Drive device for ultrasonic linear motor

A driving device and linear motor technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, piezoelectric devices/electrostrictive devices, etc., can solve the problems of fast wear, short life, Large wear and tear of sliding parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

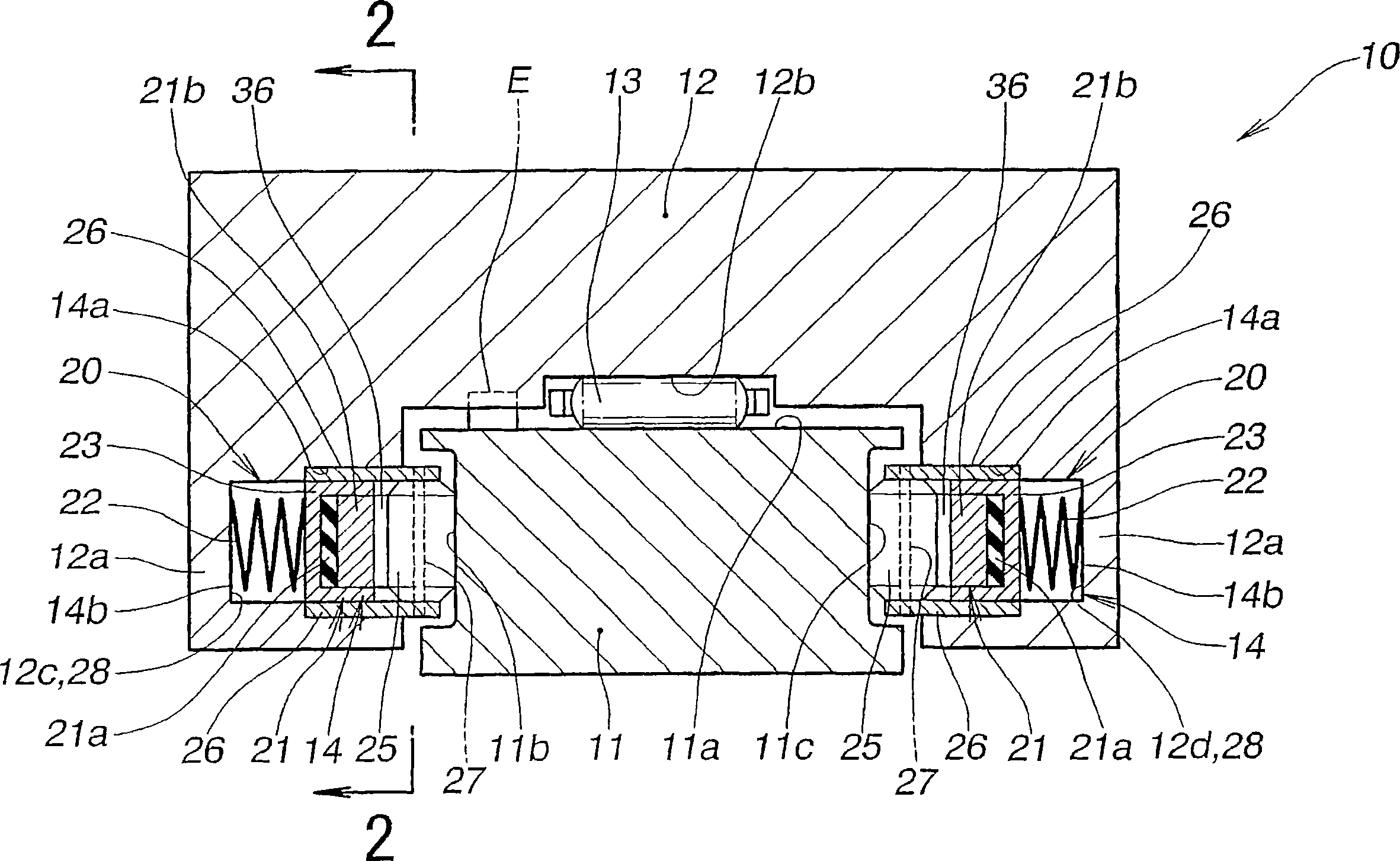

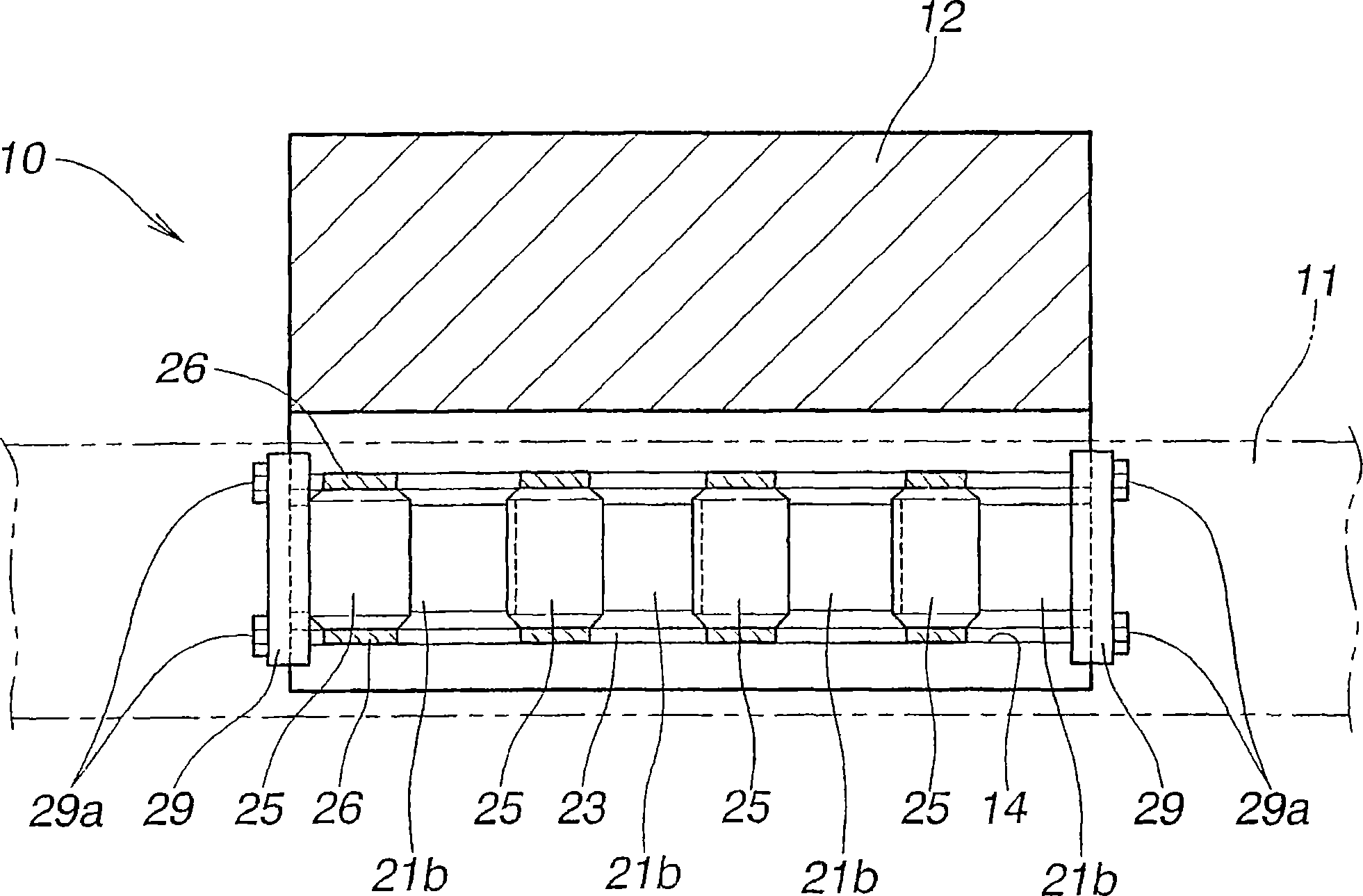

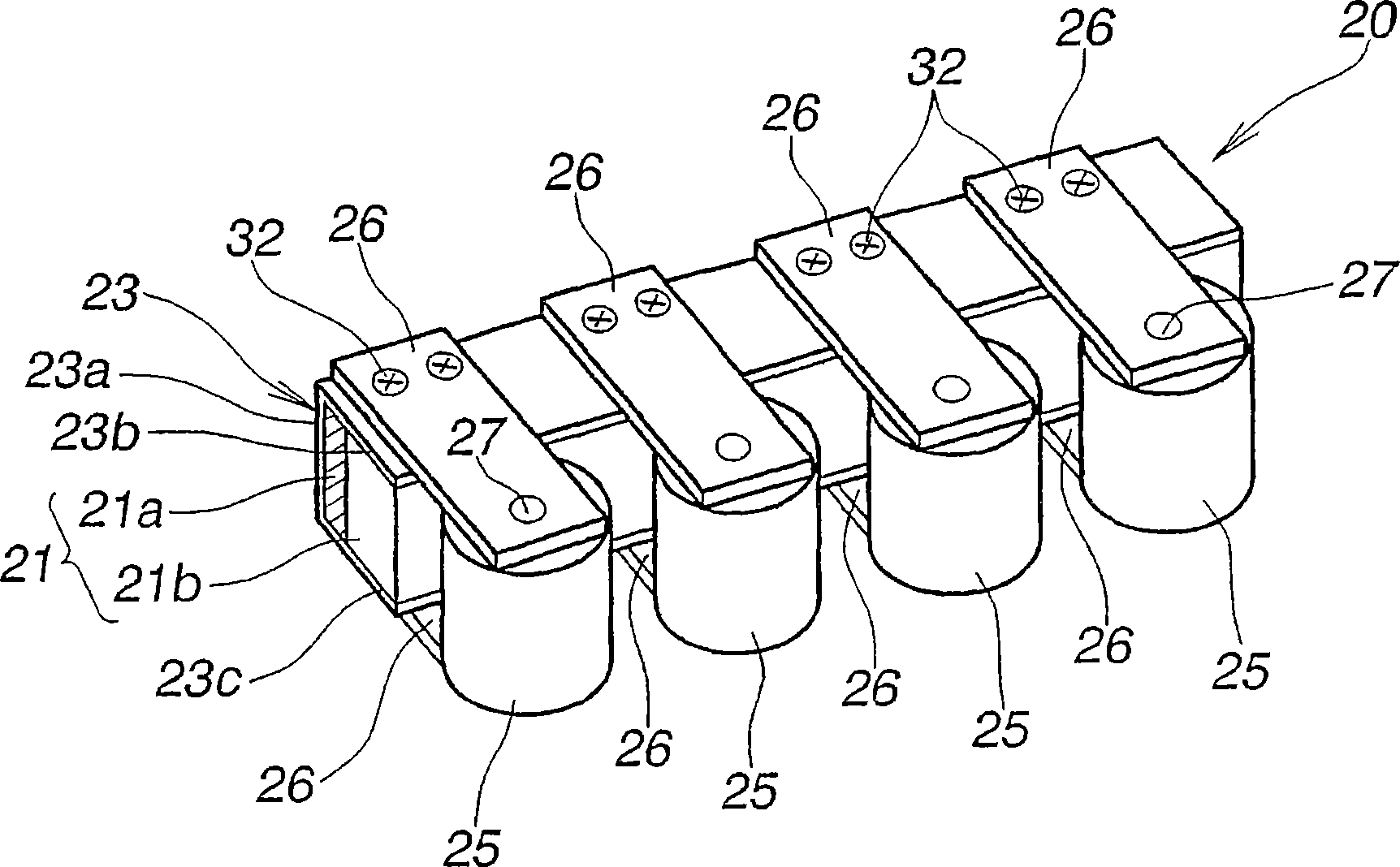

[0025] figure 1 , figure 2 and image 3 A linear motor driving device 10 and a driving section 20 according to a first embodiment of the present invention are shown. The driving device 10 of the first embodiment is composed of a rail 11 , a base body 12 movably mounted on the rail 11 , and left and right driving portions 20 , 20 provided on the base body 12 .

[0026] The base body 12 is U-shaped in section and has left and right leg portions 12a, 12a, and the base body 12 surrounds the top surface 11a and the side surfaces 11b, 11c of the rail 11, and applies a load to the rail through a plurality of rod bearings 13. 11 on the top surface 11a. The leg portions 12a, 12a of the base body 12 have supporting holes 14, 14 for supporting the driving portions 20, 20. The supporting holes 14 , 14 have open sides facing the side surfaces 11 b , 11 c of the rail, and are formed in the lengthwise direction of the base body 12 . The support hole 14 is composed of a first support ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com