Traction device

A pulling device and flat winding technology, applied in transportation and packaging, winding strips, thin material processing, etc., can solve the problems of increased workload, high operating costs, slowing down the progress of coiling processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Reference will now be made to various embodiments according to the invention, examples of which are illustrated in the accompanying drawings and will become apparent to those skilled in the art from the description of the invention. In the different drawings, the same reference numerals designate the same or similar parts.

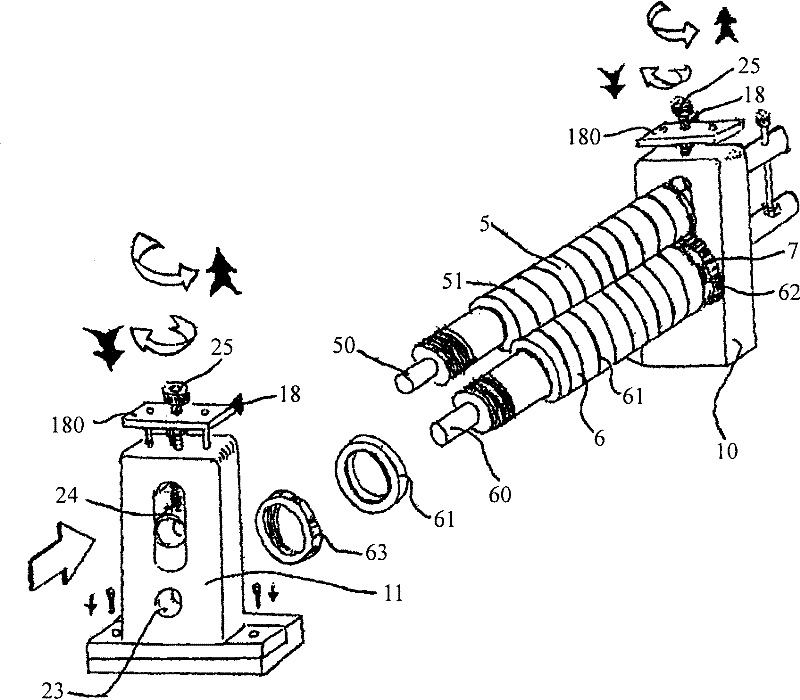

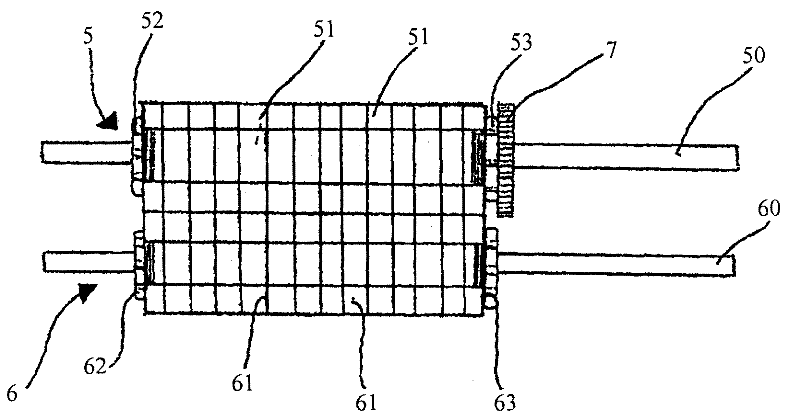

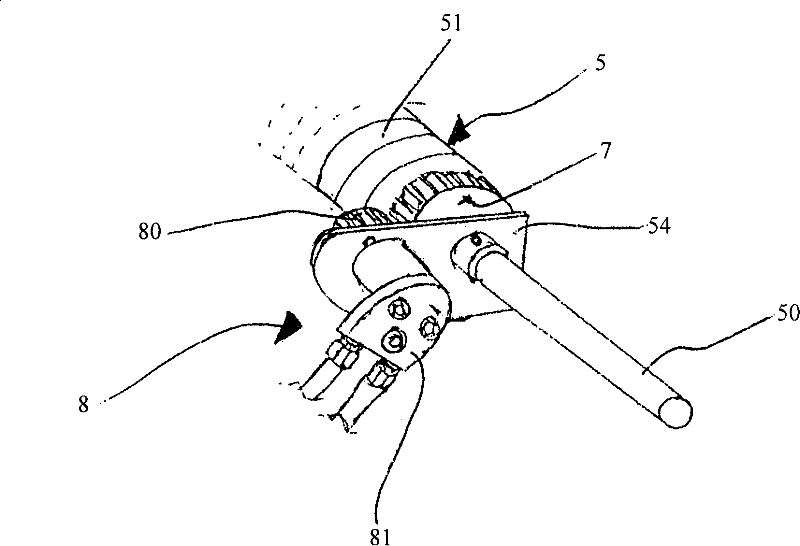

[0031] figure 1 Shown is a front view of a pair of rollers according to a preferred embodiment of the present invention. The pair of rolls consists of an upper roll 5 and a lower roll 6 . Both roll 5 and roll 6 are cylindrical rolls and are parallel to each other along the respective axis directions during the coiling process. Each roller 5 and 6 comprises a shaft 50 and 60 respectively; at least one protective ring 51 and 61, in particular made of rubber or polyurethane, is used to protect the coiled strip while guiding it through the two rollers 5 and 6 The surface of the winding strip is protected from damage; spacer rings and contact elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com