Drive device for combing machine

A driving device and combing machine technology, which is applied in the field of combing machines to achieve the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

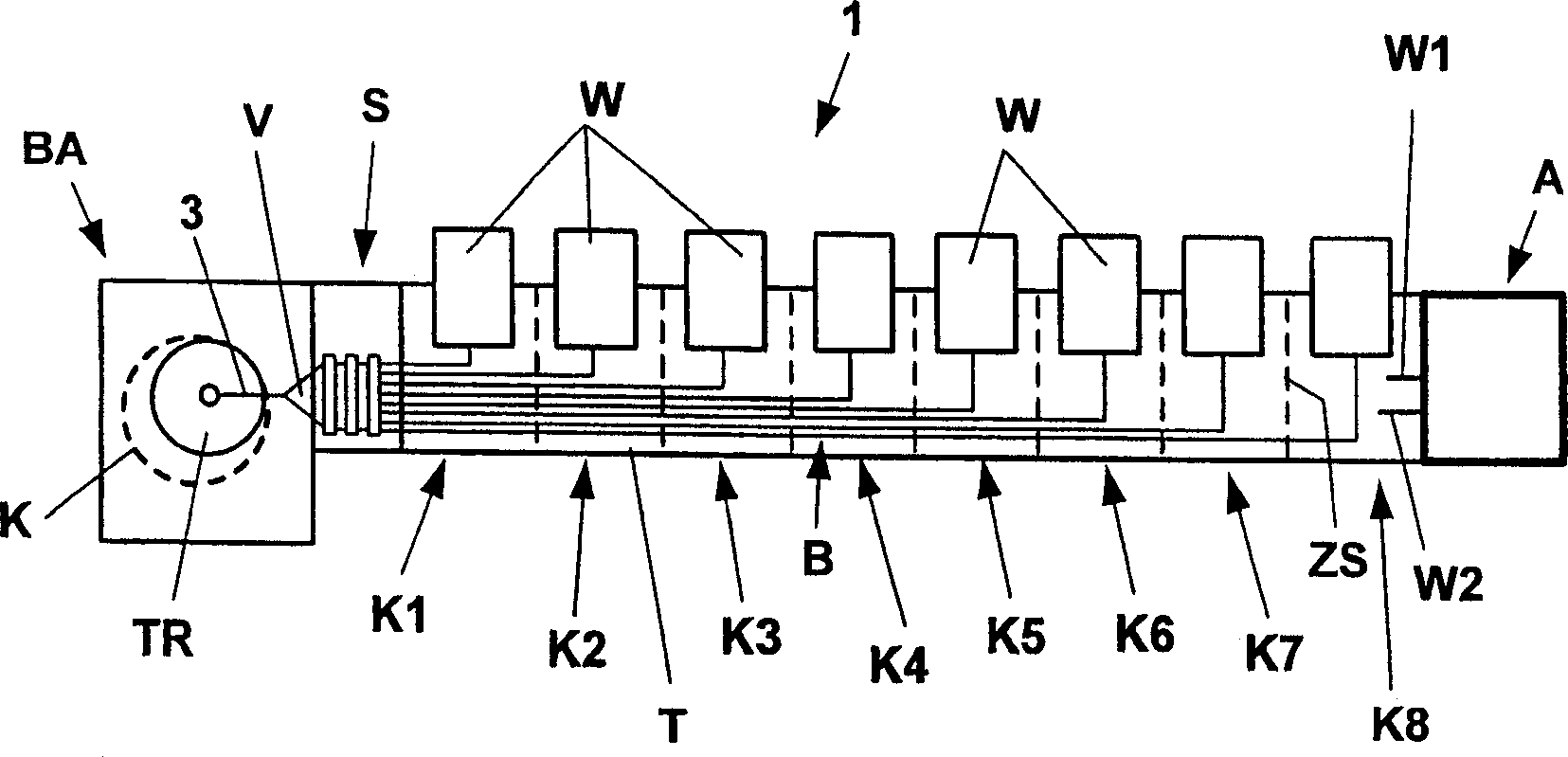

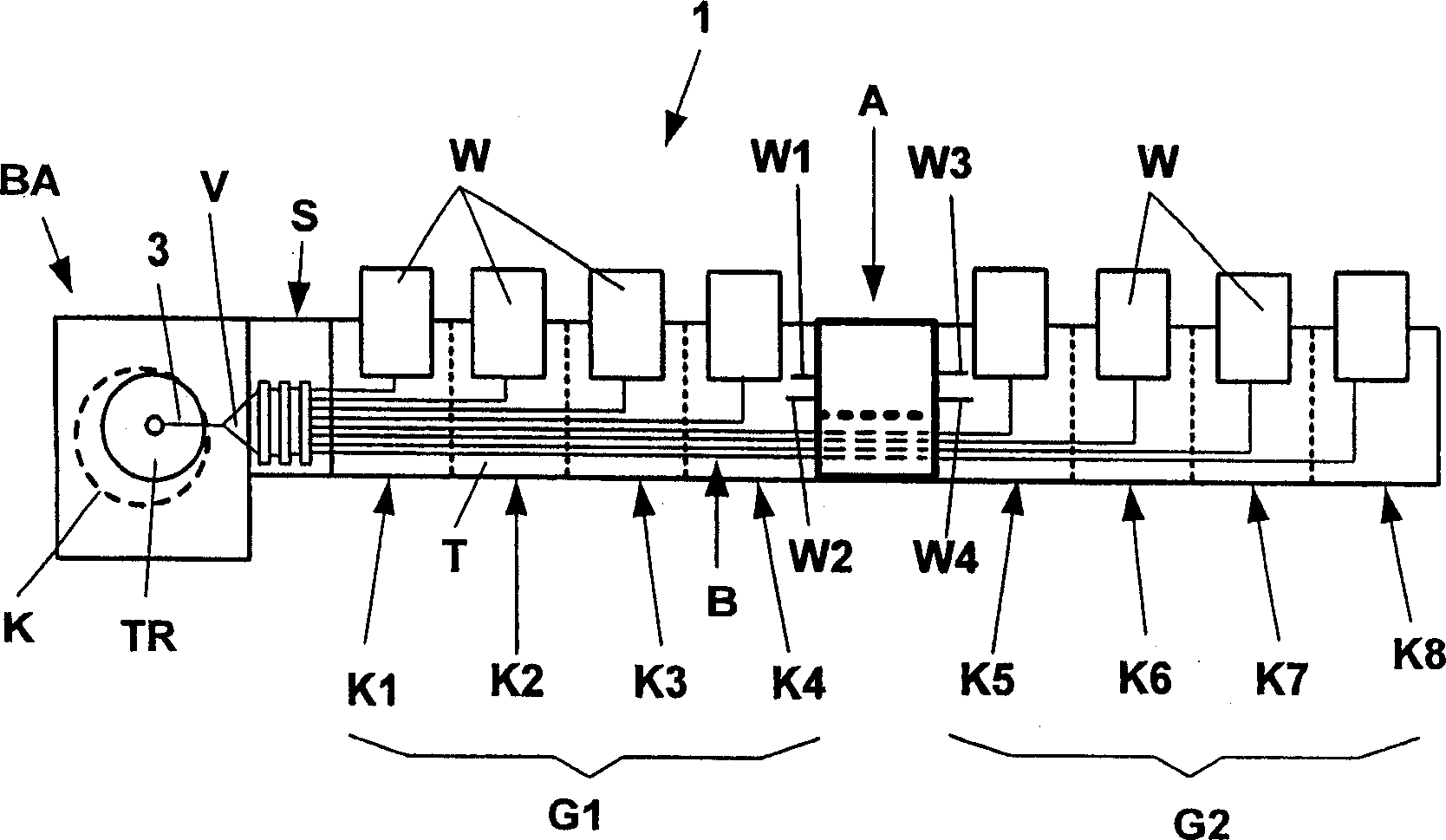

[0032] figure 1 is a plan view of a known combing machine 1 with a total of eight combing heads K1 to K8 arranged next to each other, each combing head having a lap roller W for processing in front of it. The individual devices of the combing heads K1 to K8 (such as clamps, circular combs, detaching rollers, lap rollers, transfer rollers, etc.) are driven by drive A via shafts extending longitudinally to the combing heads, schematically shown in the figure Two of these axes are W1 and W2. The driving device A basically includes a main motor and a transmission. In the case of a combing head, generally a "gage" and a plurality of gauges may be involved, which together form a longitudinal section of the combing machine for the carding process of the fibrous material.

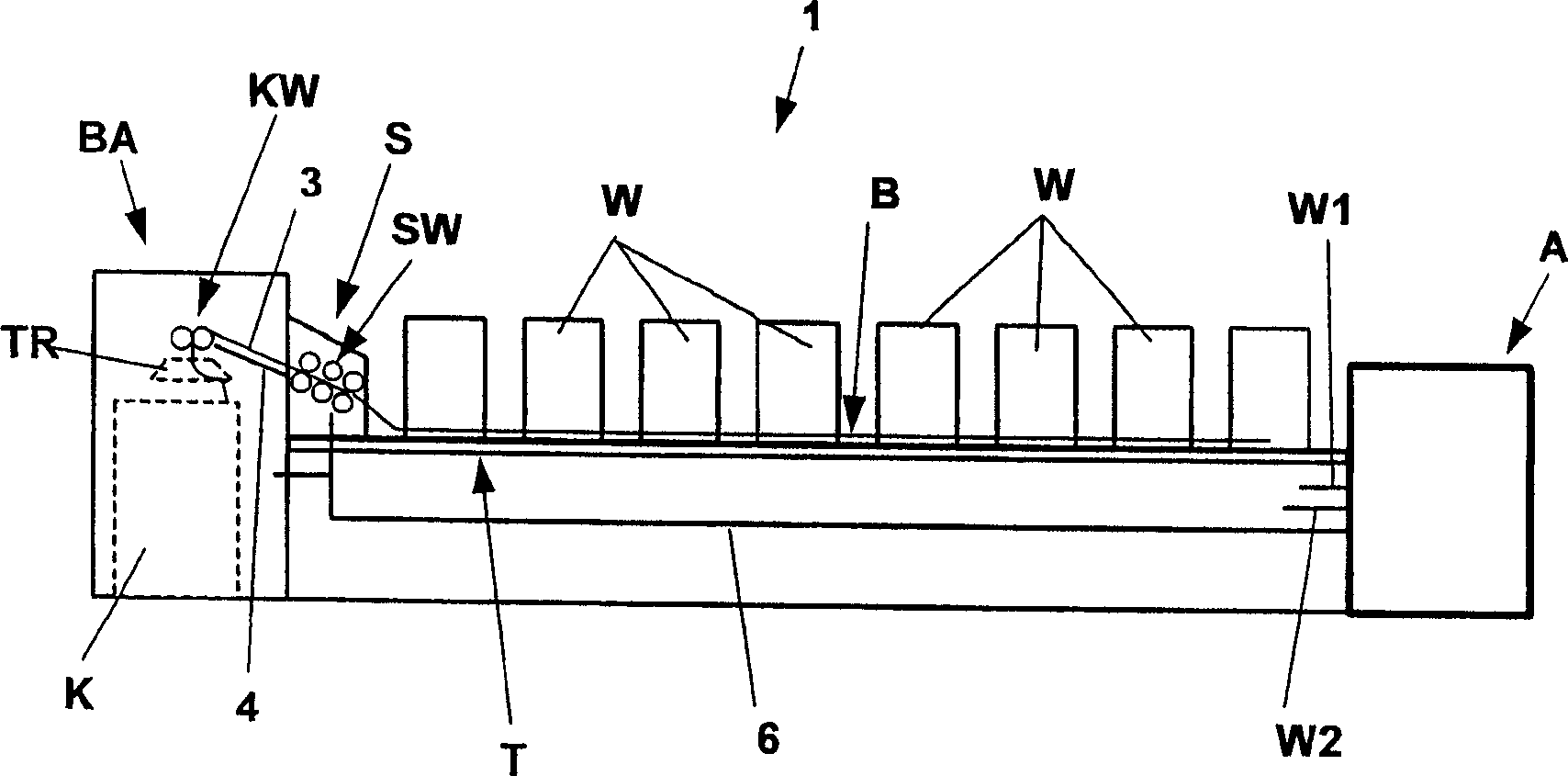

[0033] Above the table T, the sliver B formed at the individual combing heads K1-K8 is guided to the drafting device S. especially if image 3As shown in , the table T guides the sliver B obliquely upwards. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com