Optical detecting instrument of defects in glass

A technology for optical detection and glass defects, applied in measurement devices, material analysis by optical means, scientific instruments, etc., can solve problems such as difficulty in correctly identifying defects, and achieve the effect of avoiding background interference, easy to implement, and simple to install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the technical solution of the present invention, a further detailed description will be made below in conjunction with the accompanying drawings.

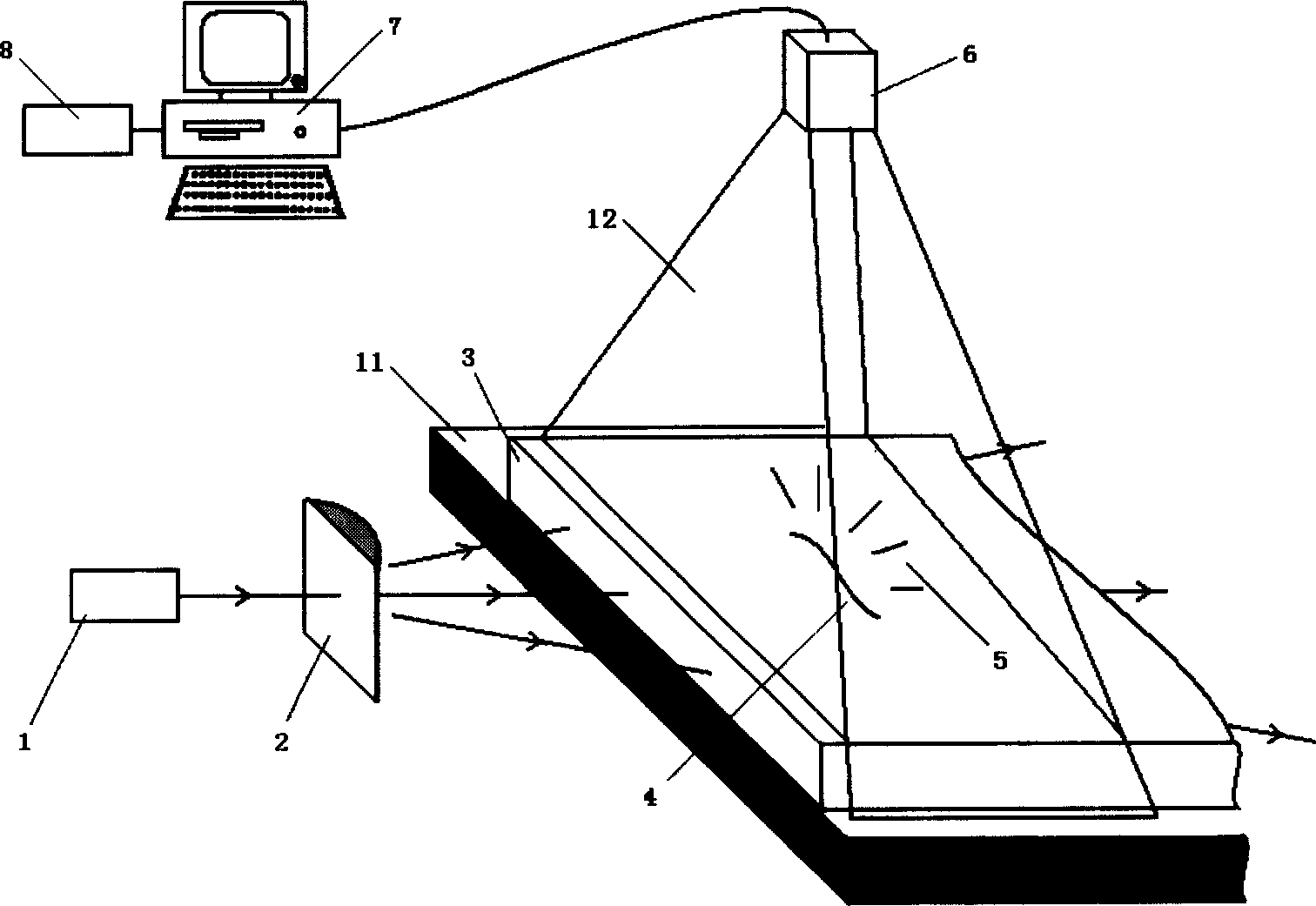

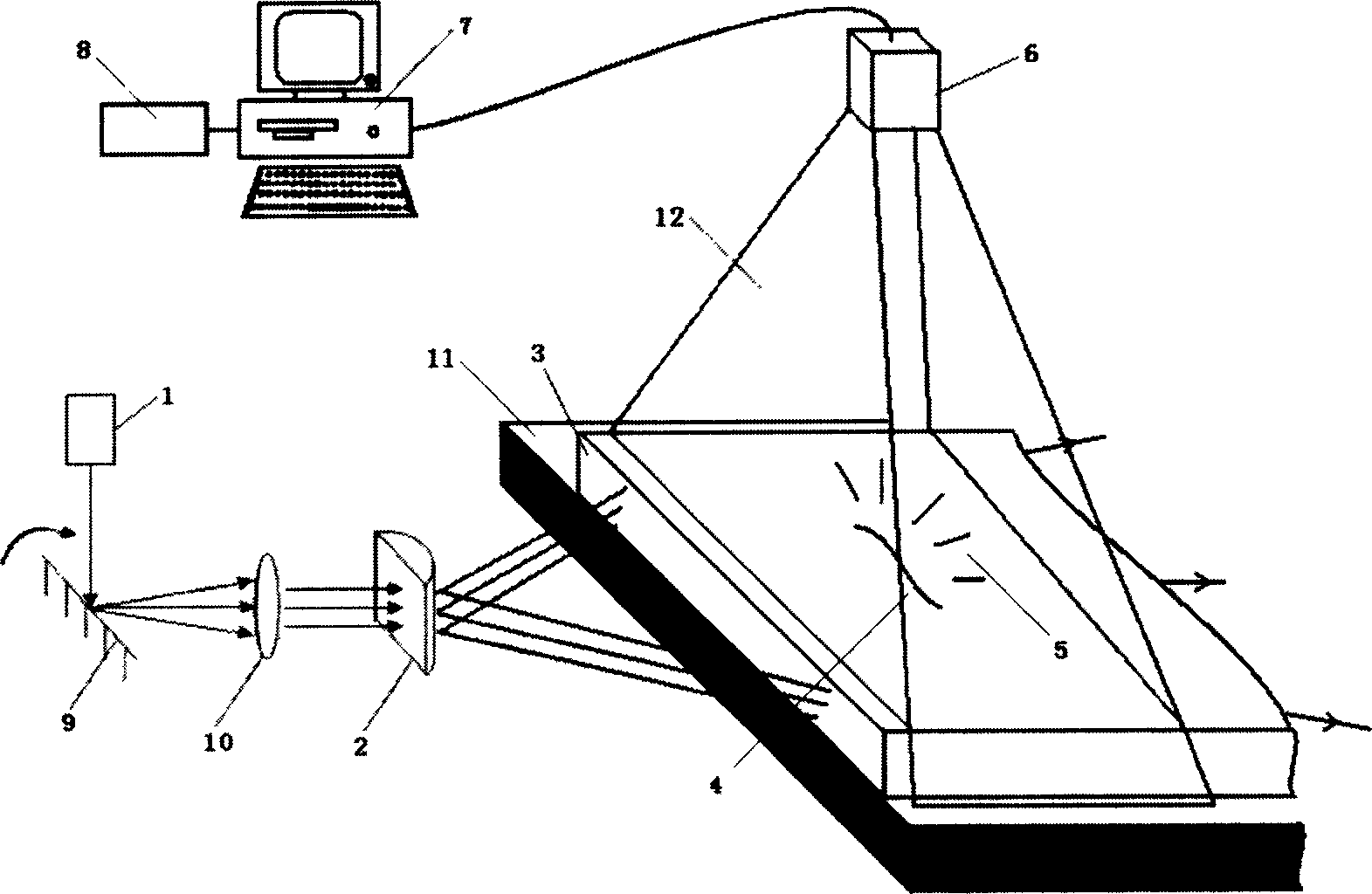

[0027] The structural composition and working principle of the optical detection device for glass defects of the present invention are as follows: figure 1 As shown, the detection device includes a laser 1 , a cylindrical mirror 2 , an object loading platform 11 , a shading cover 12 , a glass to be inspected 3 , a camera 6 (or a digital camera), a computer 7 and image processing and recognition software 8 .

[0028] The inspected glass 3 is placed on the loading platform 11, and the camera 6 is positioned above the loading platform 11. The light shield 12 is connected with the camera 6 around the area of the inspected glass to block the background light. The camera 6 is connected to the computer 7, and the computer 7 Built-in camera control and image processing and recognition software8. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com