Self-loading and self-compression garbage truck

A technology for garbage trucks and dump trucks, which is applied in the direction of garbage storage, presses, transportation and packaging, etc., and can solve the problems of garbage accumulation, high cost of use, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

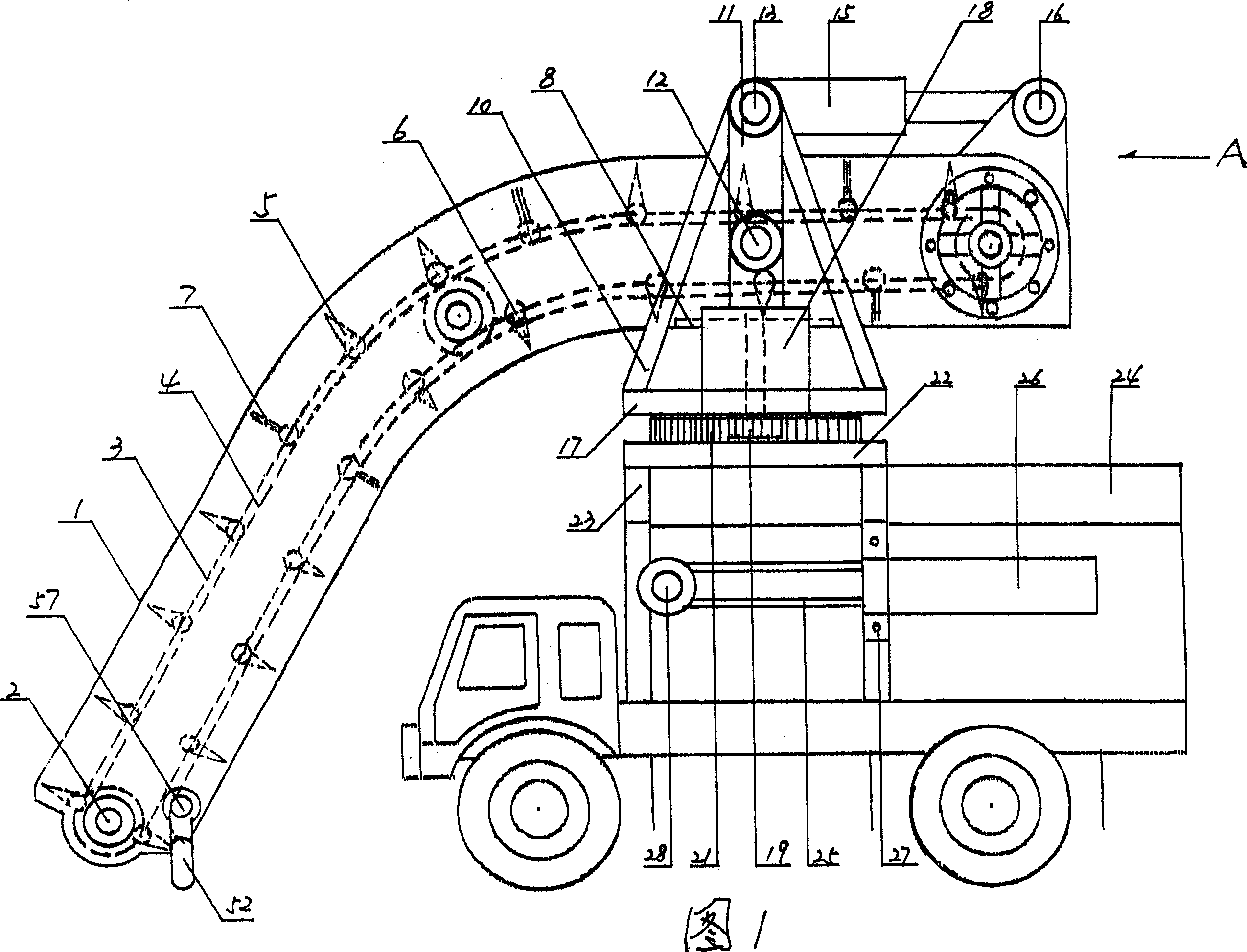

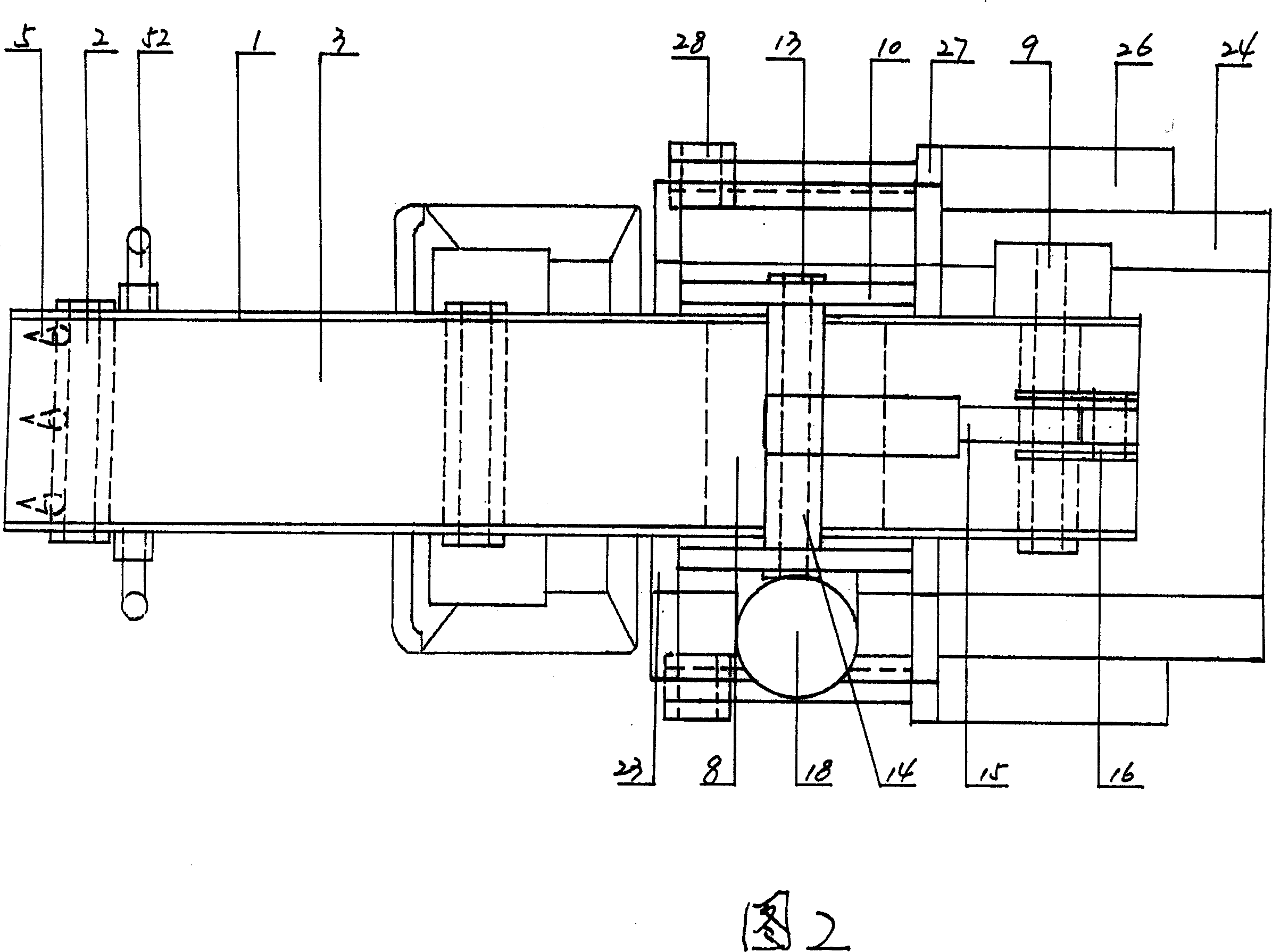

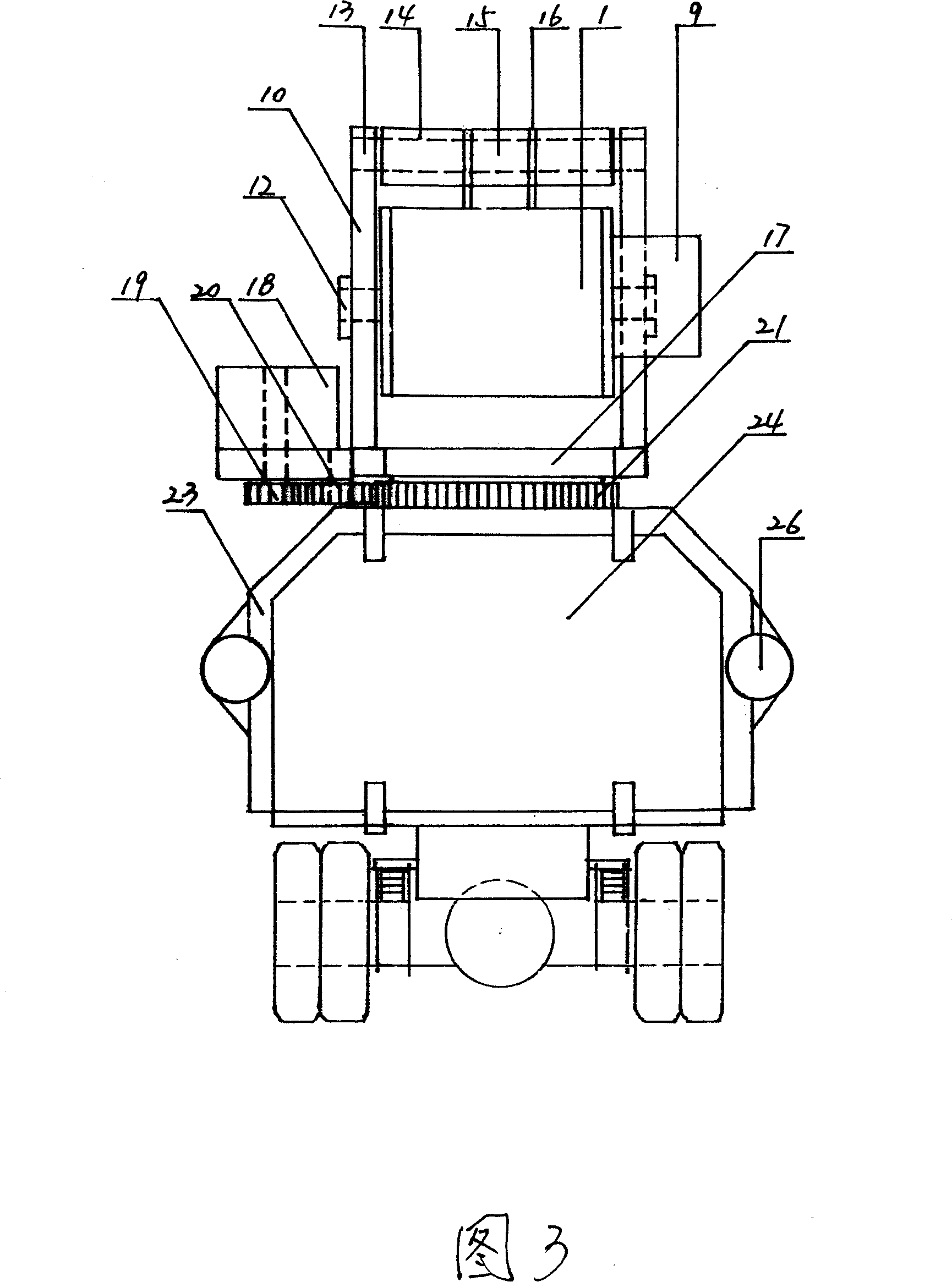

[0035] As shown in Figures 1, 2, and 3, the garbage truck is refitted with a dump truck chassis with a tipping bucket. The whole vehicle is mainly composed of a loading system, a compression system and a rotating device.

[0036] First, refit the dump truck box 24, remove the front box board and the gantry frame of the truck box, so that its shape can be adapted to the requirements shown in Figures 1, 2, and 3. In the middle, two horizontal shaft grooves 25 are provided, and the four walls and the rear door of the carriage are reinforced so that it can reach the strength requirement of compressing garbage.

[0037] The loading system is shown in Figures 4 and 5. The loading arm 1 is a square elbow structure. At least two belt pulleys 2 are respectively installed in the shaft holes at both ends of the loading arm 1. There are two roller slideways 4 on each side. Be respectively installed on the sidewalls on both sides of the square tube for the purpose of sliding the belt rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com