Belt conveyer for tunnel furnace for manufacturing solar cell and method for manufacturing the same

A technology of solar cells and manufacturing methods, applied in the directions of furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of non-metallic flint tunnel furnace conveyor belts that cannot withstand high sintering temperature, solar cell pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

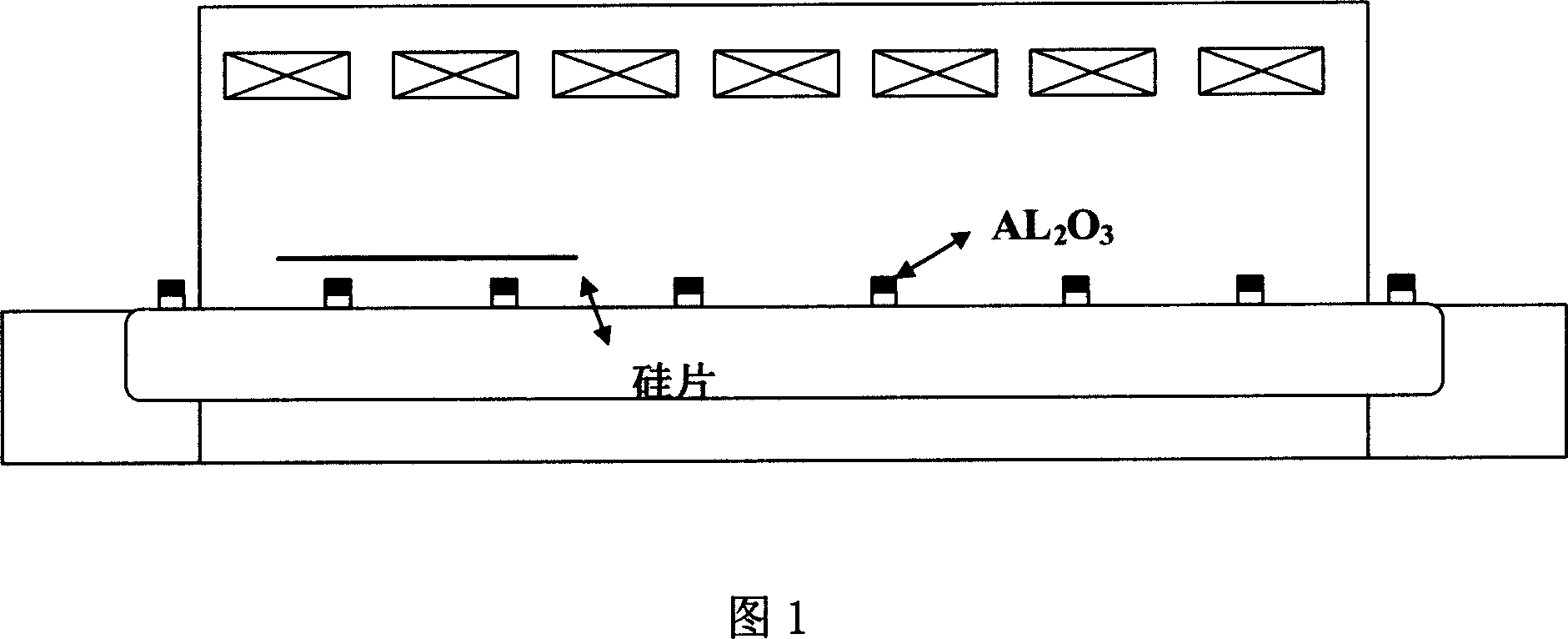

[0017] Fig. 1 is according to an embodiment of the present invention manufactures the sectional view of the flint road furnace that solar cell is used, coating ceramics (Al 2 o 3 )layer.

[0018] Referring to Fig. 1, according to technical scheme of the present invention, provide the flint road furnace conveyer belt that manufactures solar cell, it is made of " nickel-chromium alloy belt ", and a plurality of supporting columns that " nickel-chromium alloy belt " is set on the conveyer belt surface, in The surface of the support column is coated with a ceramic layer (ie Al 2 o 3 layer). Al used 2 o 3 The purity of ceramic powder is 99.99%; the density is 3.98g / cm 3 ; Hardness is 9 (Mohs); Melting point is 2040°C.

Embodiment 2

[0020] According to another technical scheme of the present invention, provide the manufacture method of the flint furnace conveyer belt that manufactures solar cell, comprise following process step:

[0021] Step 1. Stamping "nickel-chromium alloy strip" to form a plurality of support columns protruding upwards on its front side;

[0022] In step 2, the top surfaces of multiple support columns are coated with a ceramic layer using plasma micro-arc ceramic layer technology. With a purity of 99.99% and a density of 3.98g / cm 3 , hardness of 9 (Mohs), melting point of 2040 ° C ceramic powder as raw material.

[0023] "Nichrome strip" processed through steps 1 and 2 to melt the bonding material to Al 2 o 3 powder and "Nichrome Ribbon", the Al 2 o 3 Powder and " nickel-chromium alloy belt " are bonded together, constitute the flint road furnace conveyor belt of the present invention.

[0024] The above has described the flint furnace conveyor belt for manufacturing solar cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap