Inductive load control device

A load control and inductive technology, applied in the control system, DC motor speed/torque control, electrical components, etc., can solve the problems of difficult cost control, excessive instantaneous current increase, inability to maintain long-term operation and component life, etc., to achieve Avoid the influence of switching sparks, increase the life and reliability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

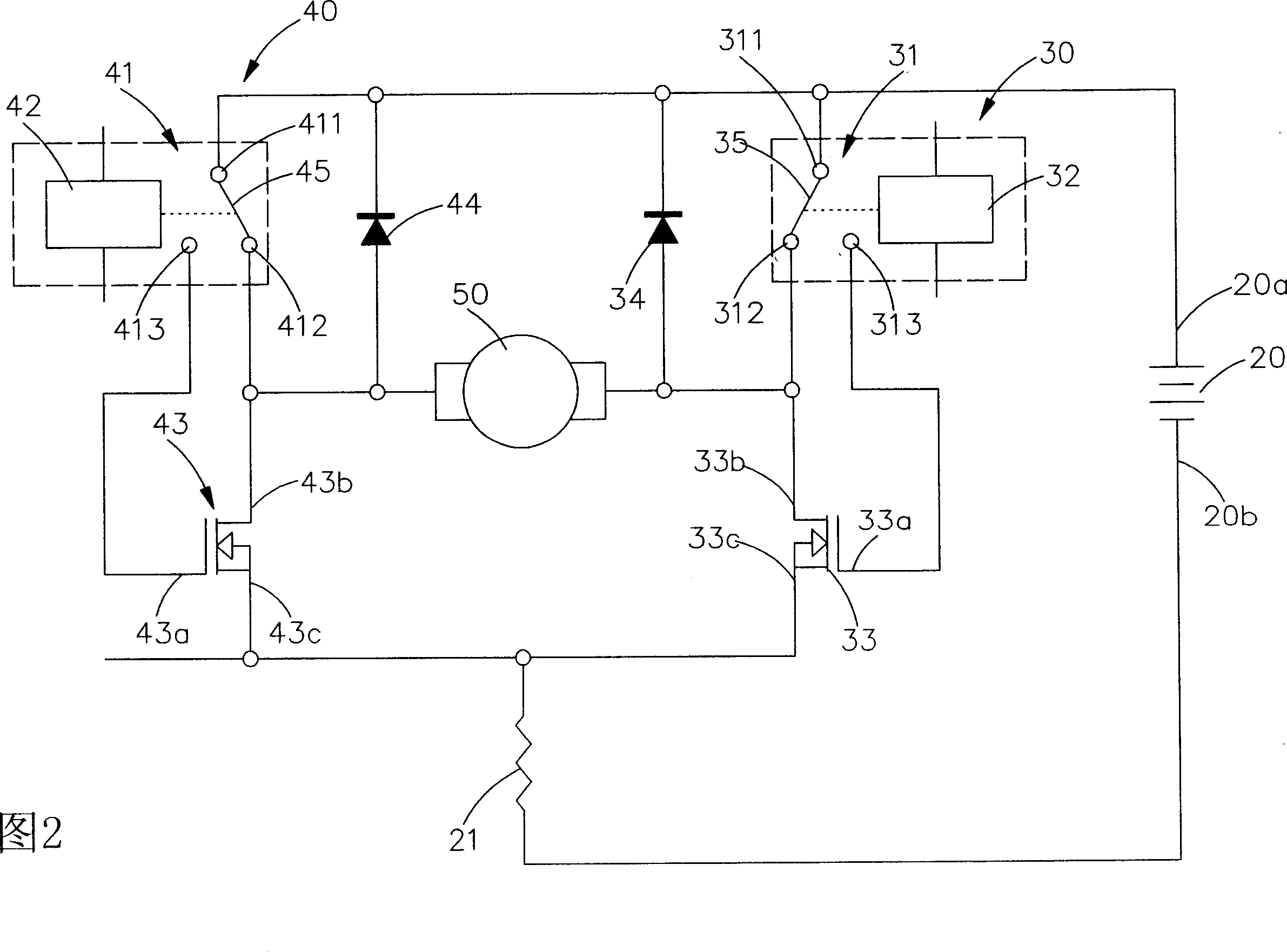

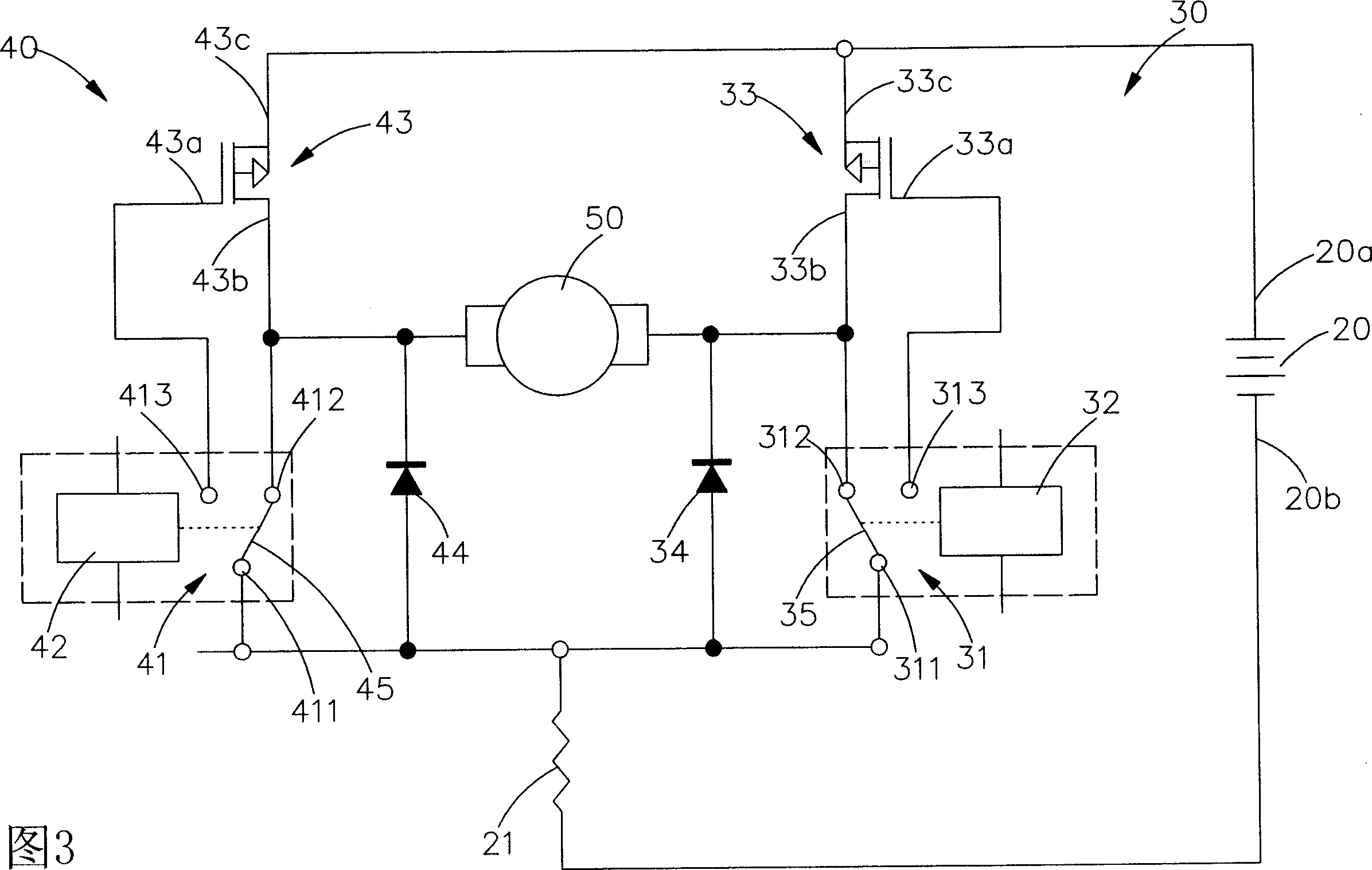

[0061] The first embodiment of the inductive load control device of the present invention uses an N-type field effect crystal (N-MOSFET). The schematic diagram is shown in FIG. Control group 40 and a second inductive load 50 (see FIG. 2); wherein:

[0062] The power supply 20, assembled in a circuit, has a positive terminal 20a and a negative terminal 20b;

[0063] The resistor 21 is used to detect the current, and it is connected in series with the negative terminal 20b of the power supply 20;

[0064] The first control group 30 is connected in series between the positive terminal 20a of the power supply 20 and the resistor 21. The first control group 30 includes a third relay switch 31, a third relay 32, a second field Effect crystal 33 and a first diode 34 combined, the second field effect crystal 33 is an N-type field effect crystal, the third relay switch 31 cooperates with a first reed 35 with a third common contact 311 A third normally closed contact 312 and a third n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com