Denture attachment and method for manufacturing the same

A manufacturing method and technology of accessories, applied in fasteners, medical science, dentistry, etc., can solve the problems of low productivity, cumbersome work, difficult to realize automation, etc., and achieve high durability, good corrosion resistance, The effect of high magnetic attraction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

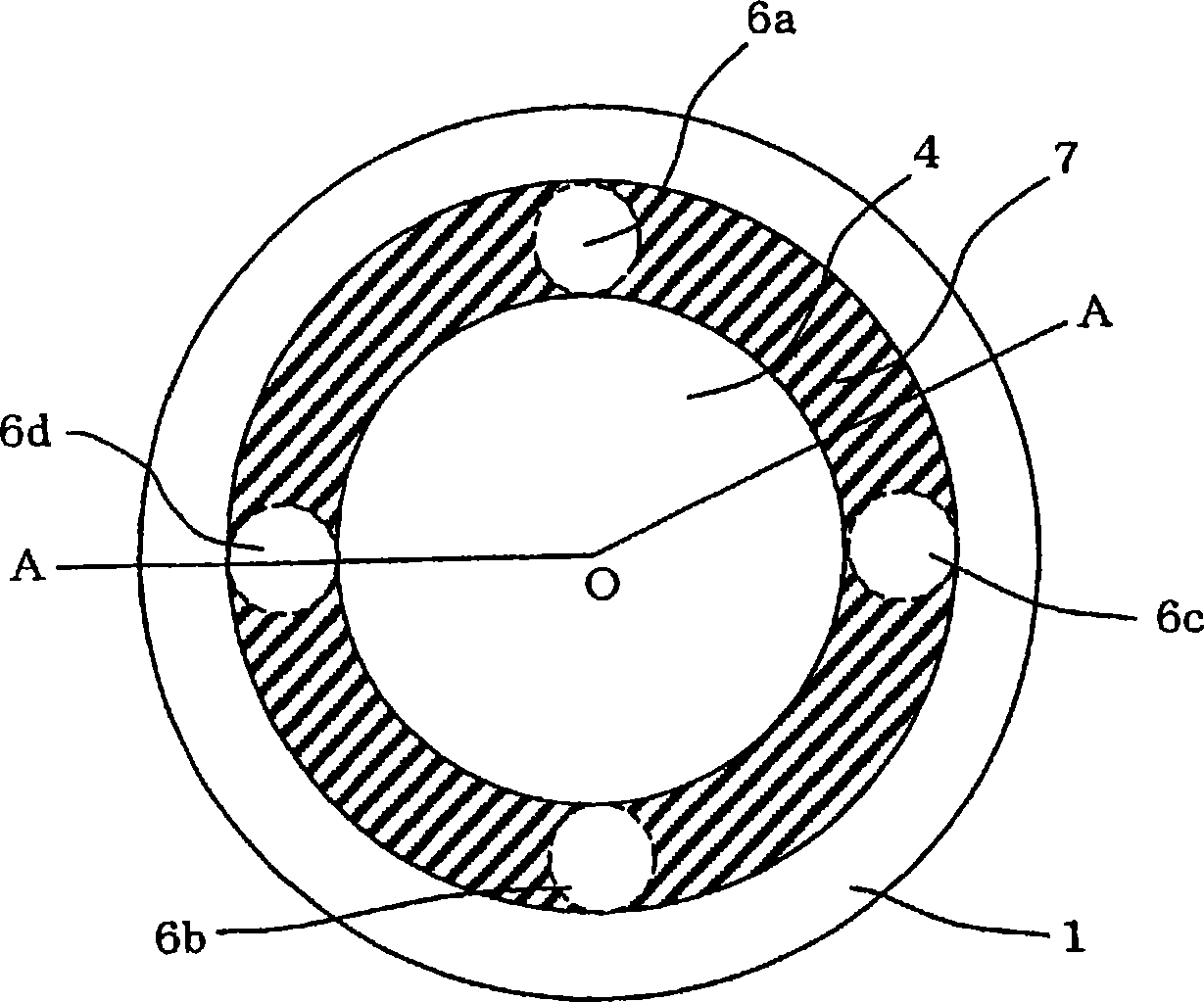

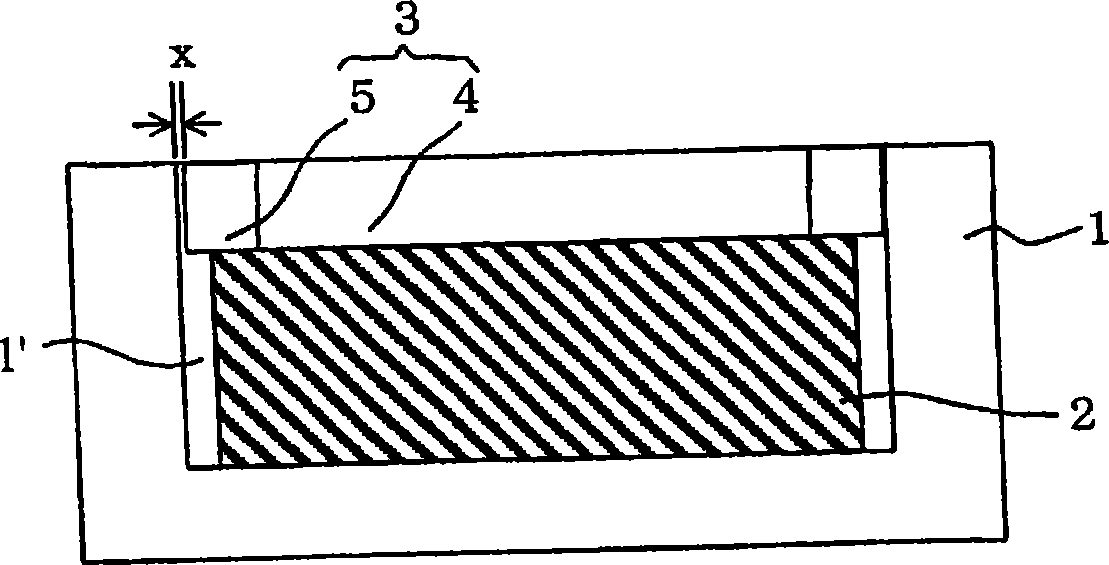

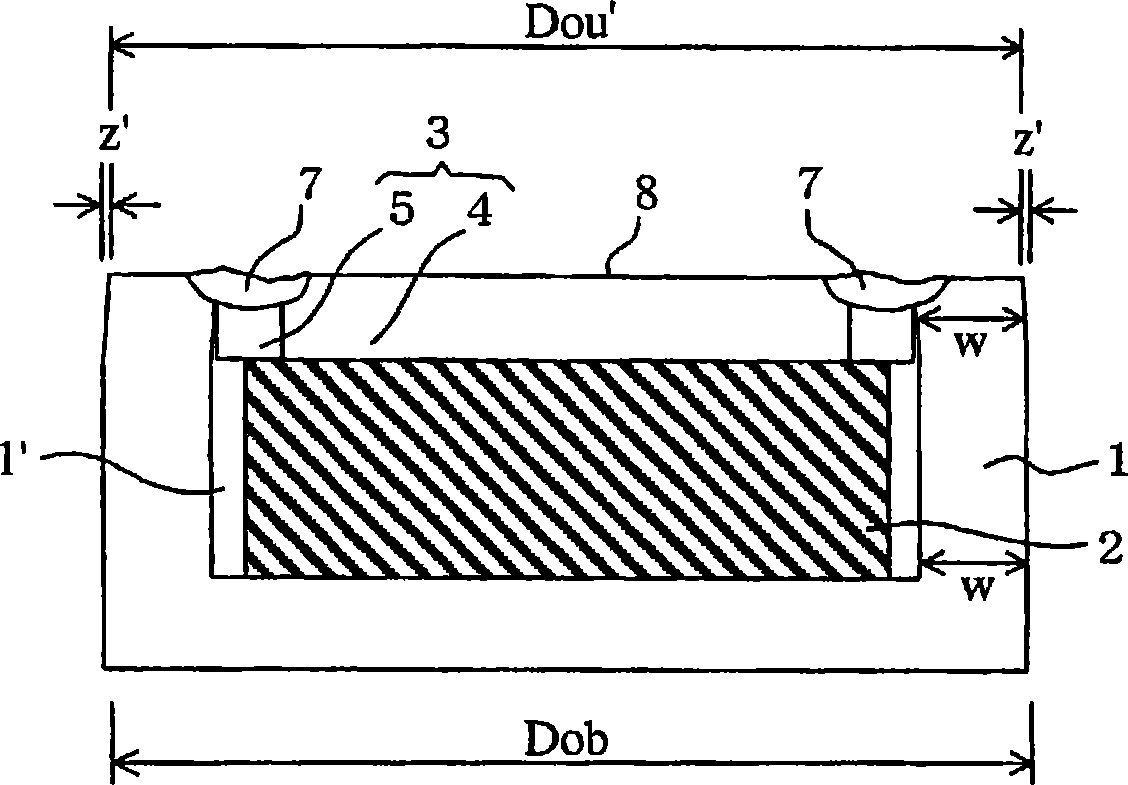

[0087] Cup yokes and seal plates with dimensions shown in Table 1 were used. This sealing plate is a cylindrical material that should be used as a sealing ring embedded in a round rod for a disc-shaped yoke. After drawing, it is cut into slices with a thickness of 0.2mm, and then heat-treated at 800°C in a reducing atmosphere. Then cool to room temperature. The seal plate obtained is obtained by lightly joining the seal ring on the outer periphery of the disc-shaped yoke. Assembled as shown in Figure 1(b), as shown in Table 2, along the circle with a diameter of 2.4mm (with the point O in Figure 1(a) as the center) at the same angular interval of 90°, passing through the 0.5mm spot diameter After the laser spot welding, it was temporarily fixed, and then the whole circumference was welded with a laser with a spot diameter of 0.5 mm along the circumference of the same diameter of 2.4 mm (Fig. 1(c)). As shown in Fig. 3(b), the diameter of the opening of the cup yoke 1 immediat...

Embodiment 2~6

[0091] Use the cup-shaped yoke and the sealing plate of the dimensions shown in Table 1 (the sealing plate is the same as that of Example 1, and the sealing ring is slightly joined to the outer periphery of the disc-shaped yoke), such as Figure 5 As shown in the assembly, as shown in Table 2 to cover the butt joint of cup yoke 21 and seal ring 25, along the circumference of diameter 2.6mm (in Figure 5 The point O of (a) is the center) The first spot welding is performed with a laser having a spot diameter of 0.2mm at the same angular interval of 90°, and the butt joint between the seal ring 25 and the plate-shaped yoke 24 is covered, along the diameter of 2.2mm the circumference of Figure 5Point O in (a) is the center) and the second spot welding is performed at the same angular interval of 90° with a laser having a spot diameter of 0.2 mm to temporarily fix the sealing plate 23 to the cup yoke 21 . Next, along a circle with the same diameter of 2.6 mm as that of the first...

Embodiment 7

[0093] As shown in Table 2, the denture attachment shown in Fig. 6 was produced in the same manner as in Example 2 except that the spot diameters of the laser beams for spot welding and circumferential welding were each set to 0.3 mm, and their characteristics were measured. . The measurement results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com