Newton ring preventing sheet and touch panel using it

A Newton ring and anti-layer technology, which is applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve problems such as glare, and achieve the effect of superior anti-flash and not easy to flash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

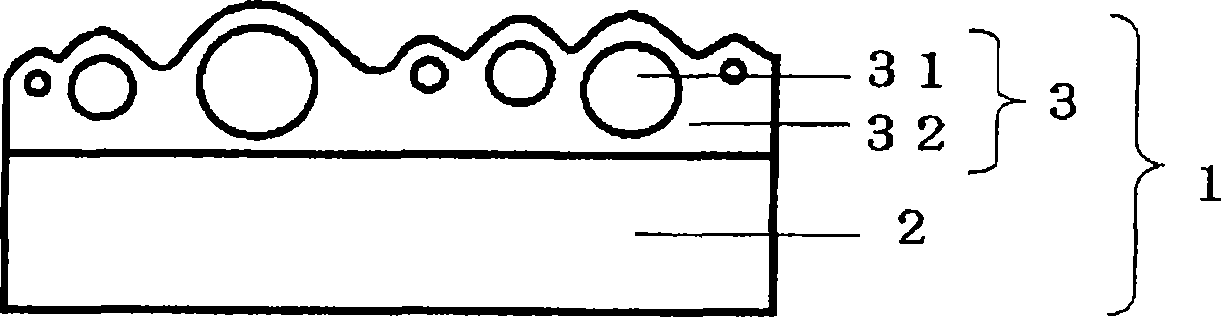

Image

Examples

Embodiment 1

[0108] As a transparent body, on one side of a polyester film (Cosmosiyain A4300: Toyobo Co., Ltd.) with a thickness of 188 μm, the coating liquid for the Newton ring prevention layer of the following formulation was coated, dried, and subjected to ultraviolet light under a high-pressure mercury lamp. Irradiated to form an anti-Newton ring layer with a thickness of 1.5 μm, thereby producing the anti-Newton ring film of Example 1.

[0109]

[0110] ・Ionizing radiation curable organic-inorganic composite resin 100 parts

[0111] (solid content 50%) (inorganic content 38%)

[0112] (デソライト7503: JSR Corporation)

[0113] · Microparticles (acrylic resin particles) 0.2 parts

[0114] (average particle size 2μm) (coefficient of variation 50%)

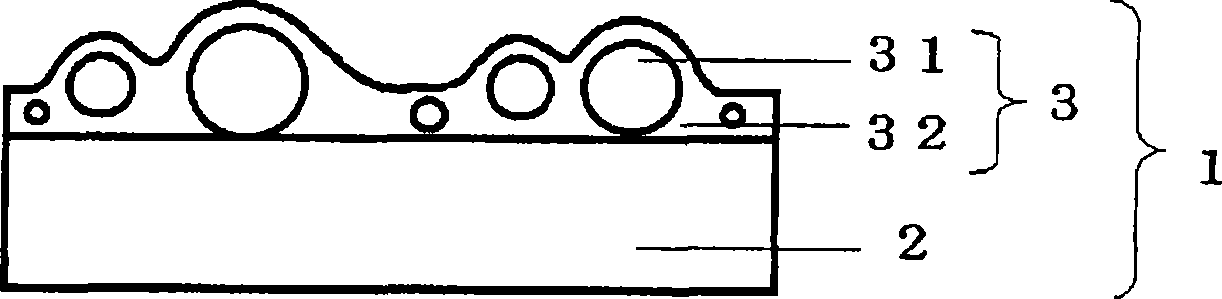

Embodiment 2

[0117] Except that the microparticles of the coating solution for the Newton ring prevention layer in Example 1 are replaced by propylene-based resin particles with an average particle diameter of 2 μm and a coefficient of variation of 33%, other all adopt the same method as in Example 1 to make and implement Example 2 of the Newton ring prevention film.

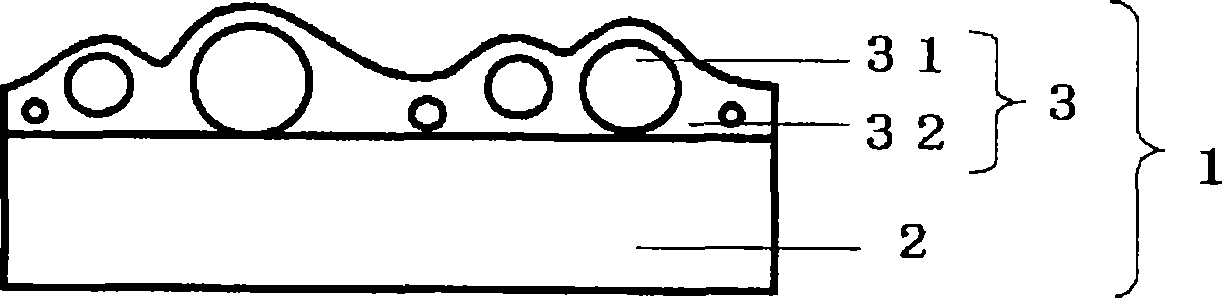

Embodiment 3

[0119] Except that the particles of the coating solution for the Newton-ring prevention layer in Example 1 were replaced with propylene-based resin particles with an average particle diameter of 9 μm and a coefficient of variation of 22%, to make a Newton-ring prevention layer with a thickness of 7 μm, the other In the same manner as in Example 1, the anti-Newton ring film of Example 3 was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com