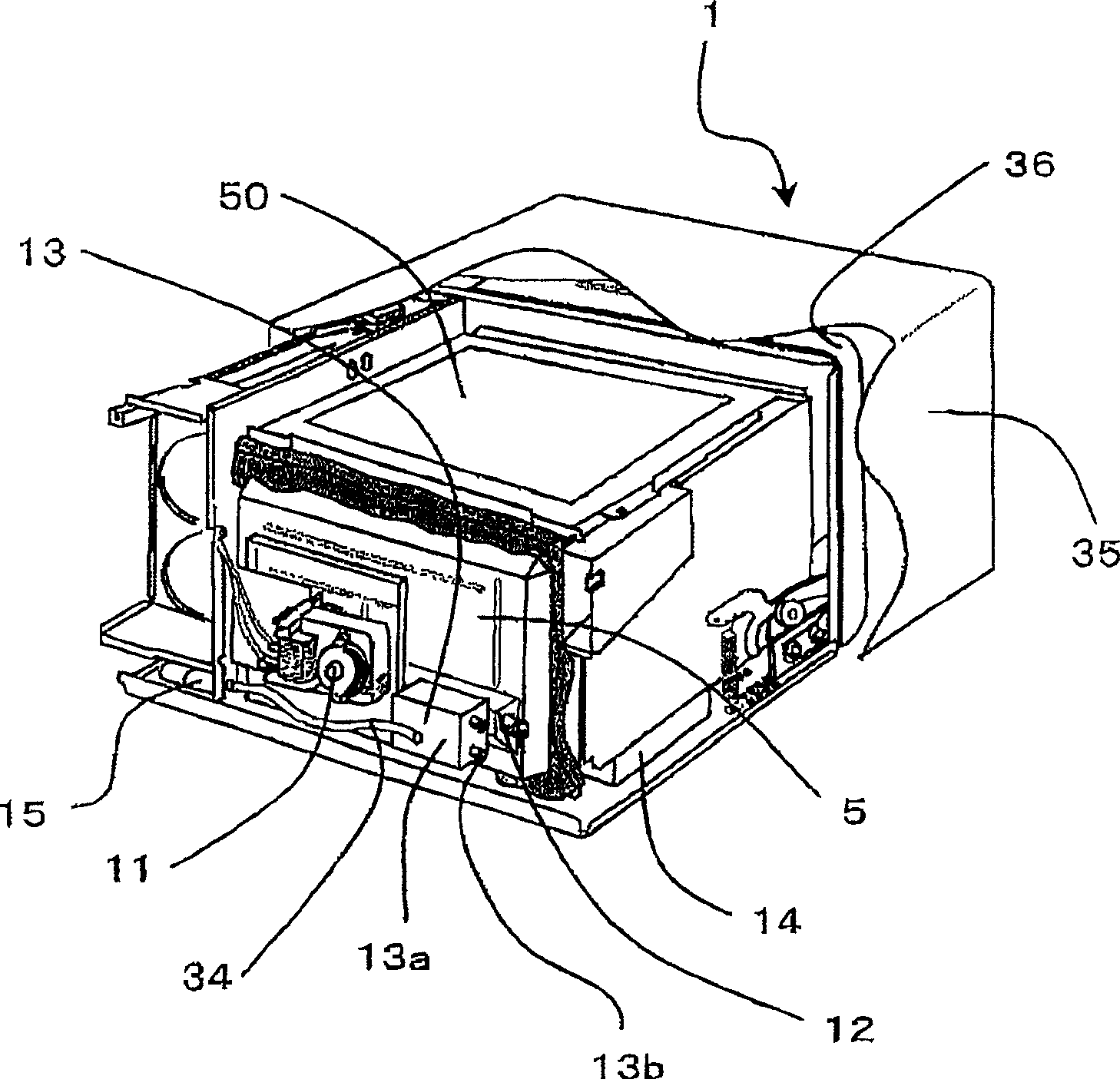

[0036] figure 2 It is a perspective view of this electric oven cooking range as seen from the back side, and it is the state which moved the cover 35 which is an outer frame to the front (door 36 side) of a main body.

[0037] The main body 1 of the electric oven cooking range is composed of the following components: a heating chamber 2 for accommodating food to be cooked 4 such as heated food, and a non-rotating table 3 on the bottom surface 2c of the heating chamber 2 for placing the food 4 , The hot air unit 5 that circulates the hot air in the heating chamber 2, the magnetron 6 as the heating source of the cooking stove heating device, the waveguide 7 that guides microwaves, the rotating antenna 8 and the antenna motor 9 that irradiate the microwave to the heating chamber 2 and so on.

[0038] Since the above-mentioned magnetron 6, wave guide 7, rotating antenna 8 and ...

Embodiment 2

[0074] Figure 4 Is another embodiment of the present invention, and figure 1 It is also a side cross-sectional view of an electric oven cooking range without a turntable. The big difference is that the table 3 placed on the bottom of the heating chamber 2 is separated from the heating chamber 2, and can be freely installed and unloaded from the heating chamber 2. A quality detection device 22 for measuring the weight of the food 4 is installed underneath. Here, although only one first heater 12 is provided near the delivery port 18 of the steam generating device 13 located on the lower side of the hot air unit 5, it may be as figure 1 Shown is divided into two settings, top and bottom.

[0075] Figure 5 It is a perspective view seen from the front side of the cooking range of the electric oven, with the cover as the outer frame removed.

[0076] According to this structure, it is characterized in that the mass detection device 22 detects the weight of the food 4 on the table...

Embodiment 3

[0109] Picture 9 It is another embodiment of the present invention, which is different from the above-mentioned embodiment. It is a side cross-sectional view of a rotary table type electric oven cooking range in which the rotary table 32 on which the object to be cooked 4 is placed in the center of the heating chamber 2 is freely rotatable, The structure is that the microwave generated from the magnetron 6 is irradiated to the object 4 to be cooked from the side of the heating chamber 2 through the waveguide 7.

[0110] The turntable 32 is rotated by a turntable motor 33 located at the lower part of the turntable, and a quality detection device 22 is provided at the end of the same axis. The quality detection device 22 can be used to detect the weight of the food 4 placed on the turntable 32. The quality detection signal 23 is sent to the control device 27. The cooking method is the same as the above description.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com