Liquefied natural gas storage tank

A storage tank and fluid technology, applied in fixed capacity gas storage tanks, gas processing/storage purposes, gas/liquid distribution and storage, etc., can solve the problems of expensive, expensive, and too expensive construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

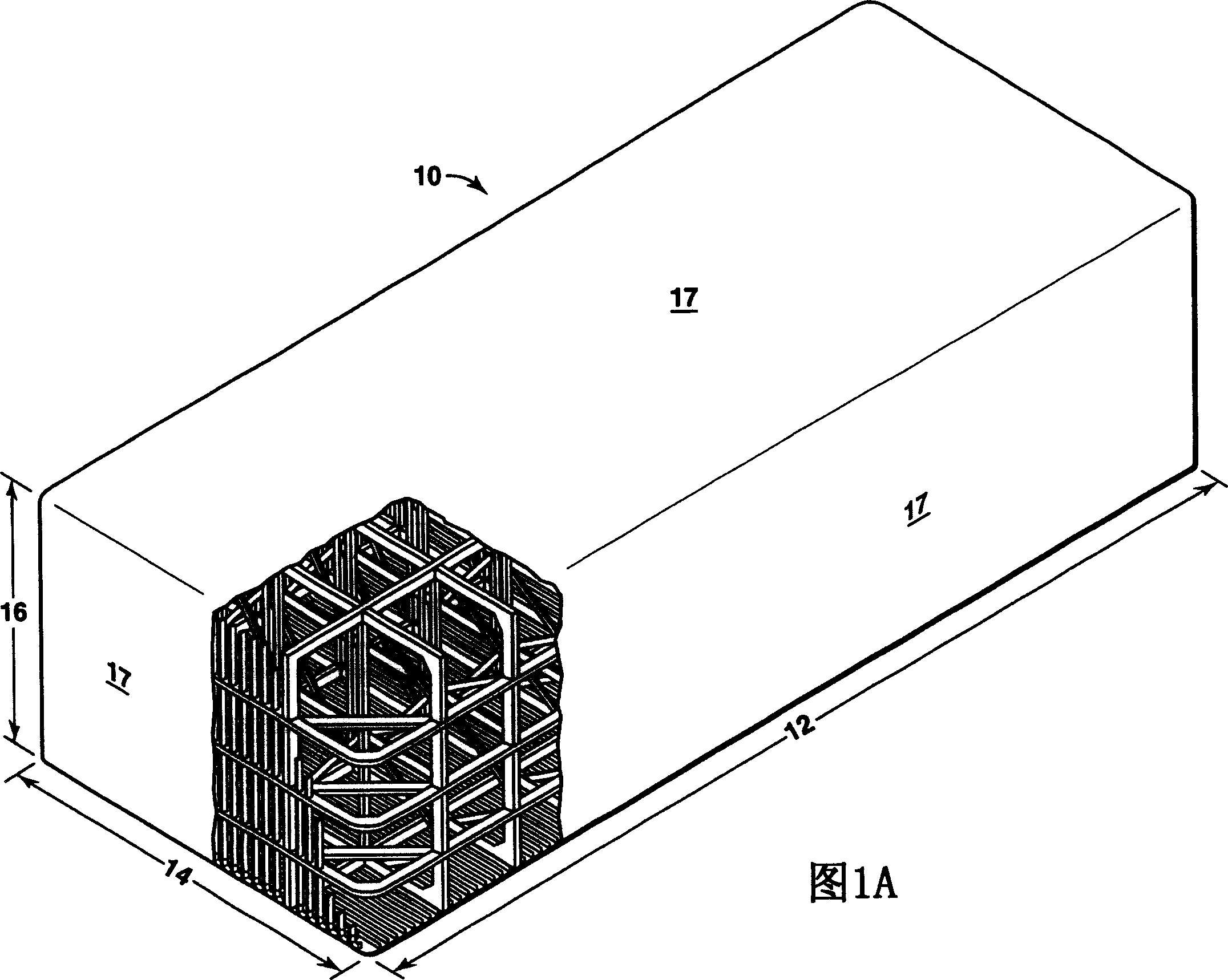

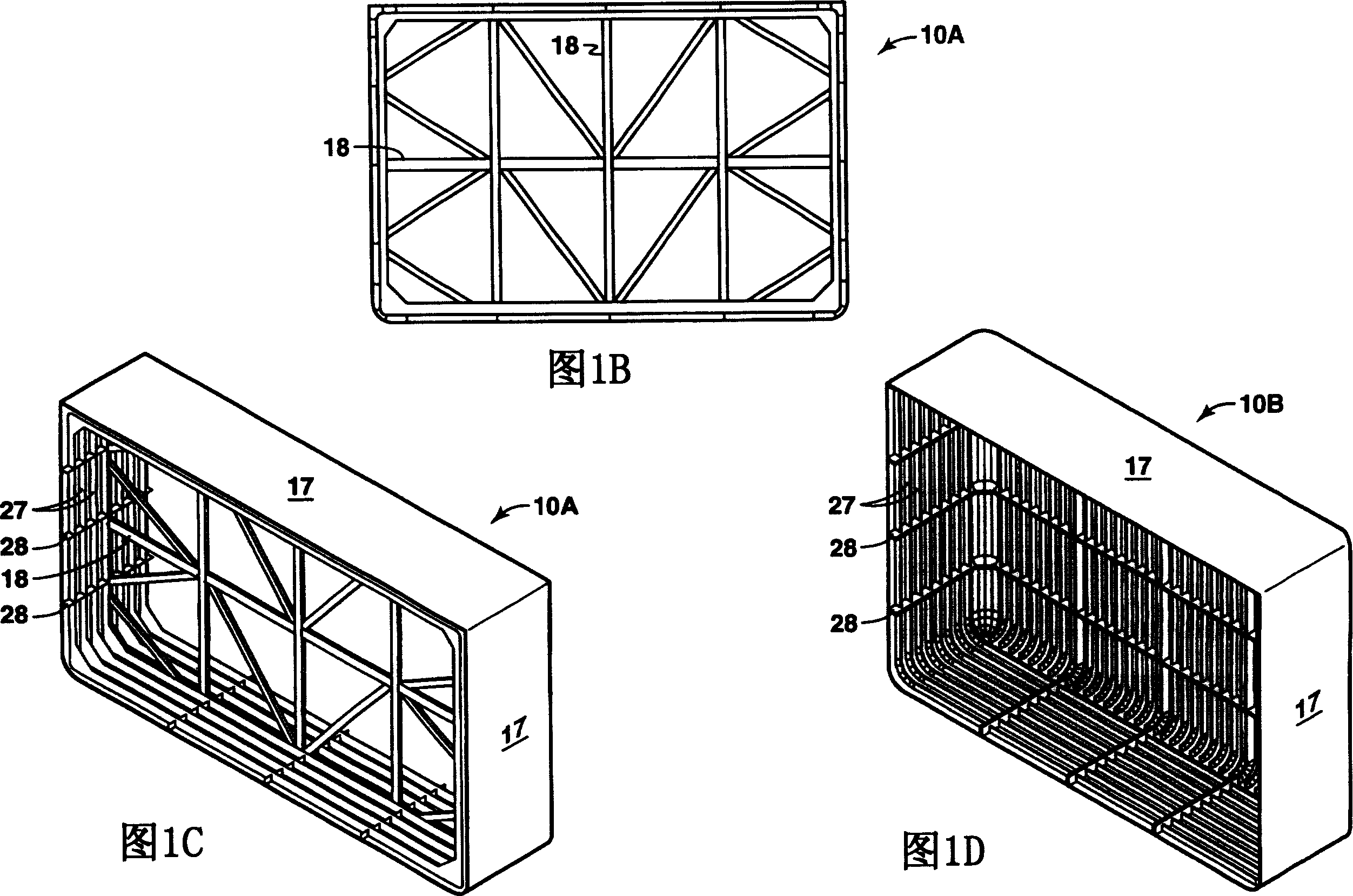

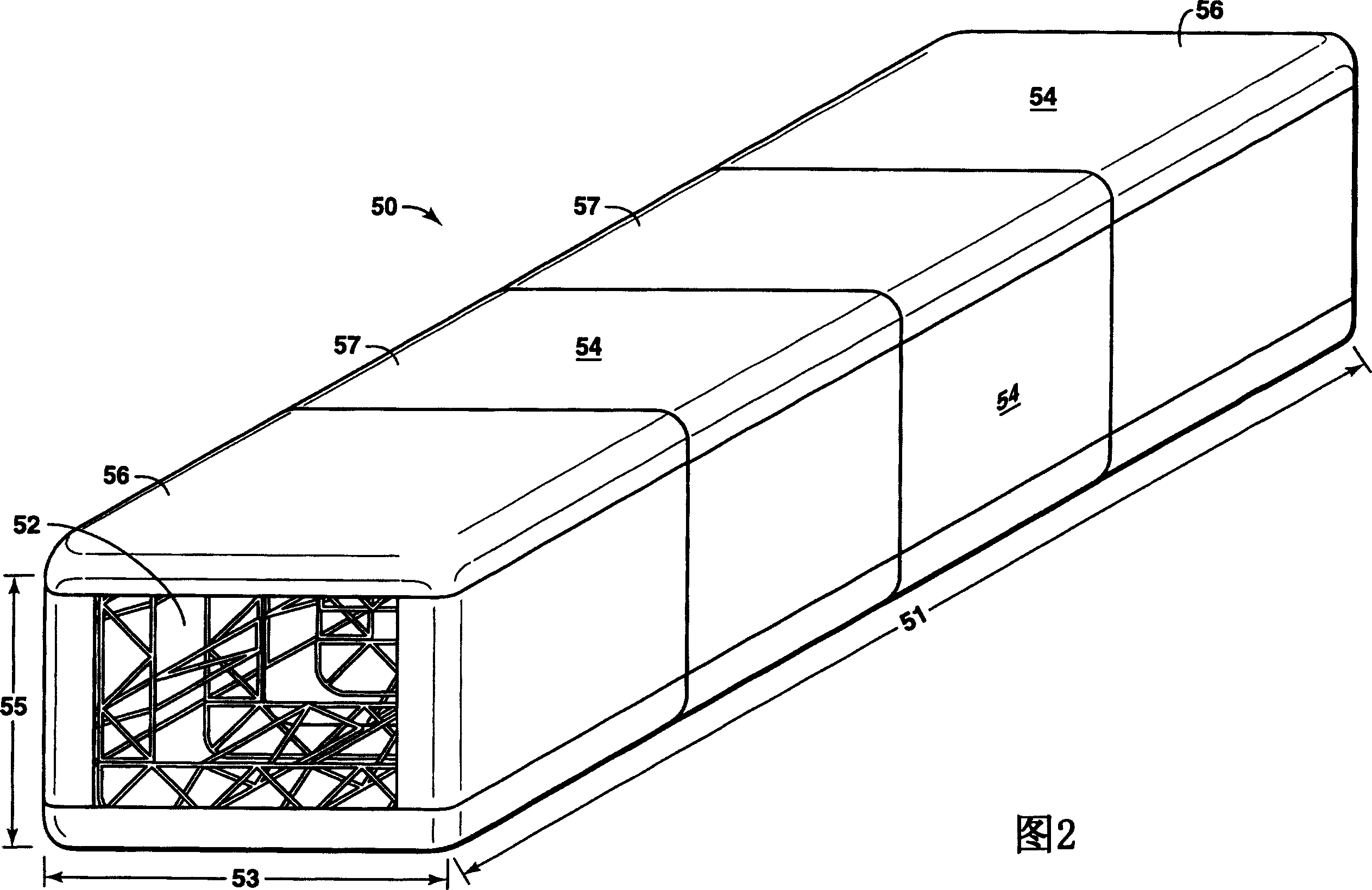

[0044] [0043] The substantially rectangular storage tank of a preferred embodiment of the present invention is designed to provide the ability to change the volume of the tank in discrete steps without requiring substantial redesign of the tank. For constructional purposes only, this is achieved by considering the tank as comprising a plurality of similar structural modules. For example, a 100,000 cubic meter tank may be considered to comprise four substantially equal structural modules by dividing a large tank in three imaginary vertical planes suitably spaced along its length such that each section is conceptually capable of holding approximately 25,000 cubic meters of liquid to achieve. Such tanks consist of two substantially identical end sections and two substantially identical middle sections. By removing or adding the middle part in discrete steps during the construction of the tank, it is possible to obtain tanks with the same cross-section, ie the same height and wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com