Roll forming machine

A forming machine and rolling technology, which is applied to forming tools, metal rolling stands, metal rolling mill stands, etc., can solve the problems of large-scale and high cost, and achieve the effects of simple replacement operation, simplified structure and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

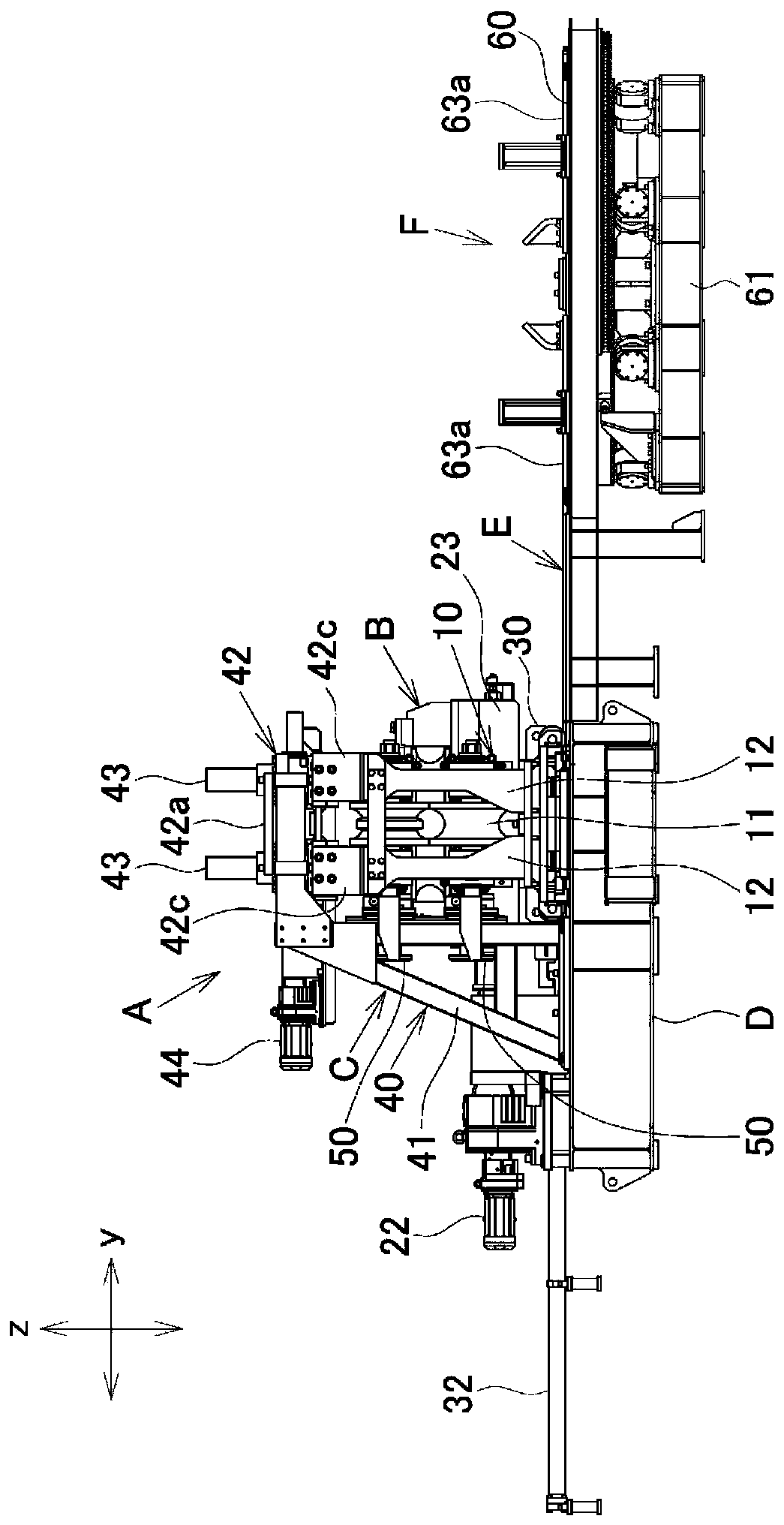

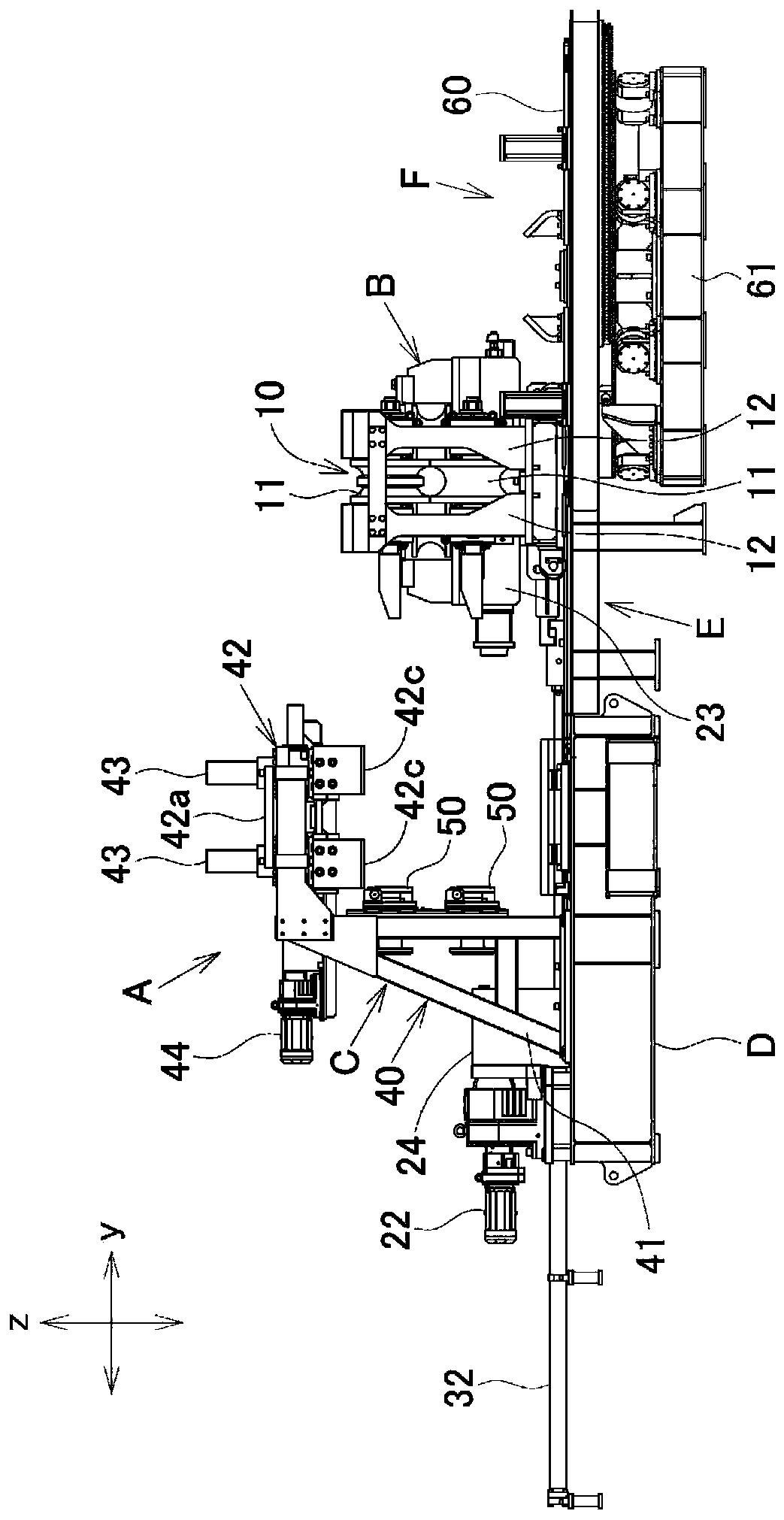

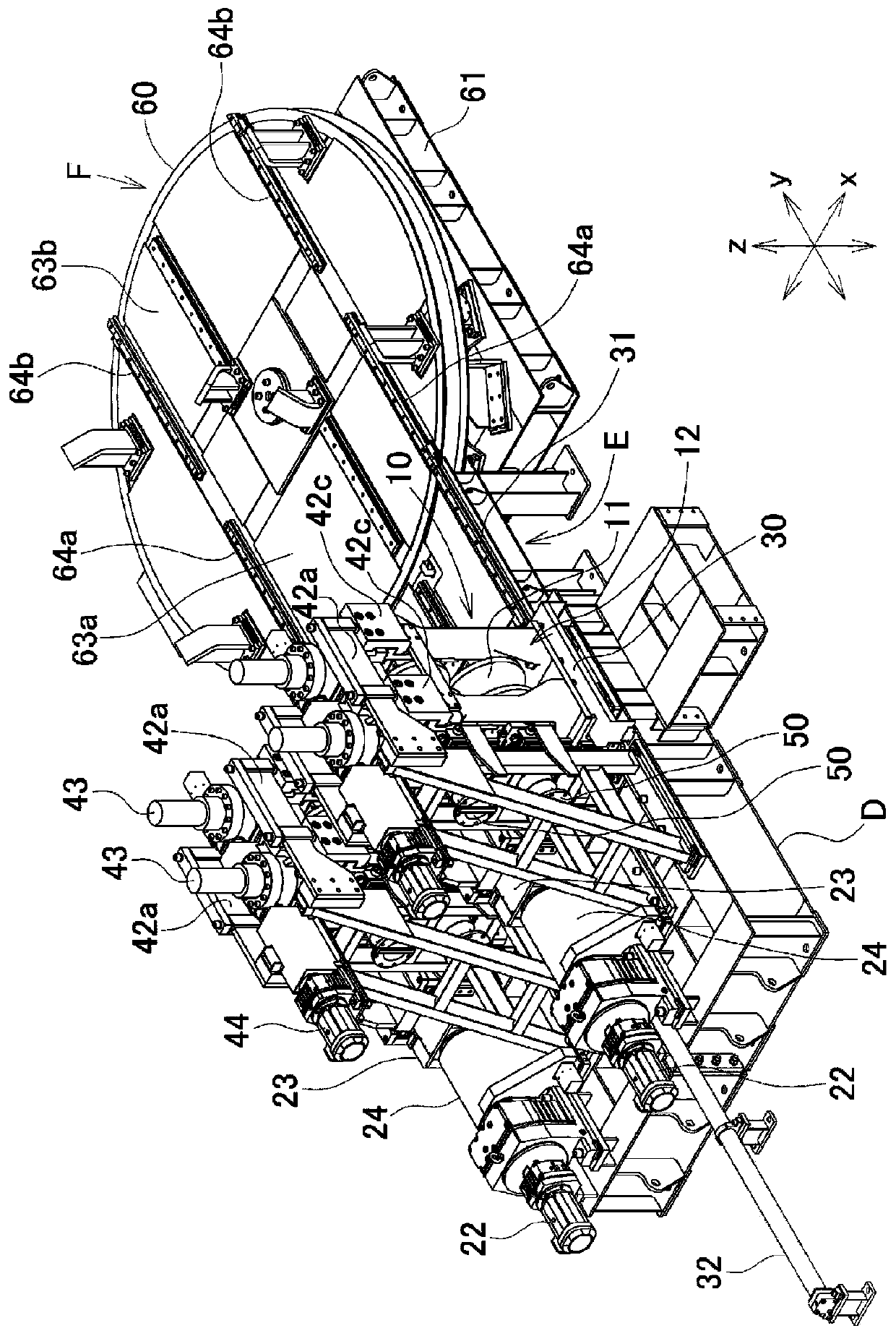

[0044] Next, an embodiment of the present invention will be described. The roll forming machine of this embodiment is a forming roll stand arranged on a production line of an electric welded steel pipe, and more specifically, the roll forming machine of this embodiment is an extrusion (hereinafter referred to as SQ) roll machine The row of fine forming (hereinafter referred to as FP) roll stands on the upstream side of the stand.

[0045] In addition, in the following description, the direction of the molding line is represented as the x direction, the horizontal direction at right angles to the x direction is represented as the y direction, the vertical direction at right angles to the x direction is represented as the z direction, and the direction of the molding line is The x direction is called the front-back direction, the y direction is called the left-right direction or the side, and the z direction is called the up-down direction. In addition, the horizontal roller in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap