Pressure startup device for air compressor

An air compressor and starting device technology, which is applied to machines/engines, mechanical equipment, liquid variable capacity machinery, etc. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

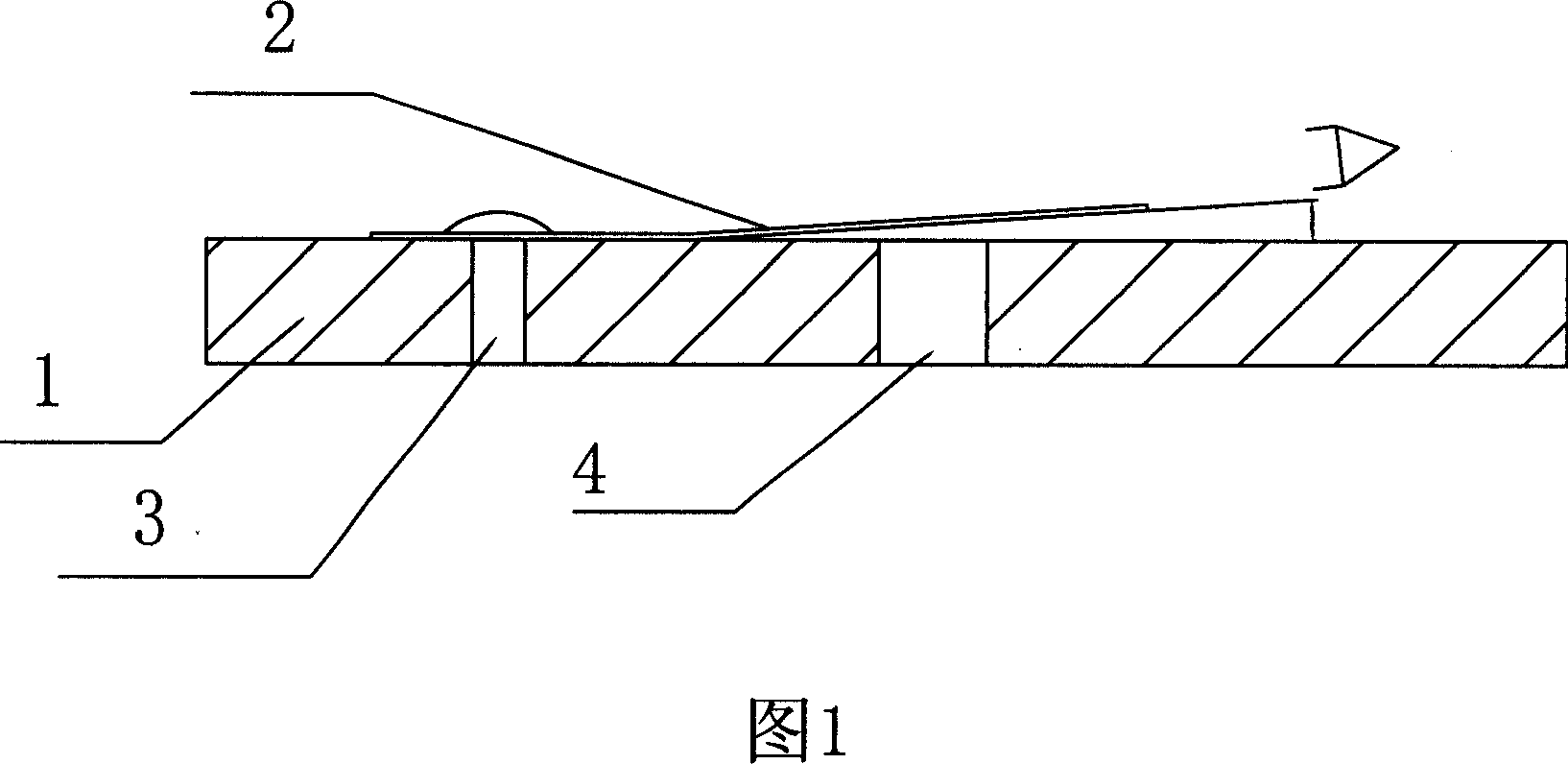

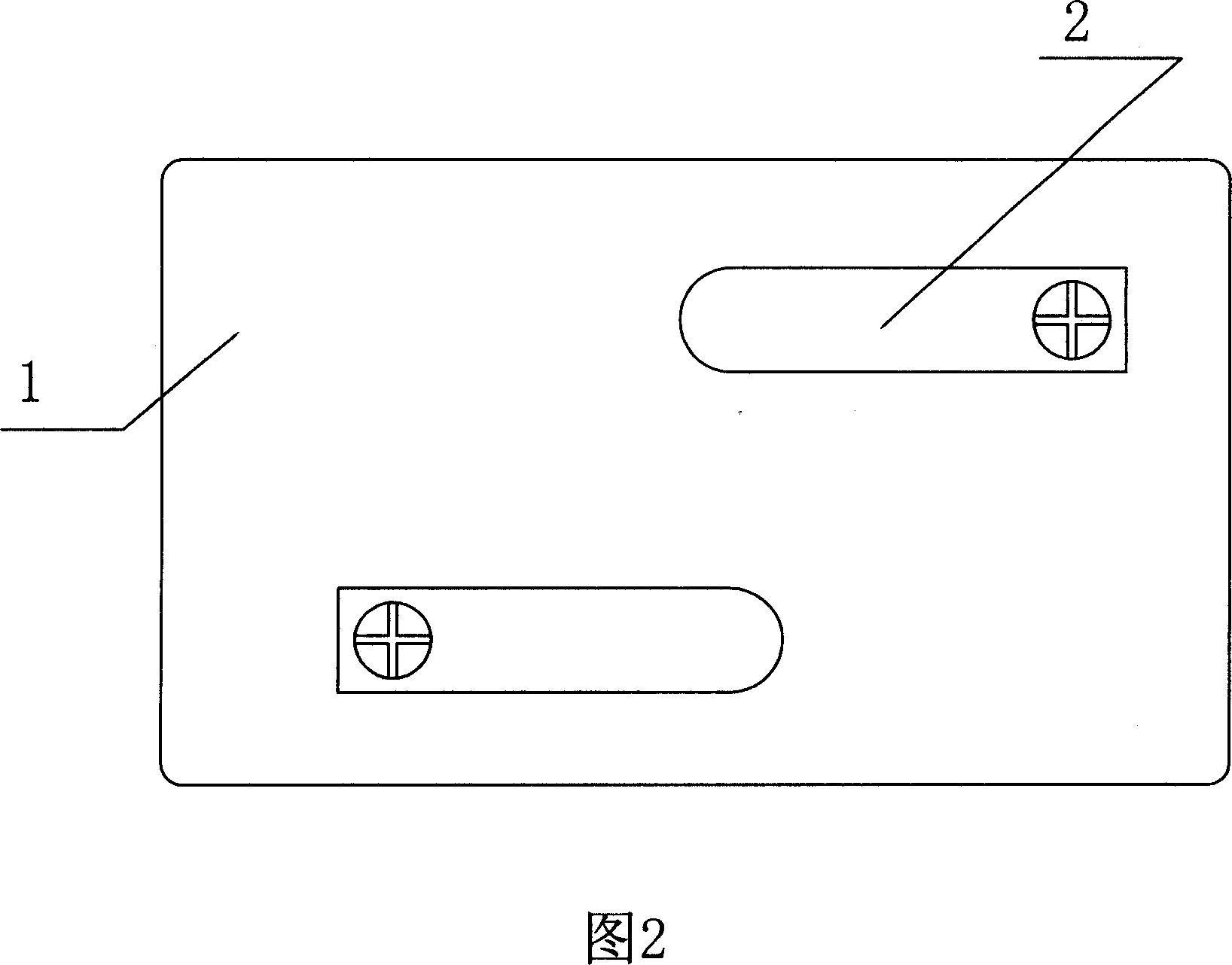

[0013] As shown in Figure 1 and Figure 2, the air compressor startup device under pressure of the present invention includes a valve plate 1 and a valve plate 2, the valve plate 1 is a metal plate, and there are inlet and outlet holes or grooves on the plate, and the valve plate 2 is formed Curved metal sheet, one end is bent up, and the other end is connected to the valve plate 1. The bending angle A is less than 25 degrees. The experiment proves that the best angle is when the angle A is 15 degrees; and it is fixed on the valve plate by screws 3 1, the valve plate 1 at the lower part of the curved part of the valve plate 2 is provided with intake and exhaust holes 4. In this embodiment, there are two valve plates fixed on the valve plate, and the directions of the fixed ends are opposite to each other, that is, when one left end When one side is fixed and the right end is bent upward, the other is fixed with the right end and the left end is bent upward. This is more conduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com