Multifunctional feeding plate

A multi-functional, chassis technology, applied in the field of appliances, can solve the problems of high labor intensity, time-consuming and labor-intensive, poor interchangeability of feeding trays, etc., and achieve the effect of convenient operation, ingenious conception and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

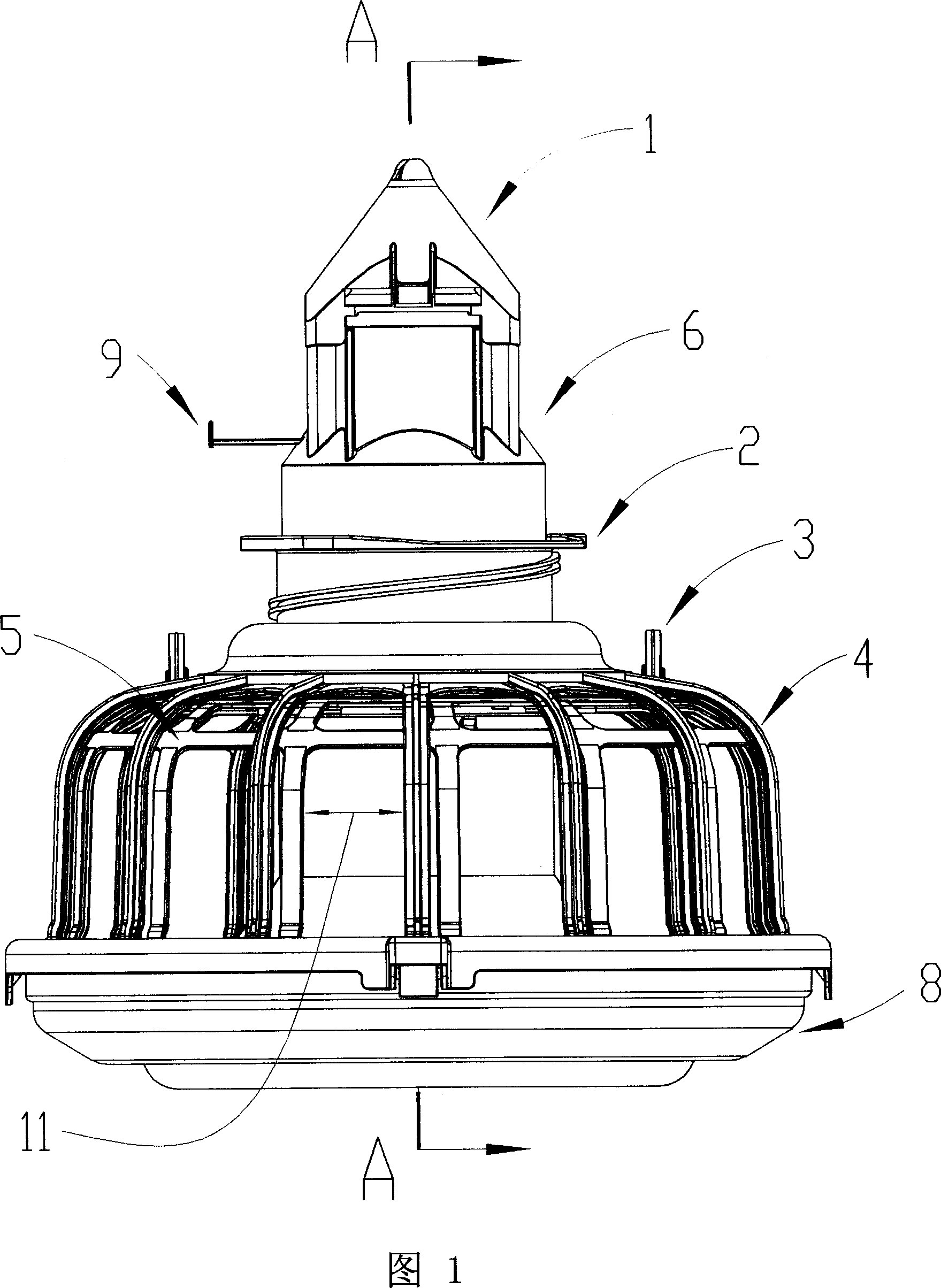

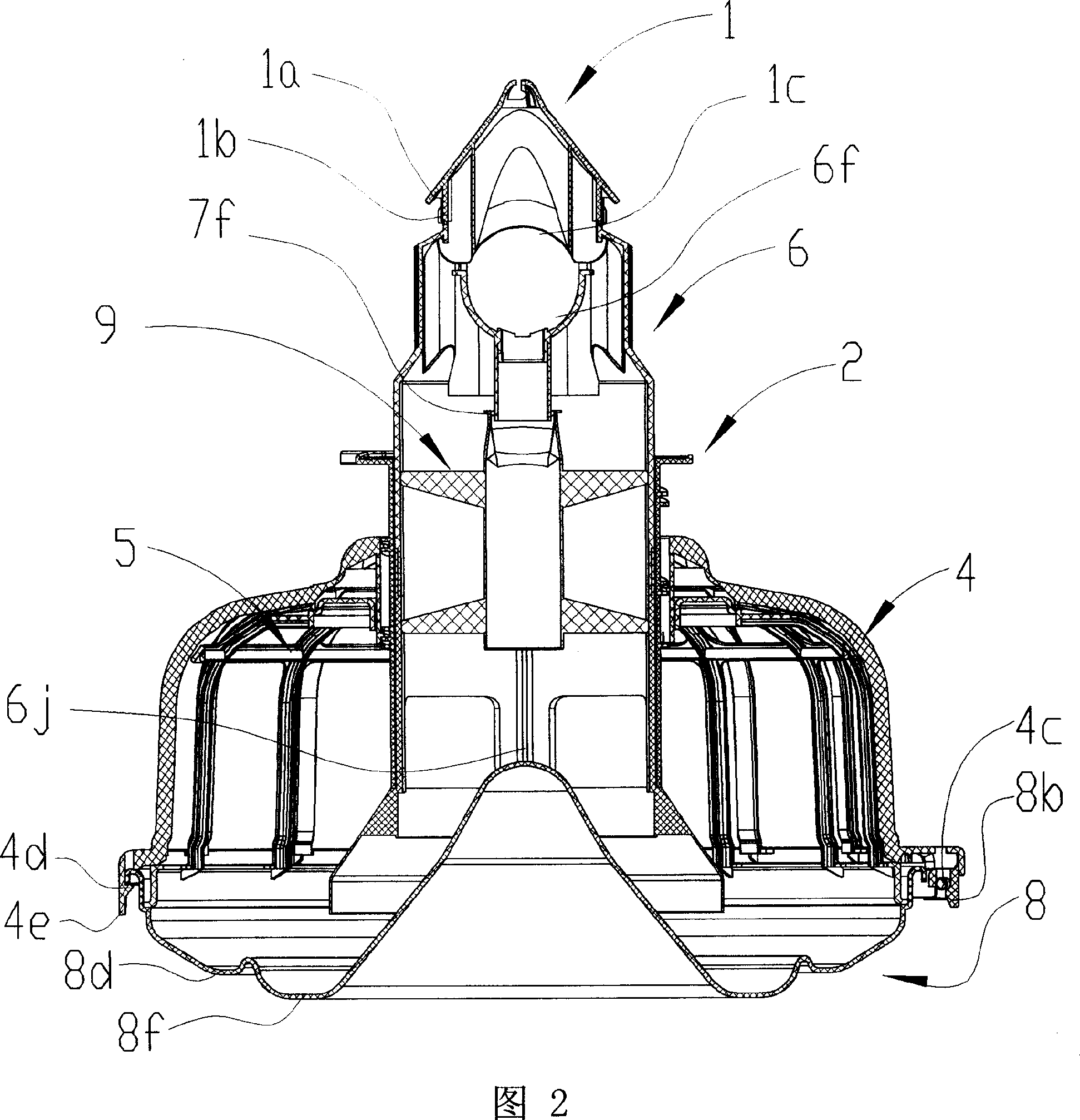

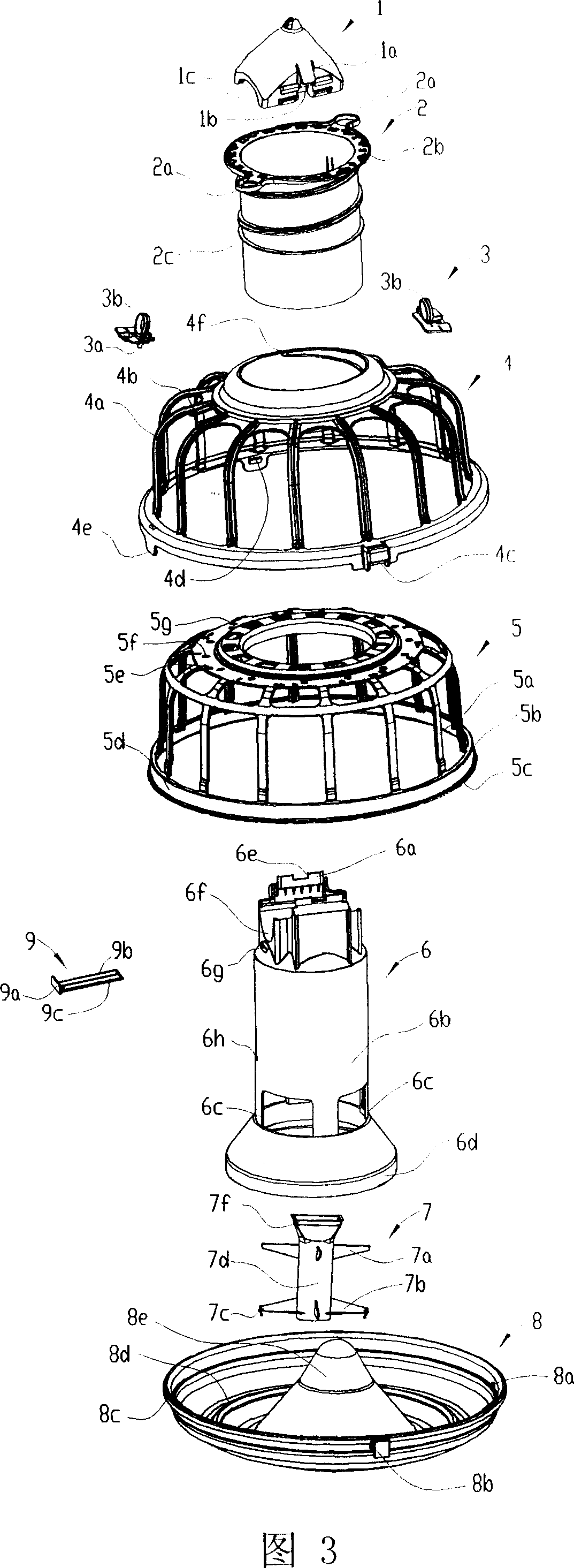

[0036] As shown in Figure 3, the feeding tray of the present invention is mainly composed of a hanging cap 1, an adjustment sleeve 2, a positioning plate 3, a fixed fence 4, a movable fence 5, a hanger 6, a material reducing pipe 7, a chassis 8 and a baffle 9 composition, as shown in Fig. 1 and Fig. 2, this feeding plate forms a cylindrical hole after the semicircular arc 6f on the hanger 6 and the semicircular arc 1c on the hanging cap 1 cooperate, and the inner diameter of the cylindrical hole is the same as that of the material tube Fit the outer diameter of the feed tube and fix it on the feed tube. The feed tube is opened downward to facilitate the drop of feed, as shown in Figure 15, Figure 16, Figure 17 and Figure 18. There are special feed openings on both sides of the feed The locating pawls of the hanger 6 cooperate with the two locating holes 6k on the hanger 6, so that the feeding dish is fixed on the feed pipe. The assembly between the hanger 6 and the hanging cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com