Control method for a continuously variable transmission

A technology of continuously variable transmission and control method, applied in the direction of transmission control, elements with teeth, belt/chain/gear, etc., can solve the problems of increasing high level, instability, transmission damage, etc., and achieve cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

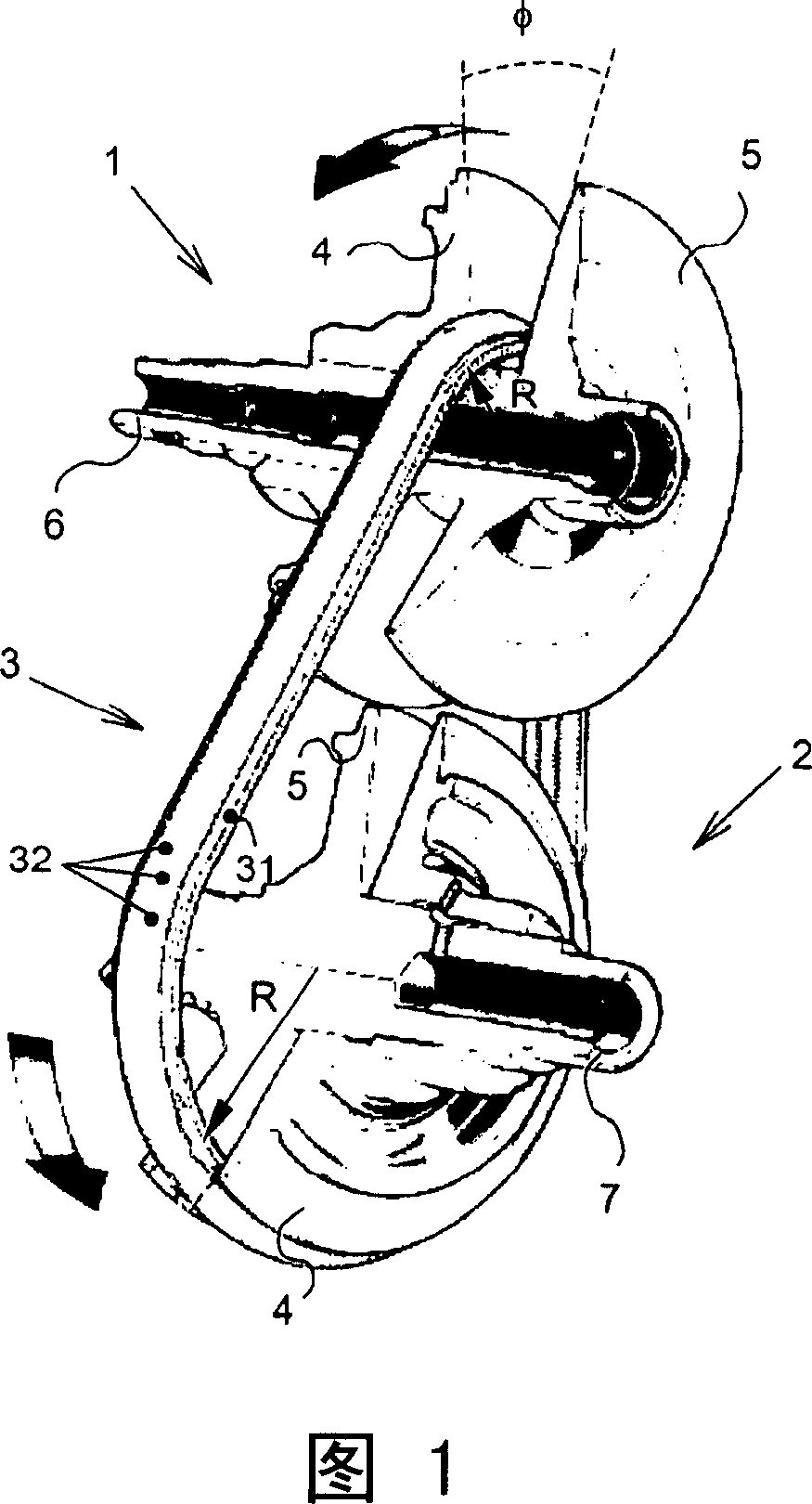

[0026]FIG. 1 shows a main part showing a continuously variable transmission used in a vehicle such as a passenger car. The variator is known per se and comprises a primary pulley 1 and a secondary pulley 2 with a drive belt 3 arranged between them, each pulley comprising two pulley pulleys 4 , 5 respectively. The pulley sheaves 4, 5 are of conical form to define wedge-shaped grooves, and at least one sheave 4 of each pulley 1, 2 is axially movable along a respective shaft 6, 7, the sheaves 4, 5 placed on the axis. In addition, the transmission comprises actuating means (not shown in the figures), usually electrically controllable and hydraulically actuated, capable of applying an axial force Fax to said one disc 4 in such a way that The drive belt 3 can be clamped between the respective pulleys 4, 5 and can move between the pulleys 1, 2 by means of friction in the conical (wedge-shaped) contact surface between the pulleys 4, 5 and the drive belt 3 transmission of mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com