roll forming machine

A forming machine and rolling technology, which is applied in the direction of forming tools, metal rolling stands, metal rolling mill stands, etc., can solve the problems of large-scale and high cost, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

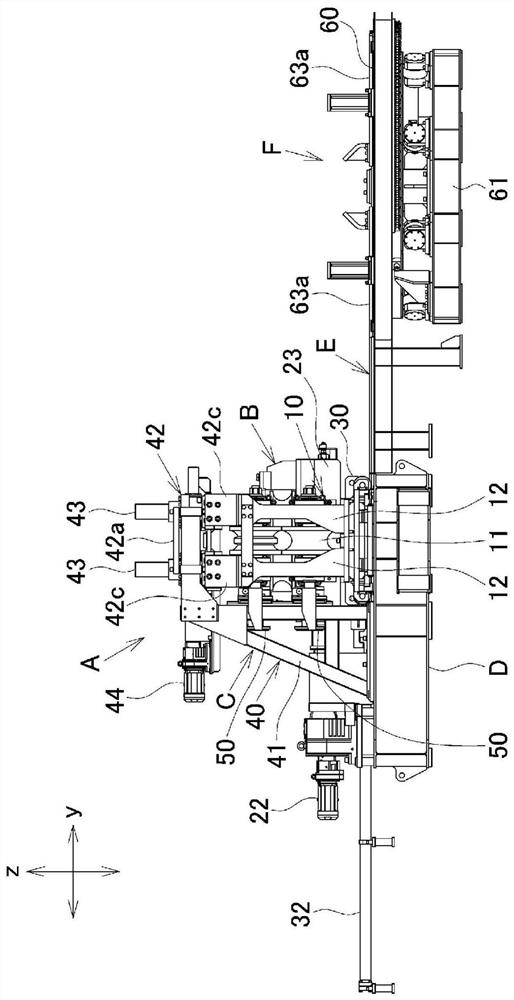

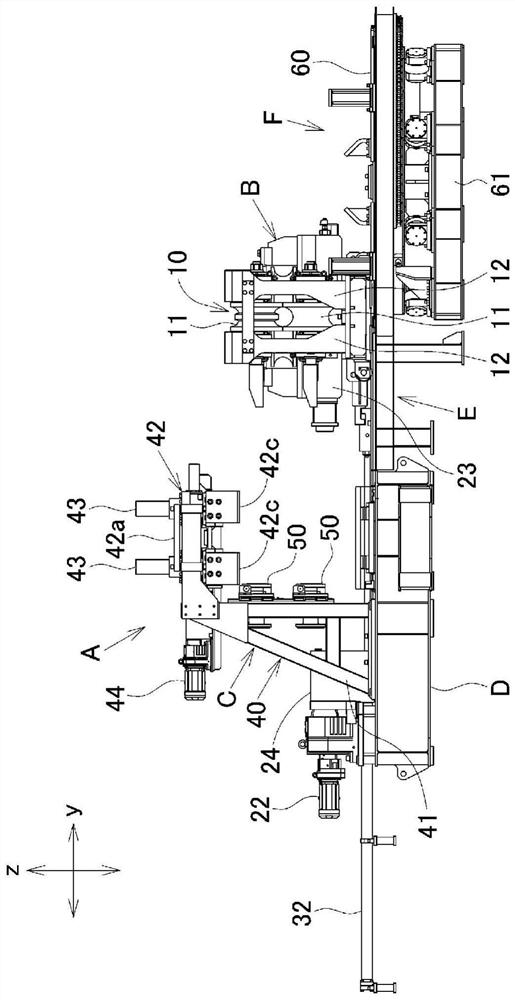

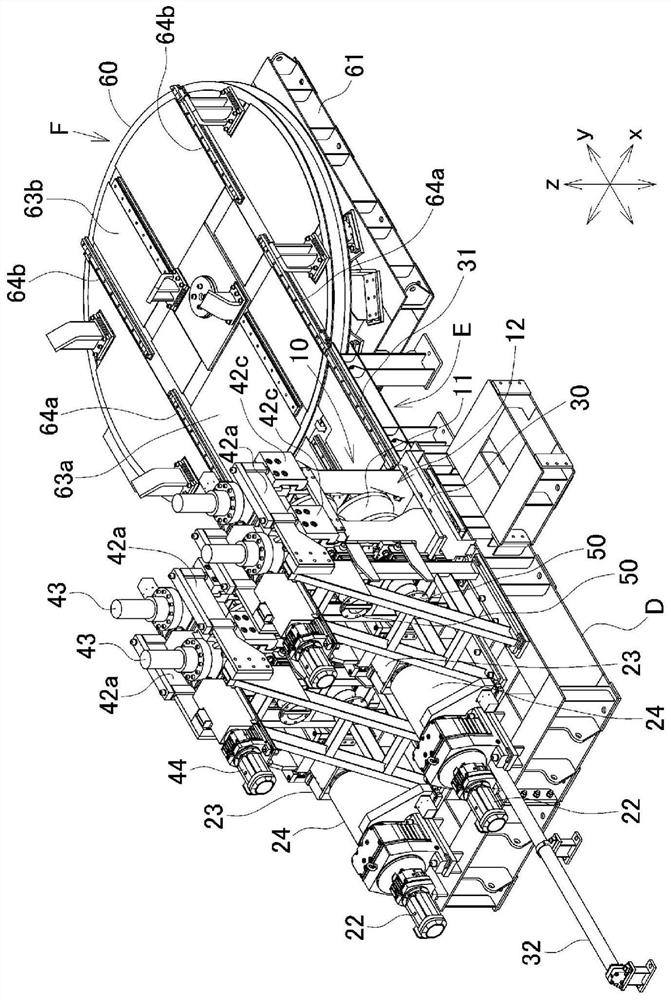

[0044] Next, an embodiment of the present invention will be described. The roll forming machine of the present embodiment is a forming roll stand arranged on a production line of electric resistance welded steel pipes, and more specifically, the roll forming machine of the present embodiment is a roll forming machine arranged on an extrusion (hereinafter referred to as SQ) A finish forming (hereinafter referred to as FP) roll stand row on the upstream side of the stand.

[0045] In addition, in the following description, the direction of the molding line is expressed as the x direction, the horizontal direction at right angles to the x direction is expressed as the y direction, the vertical direction at right angles to the x direction is expressed as the z direction, and the direction of the molding line is expressed as the z direction. The x direction is referred to as the front-rear direction, the y direction is referred to as the left-right direction or the lateral directio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap