Deck installation structure of big-span steel bridge

A bridge deck pavement, large-span technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as insufficient service life, increase abrasion resistance, reduce vertical and horizontal horizontal deformation, and reduce cracking dangerous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

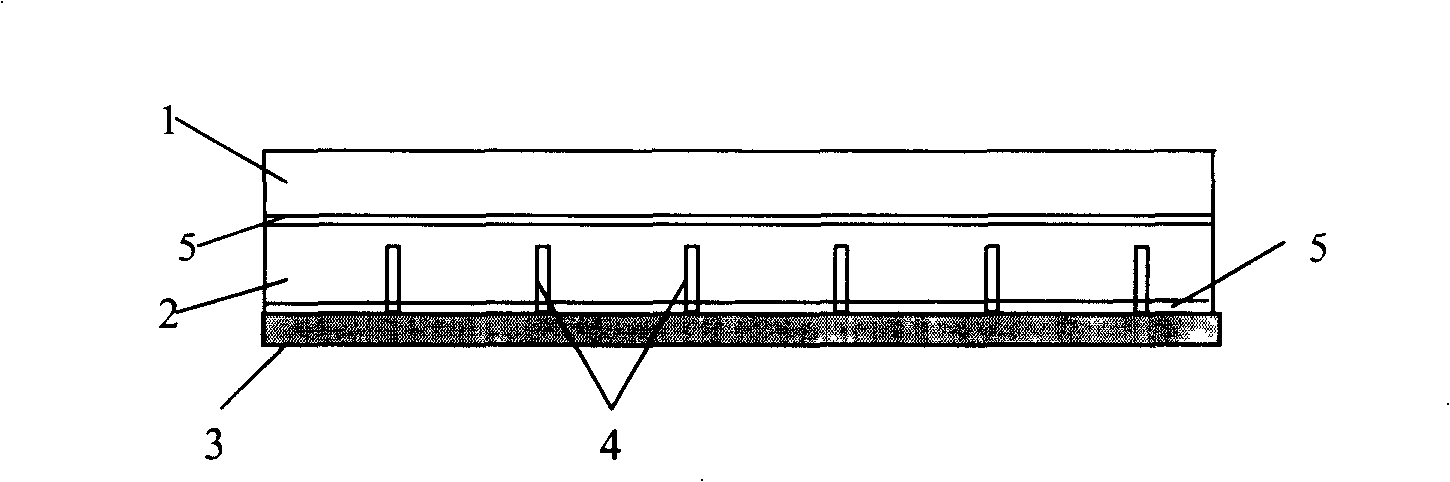

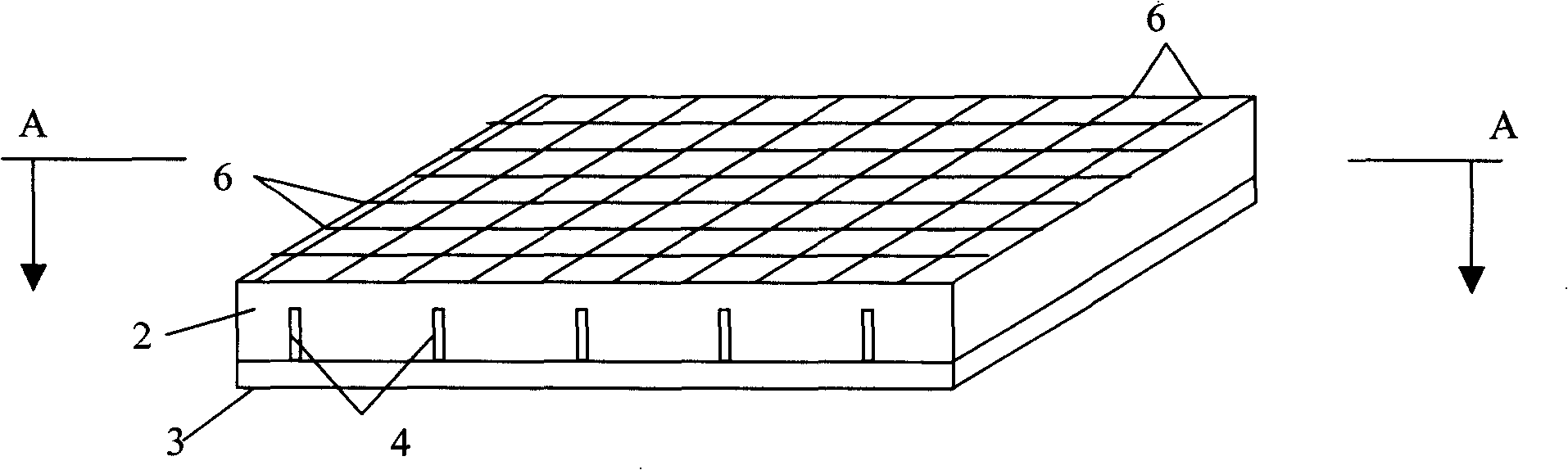

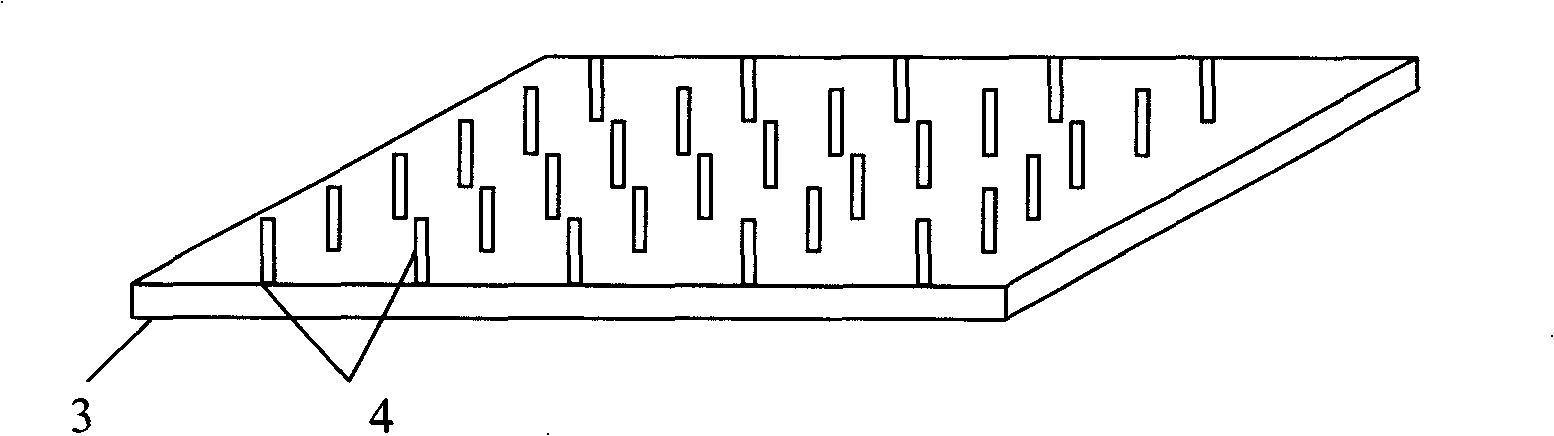

[0027] 1. Use sandblasting to remove oil and rust and thermal spray zinc on the surface of the steel bridge deck 3, and draw lines for the positioning position of the welding stud 4 according to a 30×30cm square.

[0028] 2. Weld the welding studs 4 with a specification of Φ1×5cm on the steel bridge deck 3 with a welding torch at a distance of 30×30cm along the vertical and horizontal directions.

[0029] 3. Spray waterproof adhesive layer 5

[0030] The entire steel bridge deck surface was sprayed with an acrylic-based paint finish in three coats.

[0031]

Cement kg

Finely ground slag powder kg

Light aggregate kg

polymer kg

Mixing water kg

First group

180

350

1050

100

182

Second Group

180

350

1080

80

185

The third group

180

350

1120

60

190

Fourth group

200

350

1110

45

196

fifth group

220

350

1110

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com