Wet-type cleaning device

A cleaning device, wet technology, applied in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problem of complex fixing methods of liquid supply barrels, and achieve the effect of simplifying the fixing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

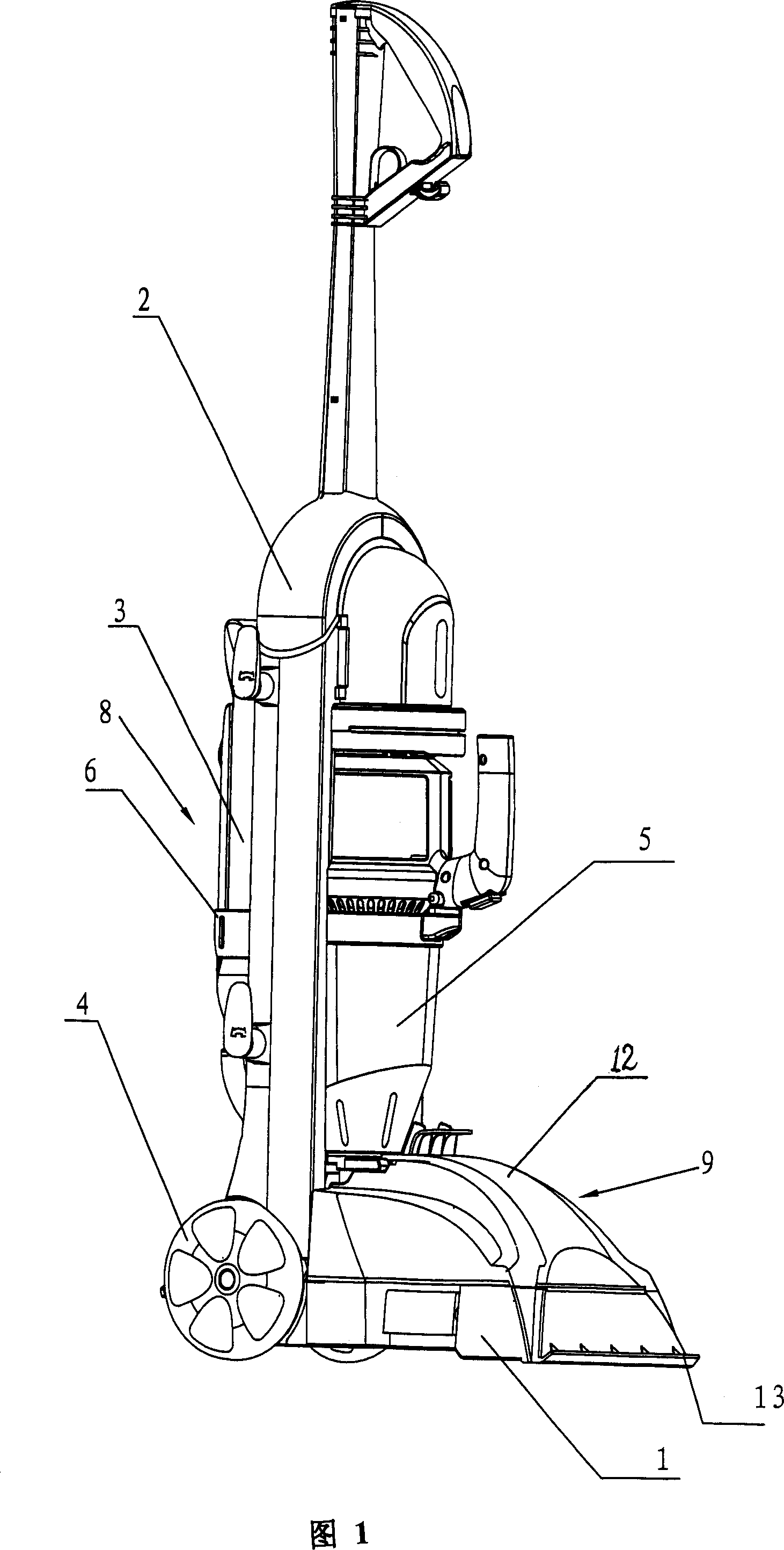

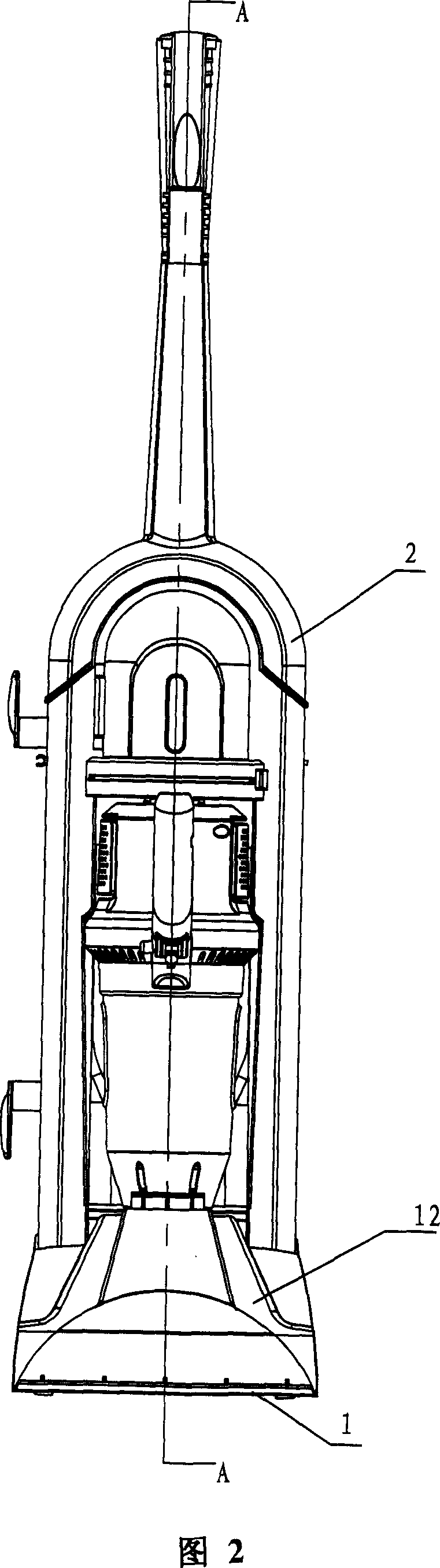

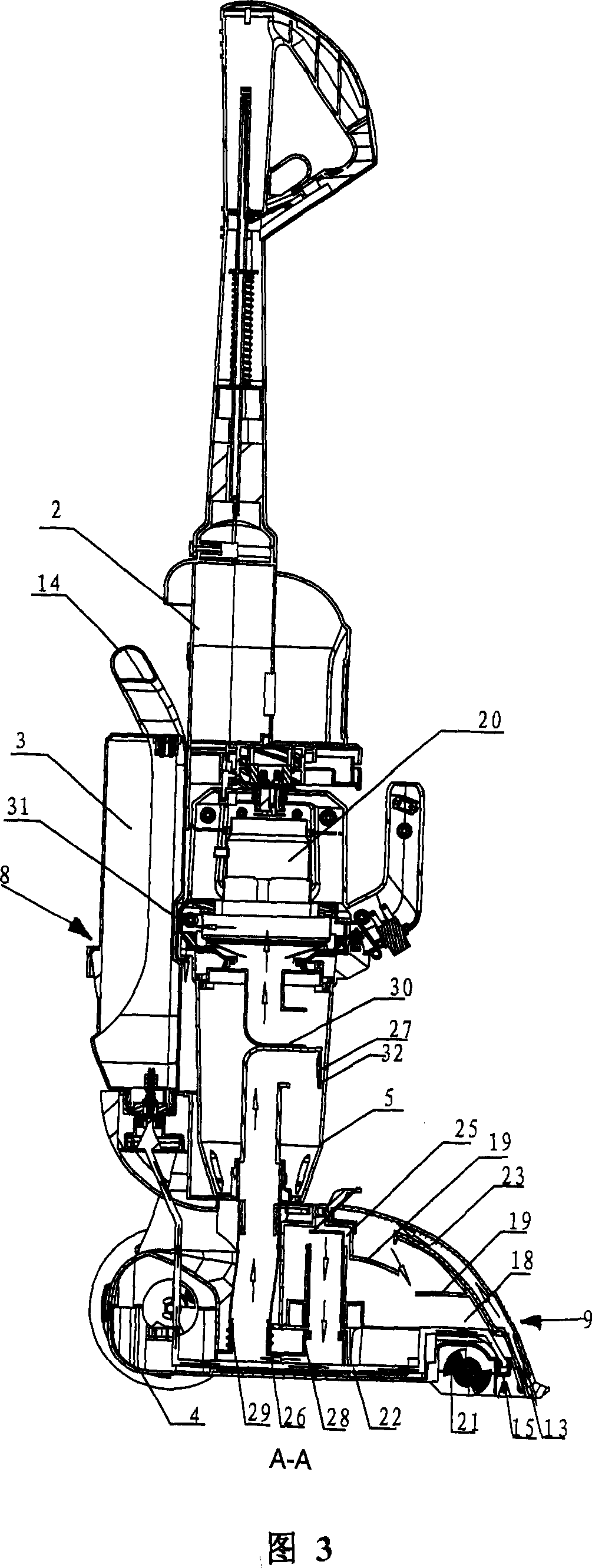

[0018] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The wet cleaning device as shown in accompanying drawing 1, accompanying drawing 3, accompanying drawing 4, comprises the base 1 that is suitable for moving on the surface to be cleaned; The upright handle 2 that is connected with described base 1 phase axis; At least partly set The liquid distribution mechanism 8 on the base 1 and the upright handle 2; the liquid recovery mechanism 9 arranged on the base 1; the upper recovery bucket 5 arranged on the upright handle; and the vacuum source 20 arranged on the top of the upright handle 2 . Among them, the liquid distribution mechanism 8 is used to spray some cleaning liquid on the surface of the object to be cleaned, and the liquid recovery mechanism 9 sucks the dust on the surface of the object together with the residual cleaning liquid into the cleaning device under the suction of the vacuum s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com