Porous membrane microstructure devices and methods of manufacture

一种微结构、多孔膜的技术,应用在化学仪器和方法、膜、膜技术等方向,能够解决高成本、多孔膜应用限制、阻碍大规模生产等问题,达到低制造成本、有利于平行化、优良产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Detailed description of the preferred embodiment

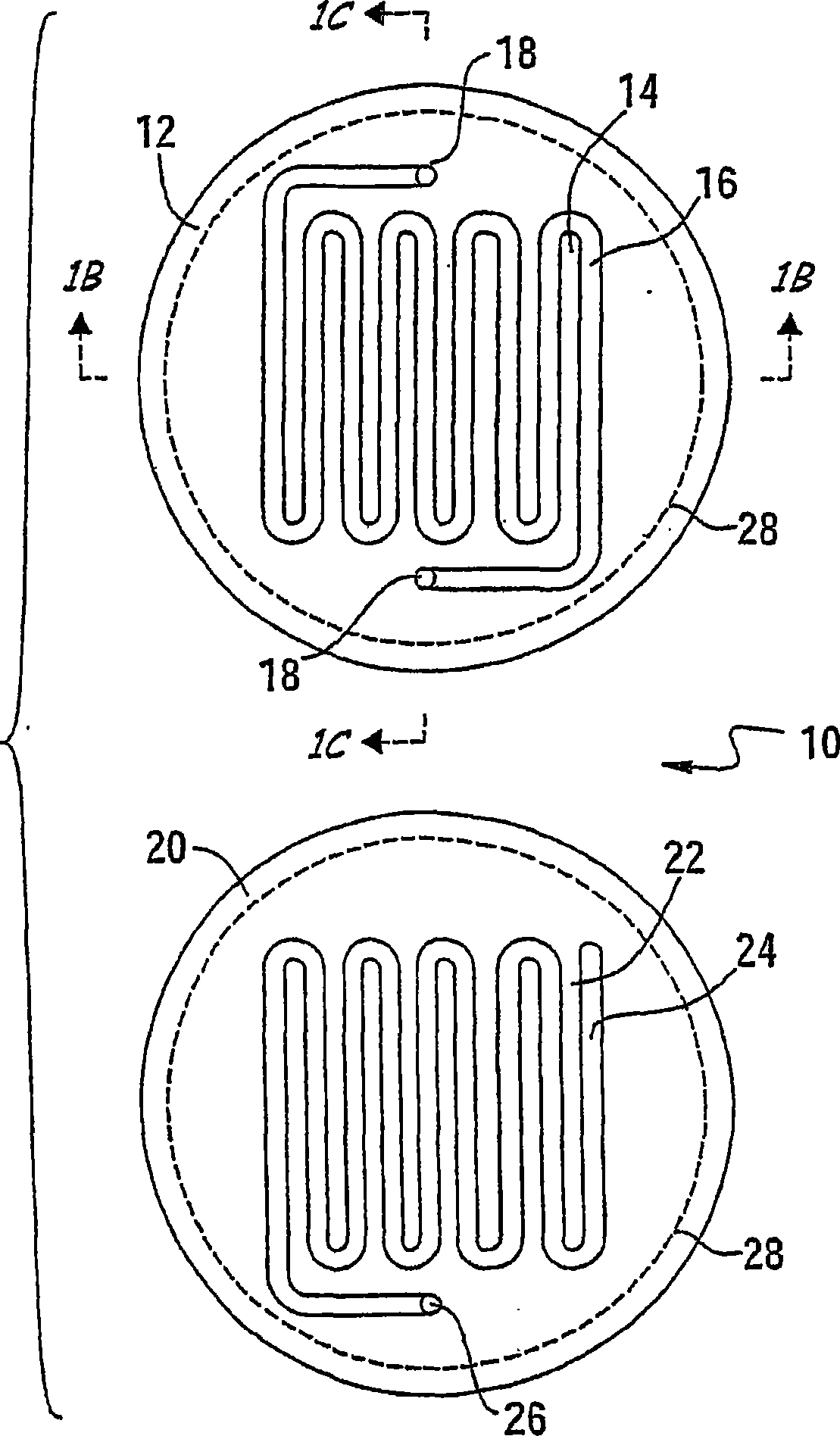

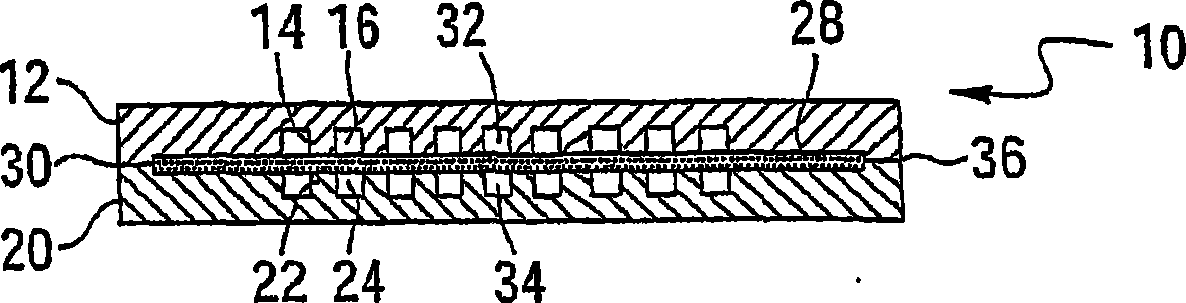

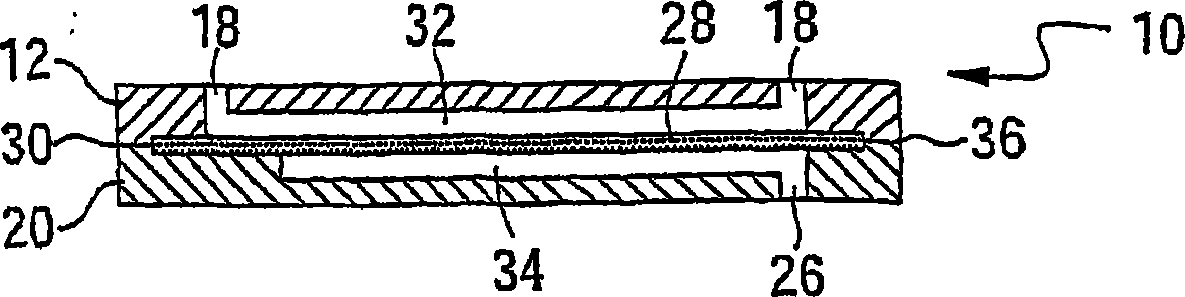

[0026] The disclosed porous membrane microstructure devices can be used in separator, extractor, diffuser and contactor applications. Conventional micro-lamination processing steps are not required when manufacturing the porous membrane microstructure device, which obviously saves cost. The overall configuration of the disclosed porous membrane microstructure provides, among other functions, sufficient mechanical support for the porous membrane and substantially eliminates leakage during chemical processing. The disclosed method for fabricating porous membrane microstructures combines low fabrication costs, facilitates parallelization, and yields devices that provide excellent yields.

[0027] The present invention broadly relates to membrane microstructures and methods of making them. Such membrane microstructures are particularly suitable for chemical processing applications and may be configured to facilitate catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com