Chucking device

A technology of clamping device and main body, which is applied in the field of disk devices, and can solve problems such as large loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] Next, a clamping device according to an embodiment of the present invention will be described.

[0088] First, the hub main body constituting the clamp device according to the present embodiment will be described.

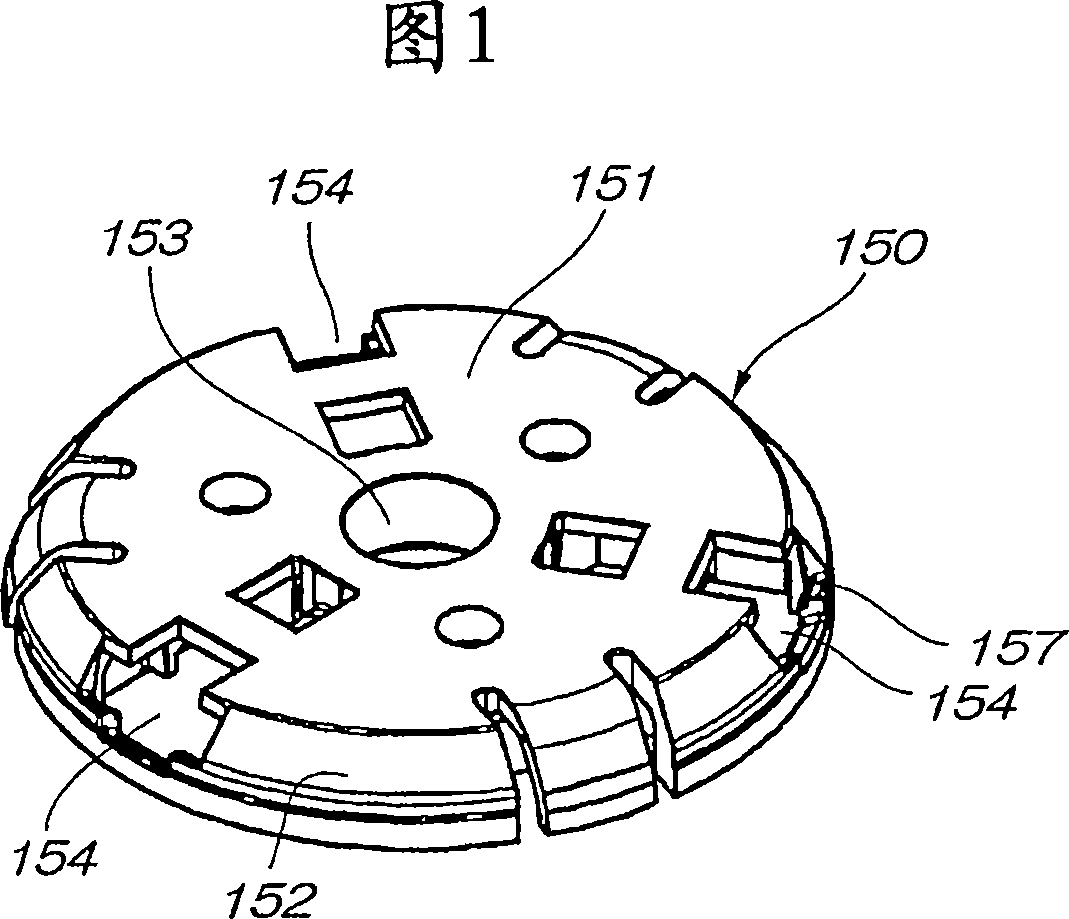

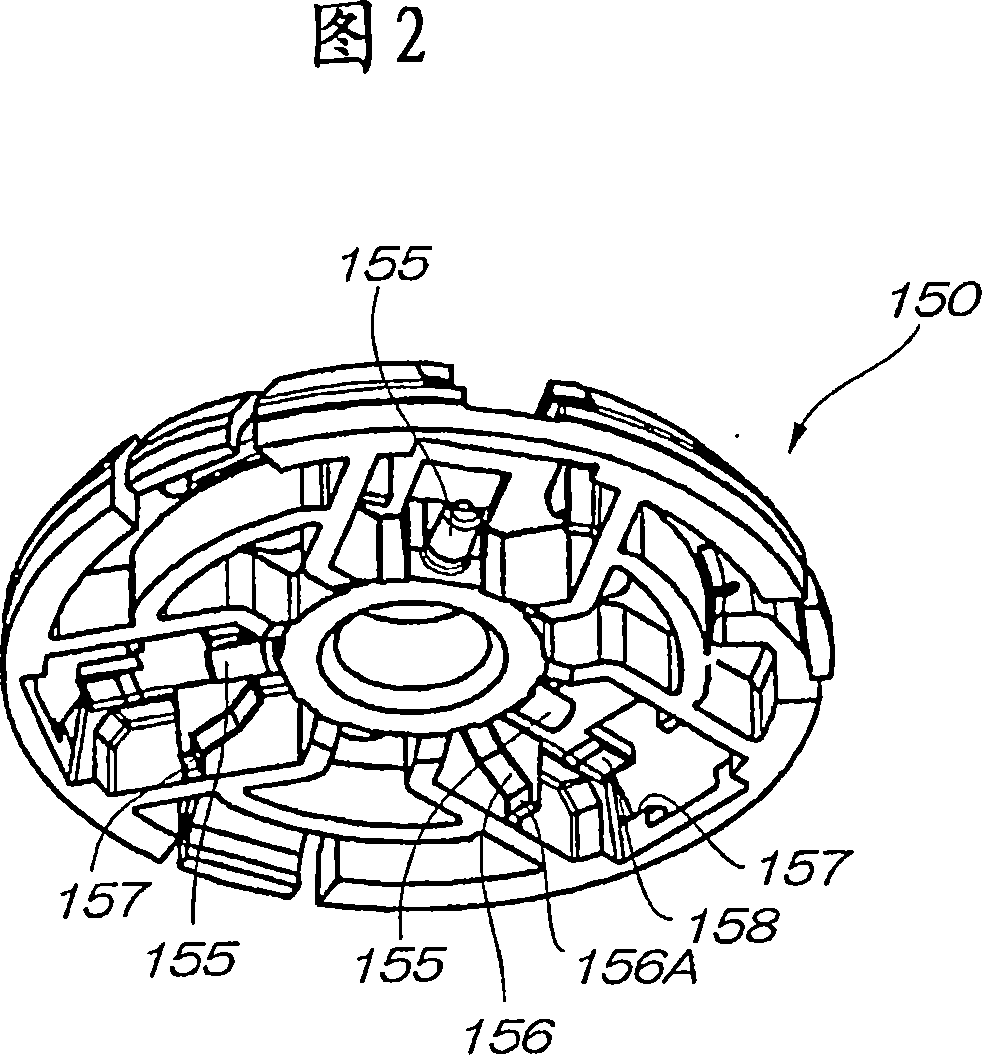

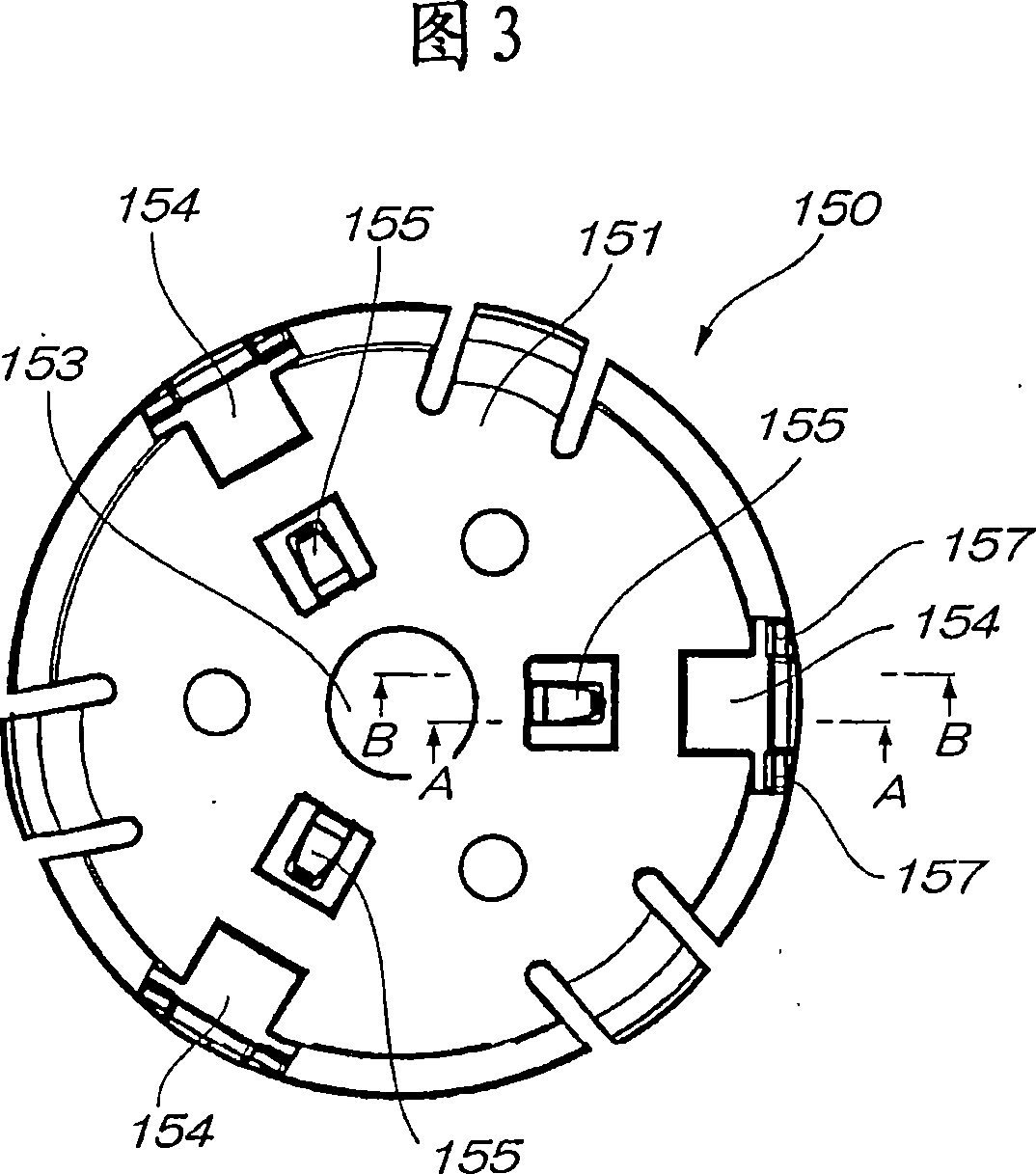

[0089] 1 is an upper side perspective view of a hub body of a clamping device according to the present embodiment, FIG. 2 is a lower side perspective view of the hub body, FIG. 3 is a front view of the hub body, and FIG. 4 is a rear view of the hub body. 5 is a side view of the hub main body, FIG. 6 is a sectional view of A-A in FIG. 3 , and FIG. 7 is a sectional view of B-B in FIG. 3 .

[0090] The hub body 150 of the turntable is formed into a dish shape by a disc-shaped upper surface 151 and side surfaces 152 erected on the outer periphery of the upper surface 151 . In the center portion of the upper surface 151, a motor shaft hole 153 is formed to engage with the rotation shaft of the spindle motor.

[0091] Three pawl openings 154 are radially provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com