Motor speed control system and load inertia estimating method using inverse operating model

A load inertia and motor technology, applied in the control system, motor parameter estimation/correction, AC motor control, etc., can solve the problems that the estimated value has a great influence and the estimated value of the load inertia Jl changes greatly, and achieves fast convergence Steady-state error easing, the effect of fast convergence load inertia estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Specific embodiments are given below to describe the content of the present invention in detail, and the accompanying drawings are used as auxiliary descriptions. The symbols mentioned in the description refer to the reference symbols.

[0046] The present invention mainly utilizes an inversion system to inversely deduce the actual torque output, and then uses an adaptive algorithm to estimate the actual load inertia, so as to achieve the purpose of real-time estimation and precise control.

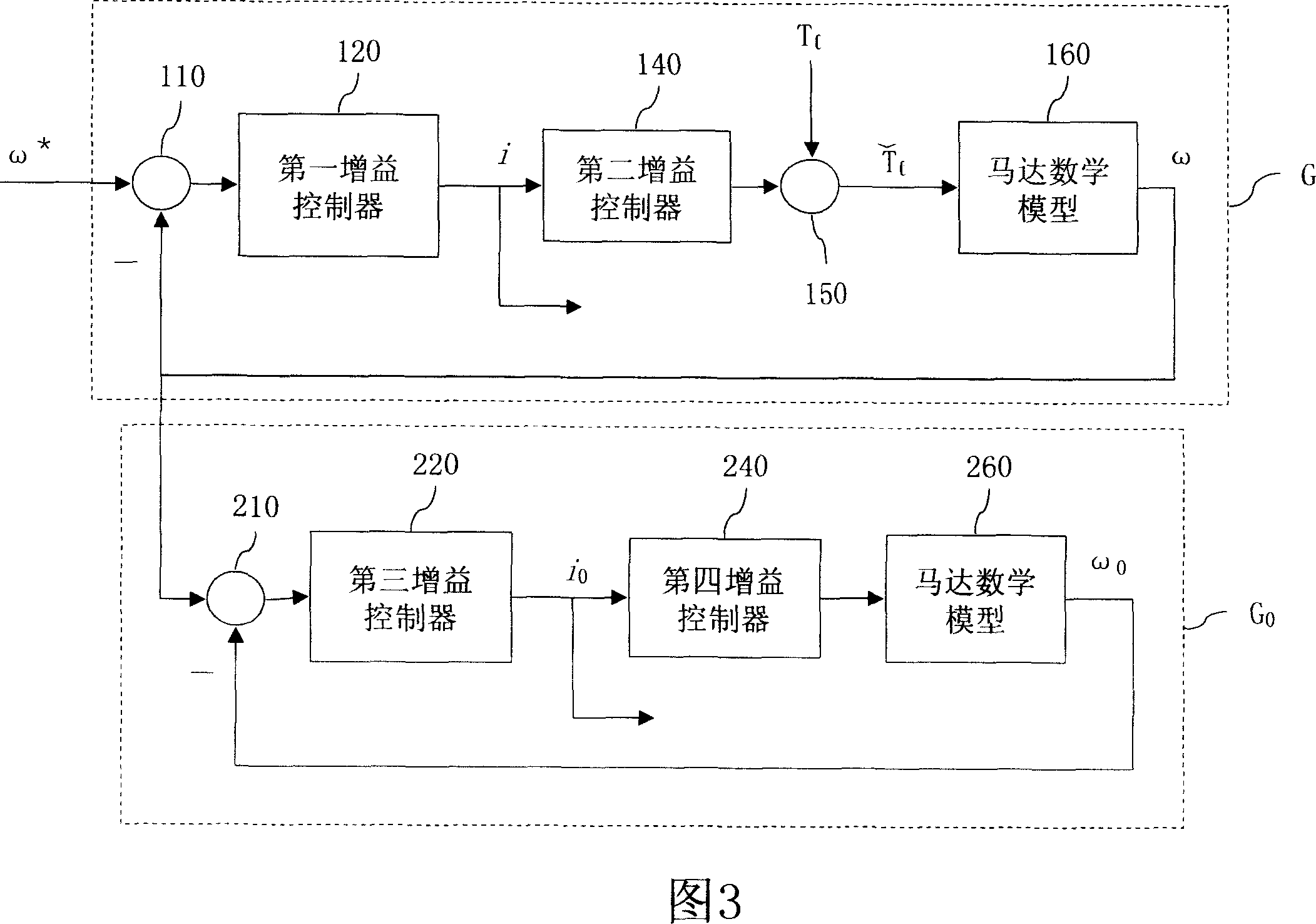

[0047] Referring to FIG. 3 , it is a motor speed control system using an inverse calculation mode according to an embodiment of the present invention, which is applied to an AC servo module, and mainly consists of an actual system G and an inverse calculation system G 0 composed of.

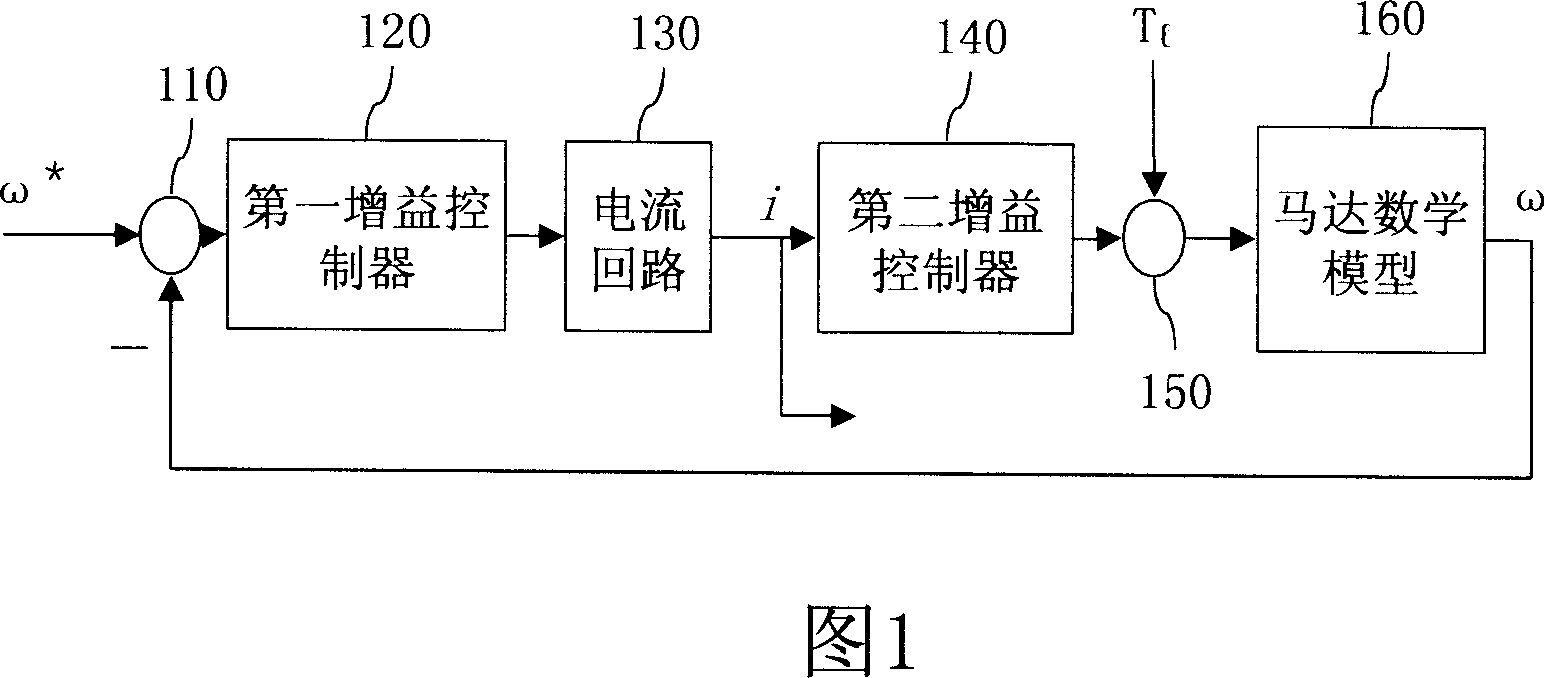

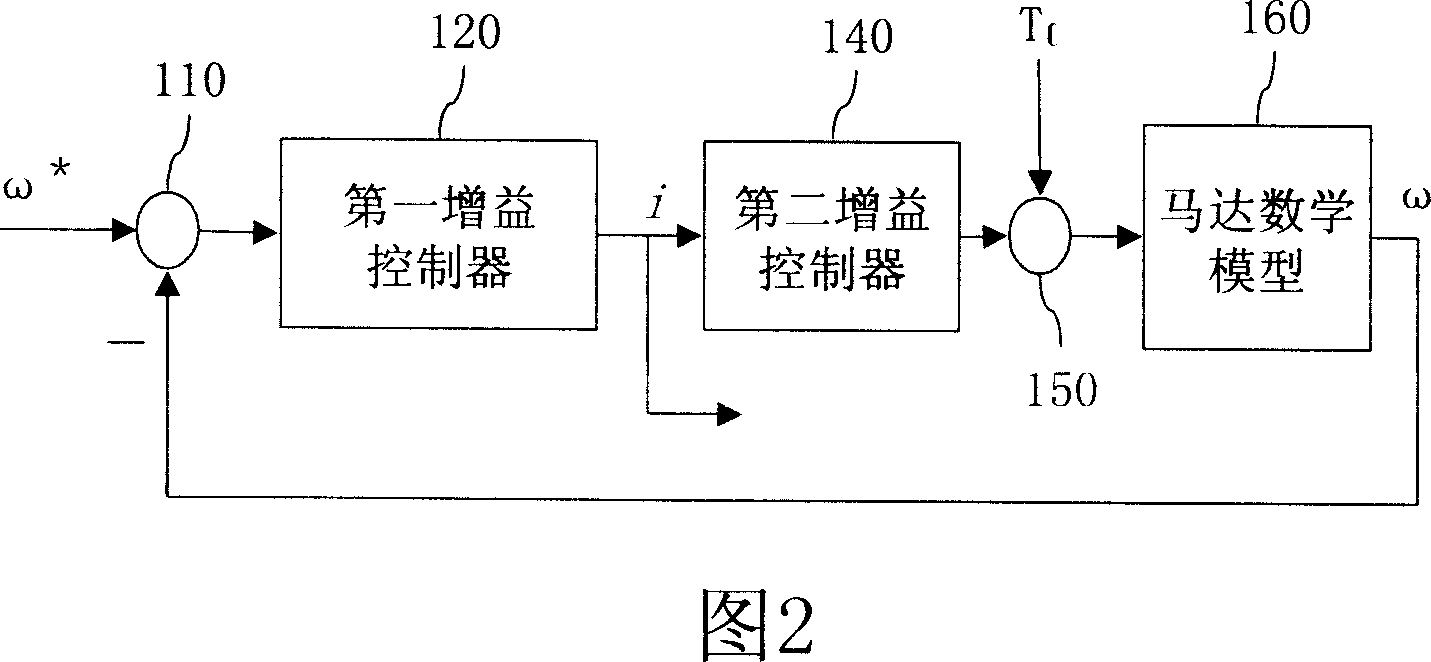

[0048] The component composition and operation of the actual system G are substantially the same as those of the conventional motor speed control system described above, so the description will not b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com