Method of optical isomer separation with use of supercritical fluid chromatography

A technology of optical isomers and separating agents, applied in the field of chromatographic columns, can solve problems such as difficult separation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

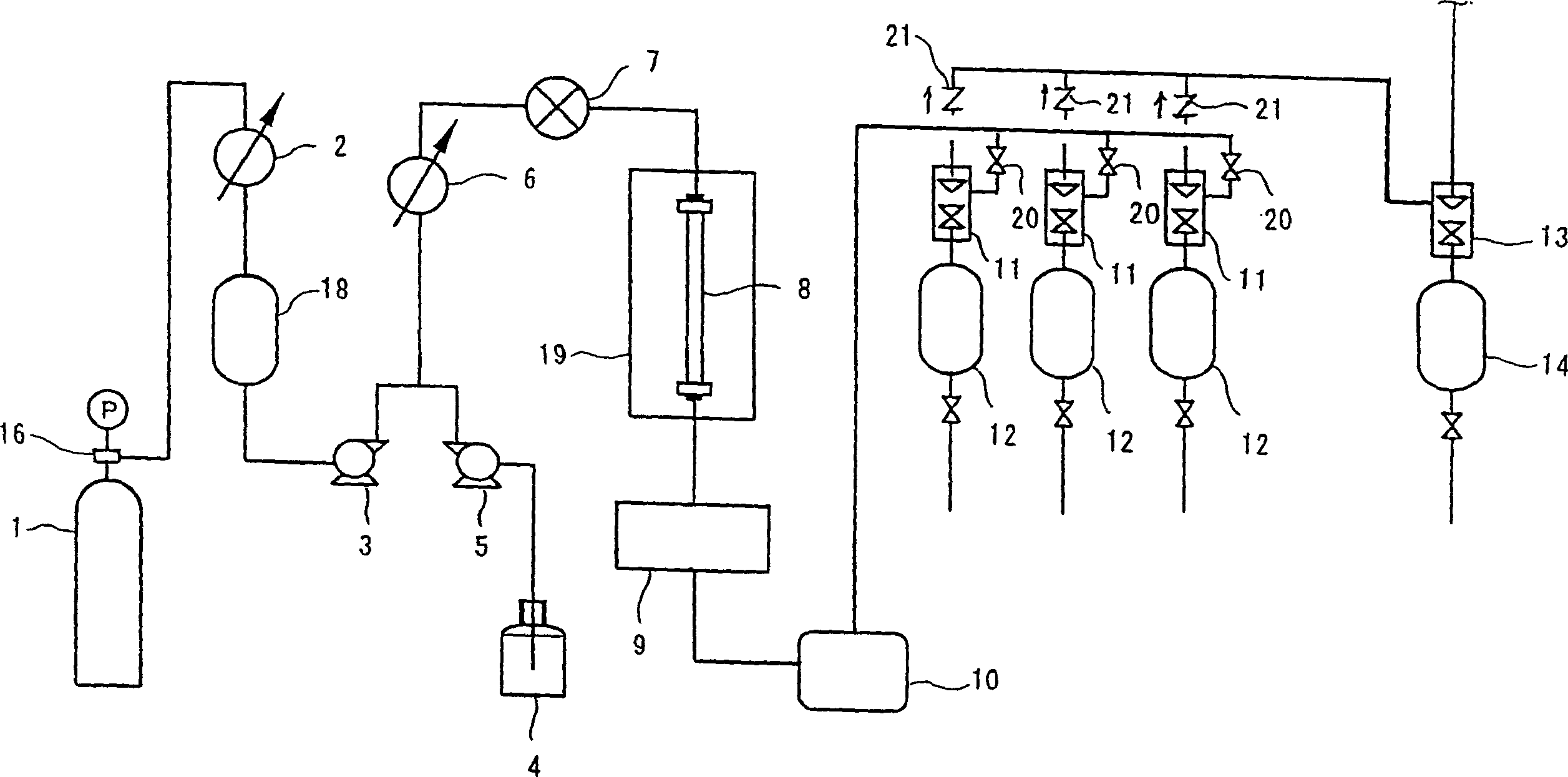

Method used

Image

Examples

example 1

[0062] 10 g of cellulose tribenzoate polymer (hereinafter also referred to as "OB polymer") was dissolved in a mixed solvent containing 500 ml of methylene chloride and 50 ml of n-hexanol to obtain an OB polymer solution.

[0063] Meanwhile, 2.5 g of sodium dodecylbenzenesulfonate (Tokyo Chemical Industry Co., Ltd.) was dissolved in 1,000 ml of purified water to prepare an aqueous solution. The OB polymer solution was added dropwise to the aqueous solution over a period of 4.6 hours (dropping rate: 2 ml / min), maintaining the aqueous solution at 15° C. during the dropping, and stirring the solution at a rate of 500 rpm.

[0064] After the dropwise addition process was completed, stirring was continued at the same rate, and the temperature of the aqueous solution was adjusted to 40° C., and nitrogen gas was flowed to distill off methylene chloride. Then, the obtained product was left to stand, and finally the OB polymer particles were obtained from the aqueous solution.

[0065...

Embodiment 1

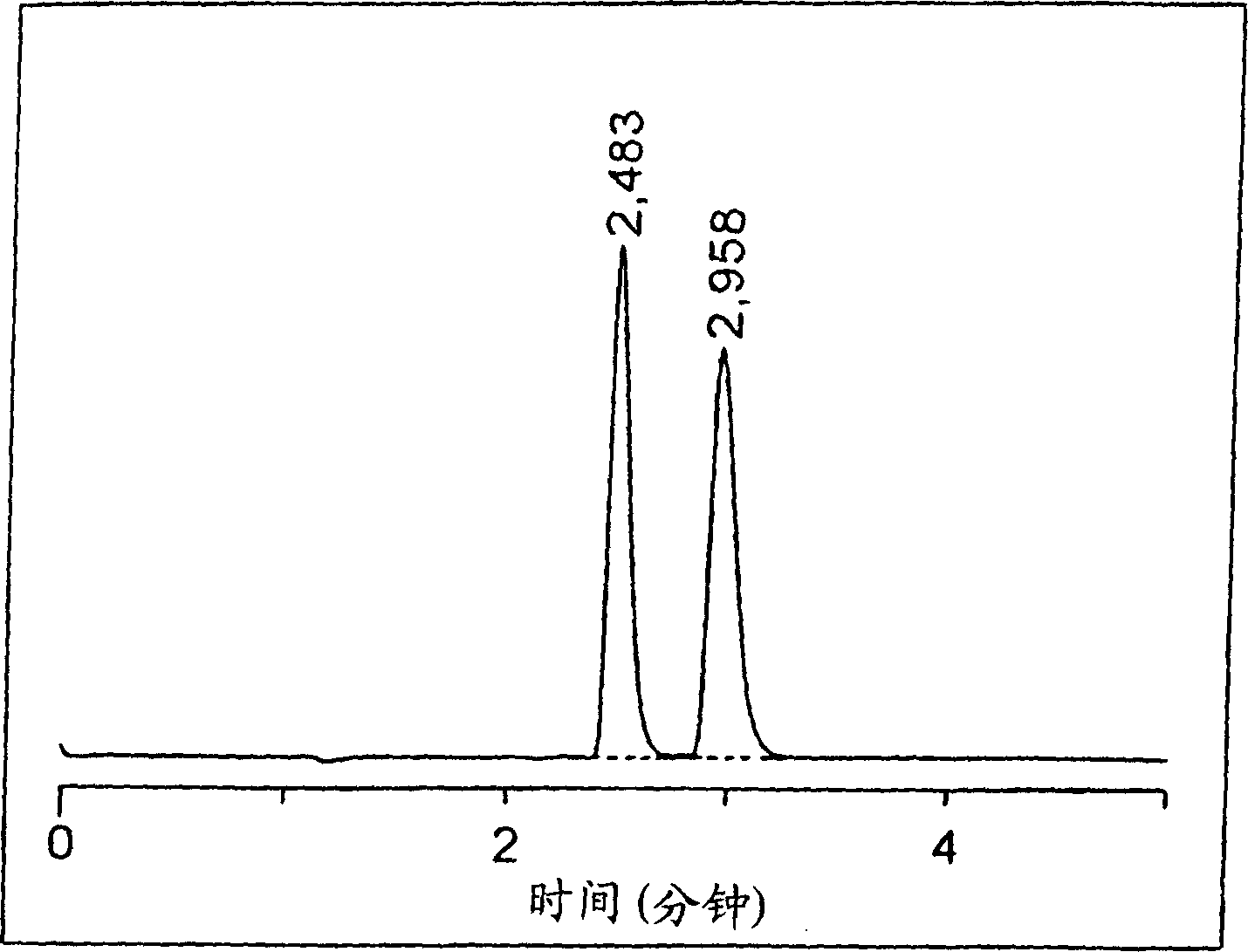

[0098] Of the column 1 - column 3 each filled with the optical isomer separating agent formed of polymer particles thus obtained, the column filled with the optical isomer separating agent 1 formed of OB polymer particles 1 is used to separate optical isomers in supercritical fluid chromatography. The methanol solution of trans-stilbene oxide was used as the separation sample, and the optical resolution of trans-stilbene oxide was carried out under the following conditions. figure 2 Chromatograms obtained in optical resolution are shown.

[0099] (separation condition)

[0100] Mobile phase: CO 2 / methanol=90 / 10(v / v)

[0101] Flow rate: 3.0mL / min

[0102] Pressure: 15MPa

[0103] Column temperature: 25°C

[0104] Detection: UV230nm

[0105] Column size: 0.46mm I.D.×250mmL

[0106] Injection volume: 10μg

[0107] (Note that the injected amount refers to the mass of the optical isomer mixture of trans-stilbene oxide in the separated sample.)

[0108] figure 2 It was...

Embodiment 2

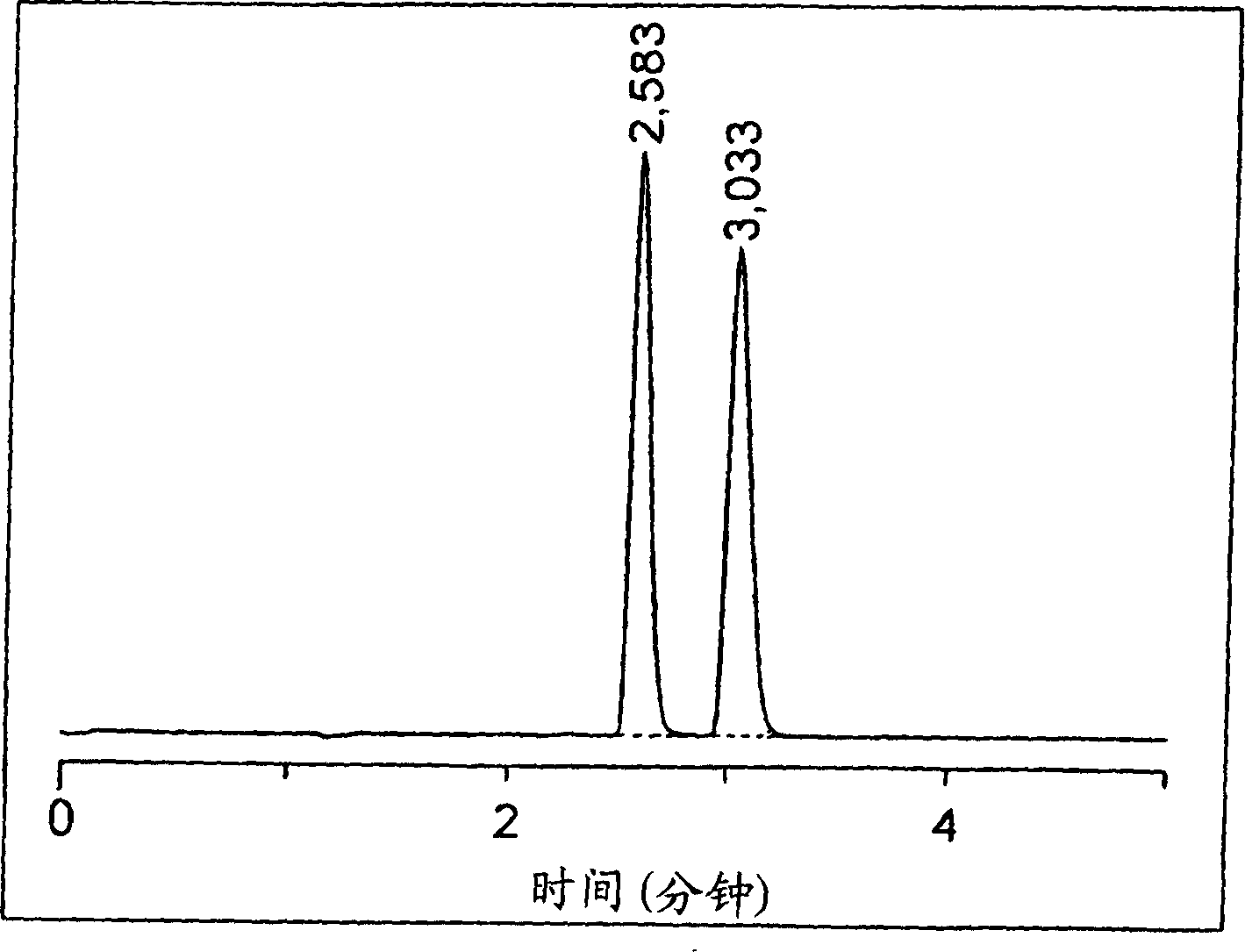

[0113] Optical resolution of trans-stilbene oxide was performed in the same manner as in Example 1, except that the detection wavelength was changed to 254 nm, and the injection amount was changed to 400 μg, 500 μg, and 700 μg. Figure 4-6 Chromatograms obtained in optical resolution are shown.

[0114] Figure 4-6 Shows that during the optical resolution of trans-stilbene oxides by supercritical fluid chromatography using column 1 packed with OB beads, trans-stilbene oxides can be clearly detected in a short period of time even when the injection volume is increased The peaks of each optical isomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com