Hexagon funnel

A hexagonal, funnel technology, applied in the funnel, bottle filling, packaging and other directions, can solve the problems of user inconvenience, air cannot be discharged to the outside, easy to be pushed out by the gas in the bottle, etc., to achieve practical convenience, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

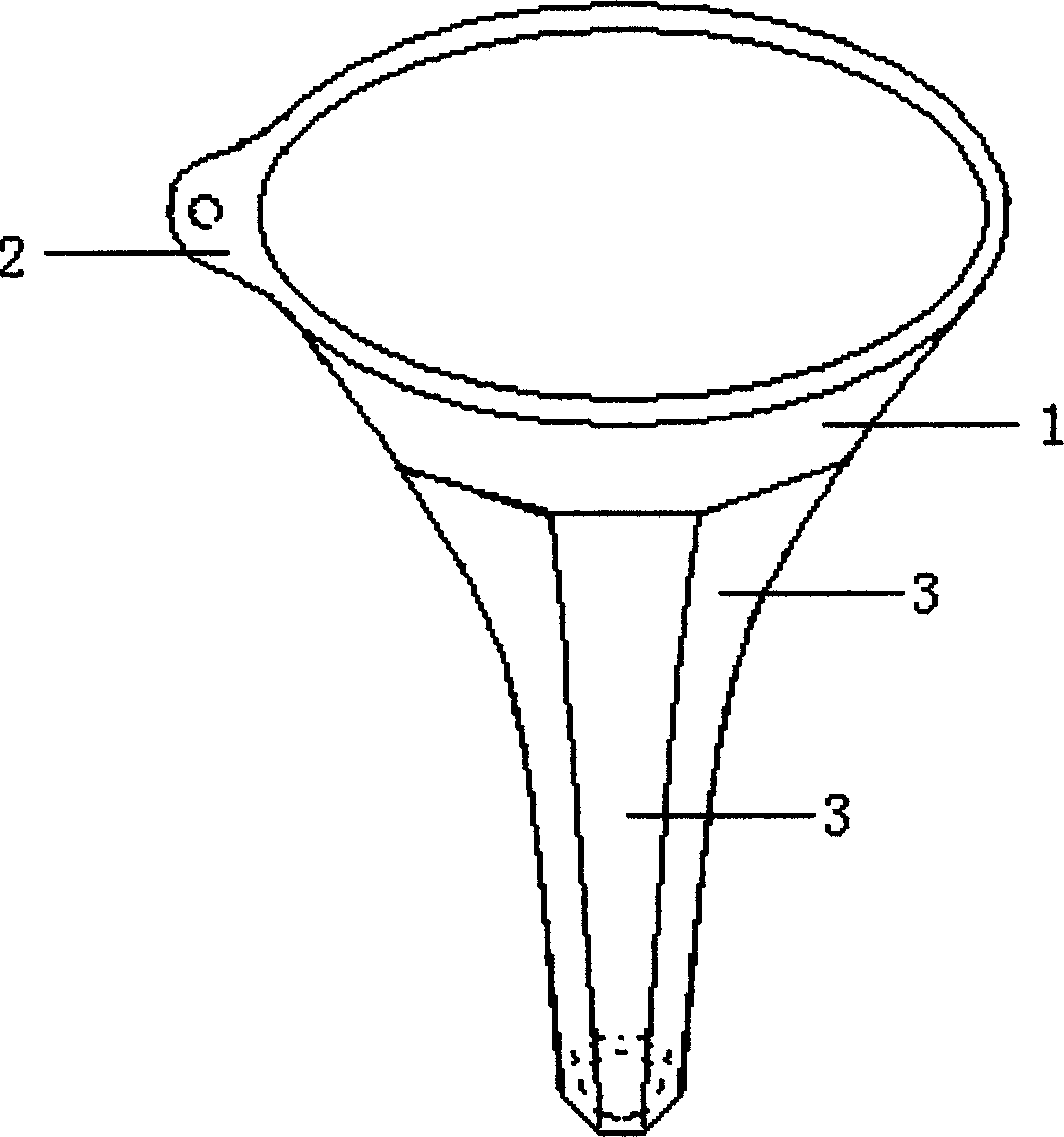

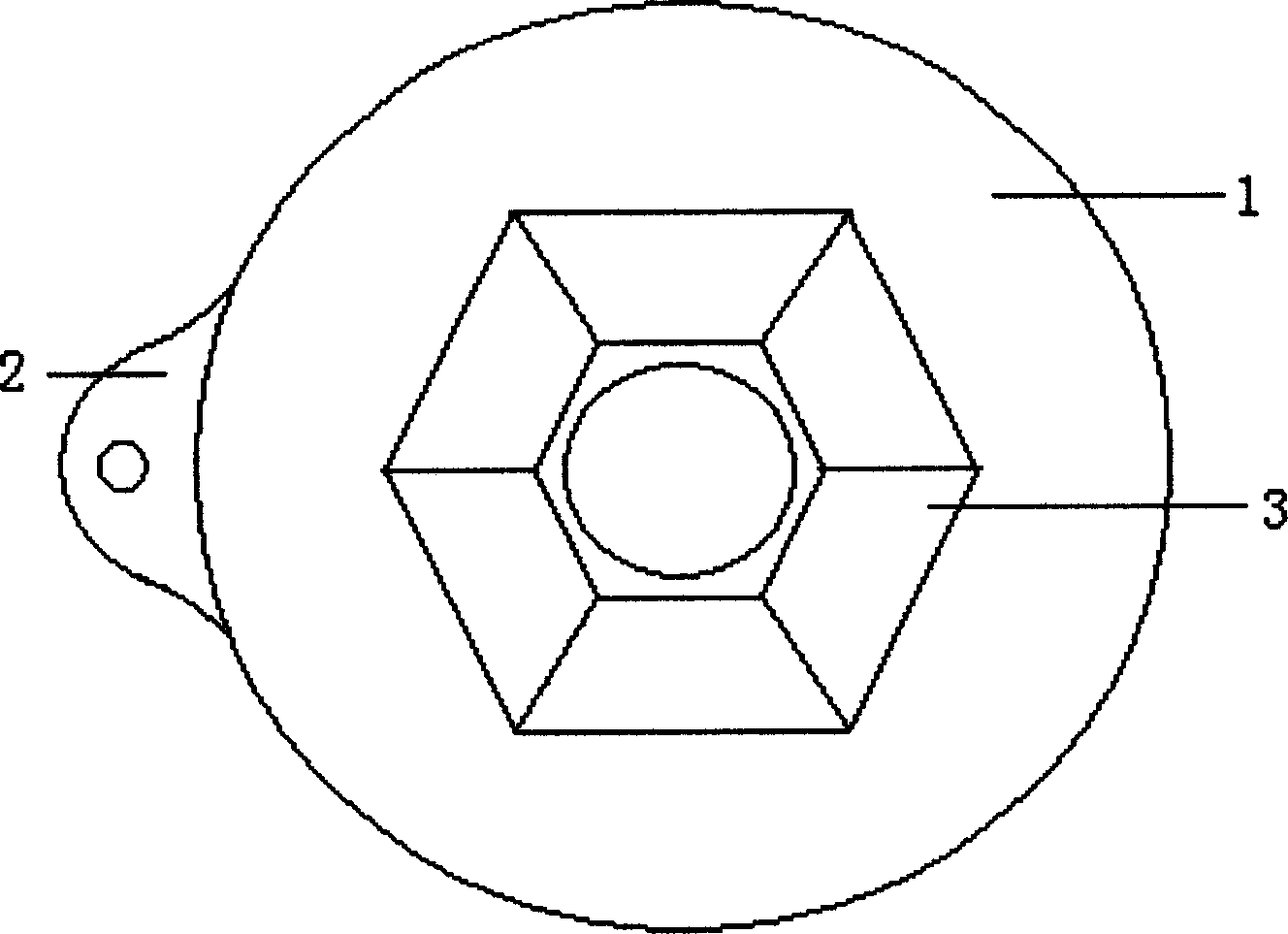

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. see figure 1 , figure 2 As shown, a hexagonal funnel of the present invention comprises a funnel 1 and a handle 2 on the outer edge of the upper mouth, and the outer surface of the funnel 1 from the neck to the mouth is made into a hexagonal shape 3; Funnel 1 and the outside of funnel 1 neck to mouth are made into a hexagonal shape. 3 can be synthesized by one-time plastic injection molding; when using the funnel, hold the handle and insert the lower end of the funnel into the bottle mouth. A gap channel is formed between the hexagon and the mouth of the bottle. When the liquid is poured from the upper mouth of the funnel, the air in the bottle is discharged through the gap channel, so that the air pressure inside the bottle and the outside world are kept in balance, so that the liquid can be easily It can be poured into the bottle to prevent the probl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com