Round-head keyhole sartorius

A sewing machine and round head technology, which is applied in the field of round head buttonhole sewing machines, can solve the problems of not being able to change jobs easily, and spending a lot of time and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

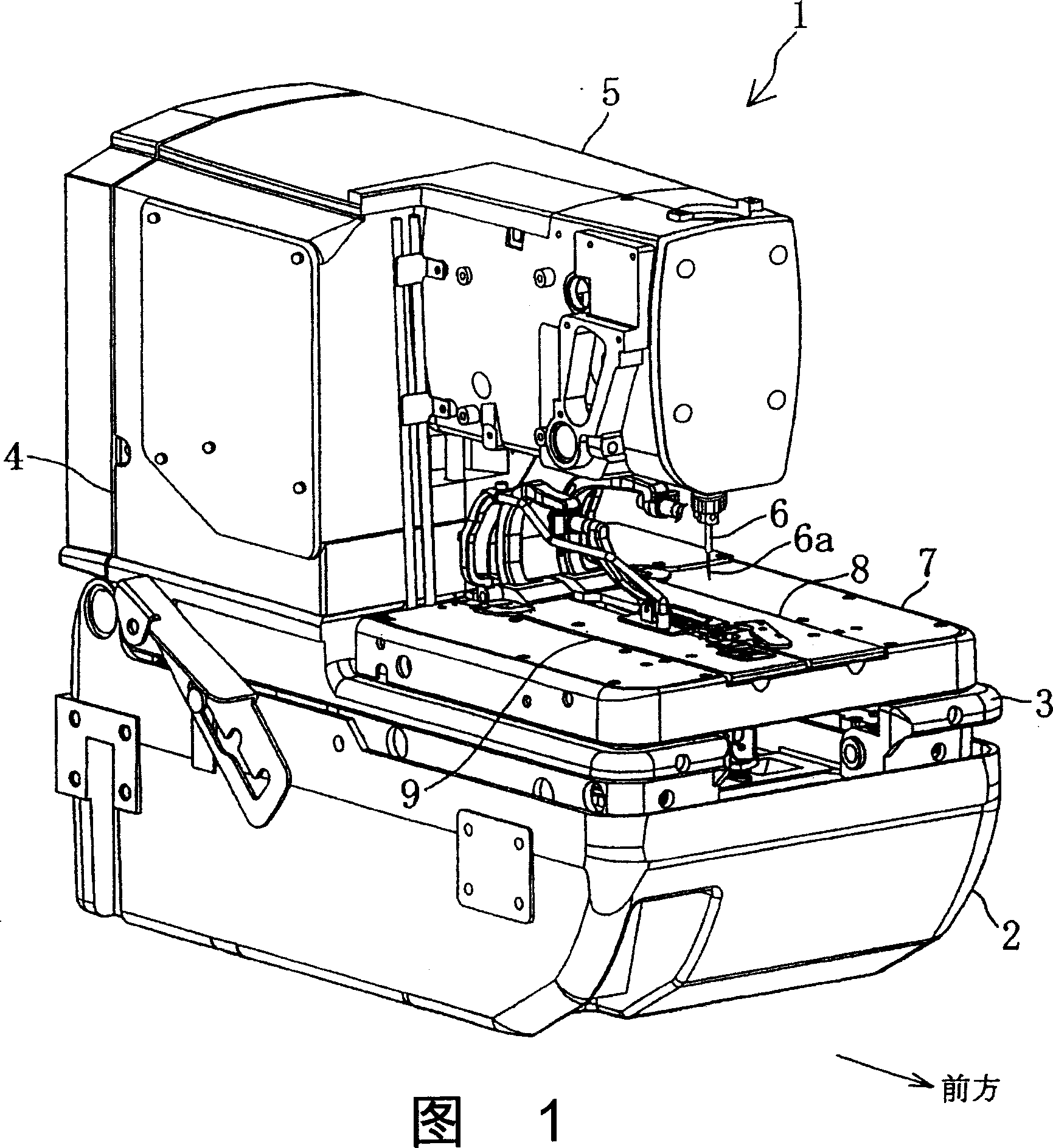

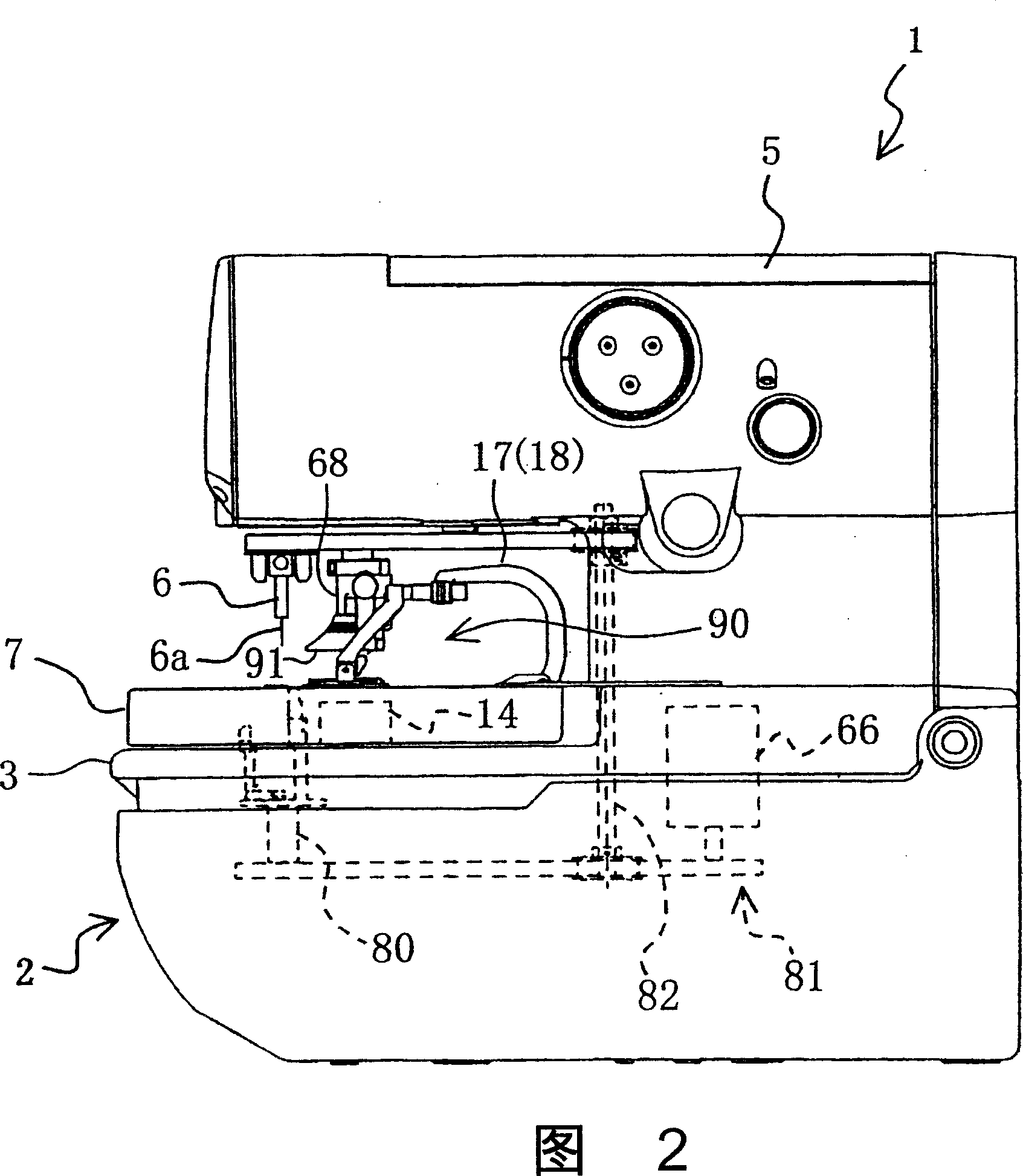

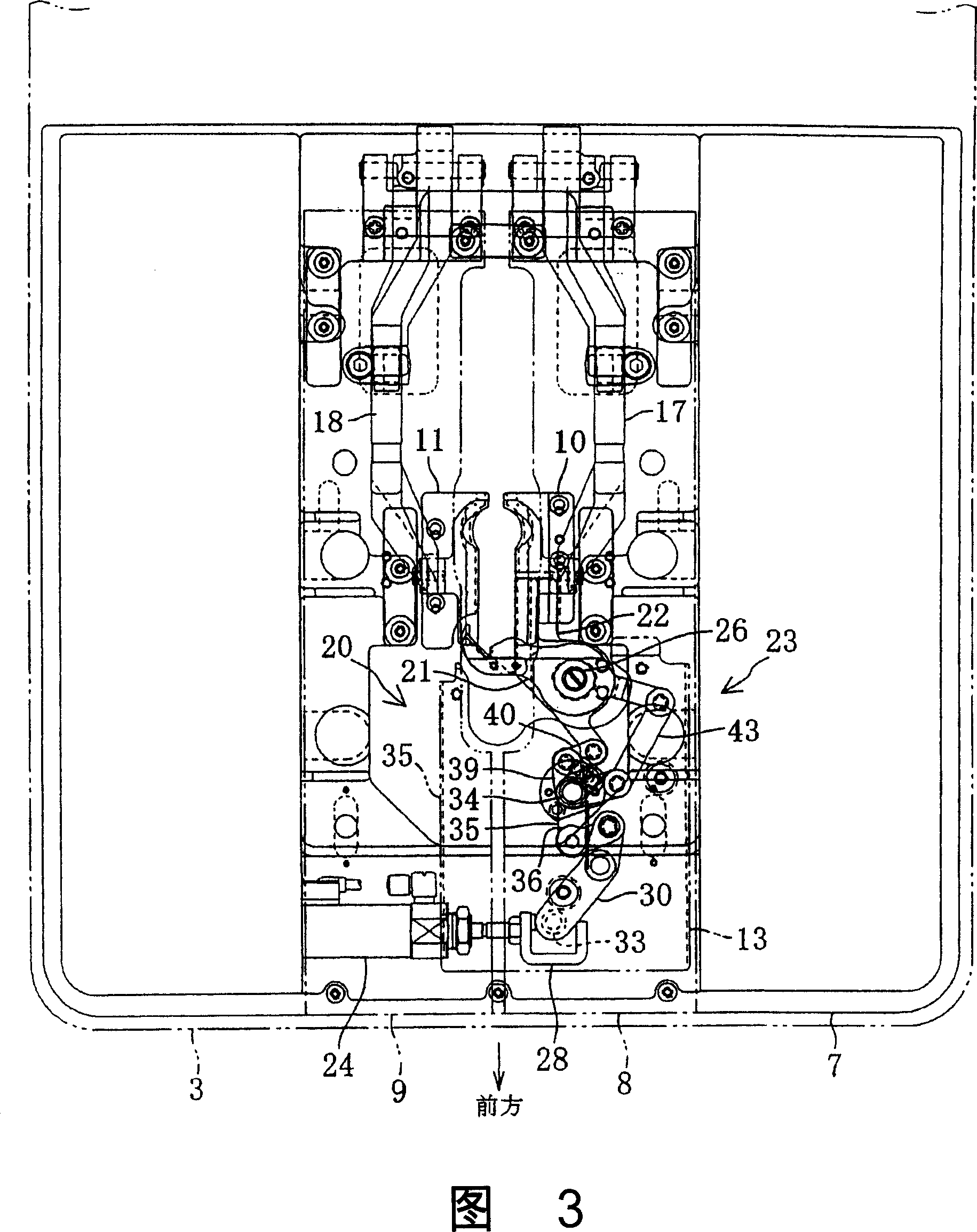

[0033] Embodiments of the present invention will be described with reference to the drawings. This embodiment is an example in which the present invention is applied to, for example, a buttonhole sewing machine 1 for sewing buttonhole stitches HN (see FIG. 4 ) having a knot shape on denim (denim). The eyelet keyhole stitch HN is composed of the eyelet head HM and the tail portion HK linearly extending from the eyelet head HM.

[0034] As shown in Fig. 1, the eyelet buttonhole sewing machine 1 comprises: a substantially rectangular box-shaped machine base 2 with an open top; a bottom plate portion 3 embedded in the machine base 2; the column part 4; and the casing part 5 extending forward from the upper part of the column part 4. The buttonhole sewing machine 1 is fixed on a sewing machine bed (not shown).

[0035] A needle bar 6 to which a sewing needle 6a is mounted is provided at a lower portion on the front end side of the casing portion 5 so as to be movable up and down....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap