Differential pressure type liquid level detector

A technology of liquid level detection and pressure difference, which is applied in the direction of displaying liquid level indicators through pressure measurement, which can solve the problems of difficult liquid level detection, slow detection speed, and high failure rate, so as to avoid misoperation, uniform lift, and failure low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

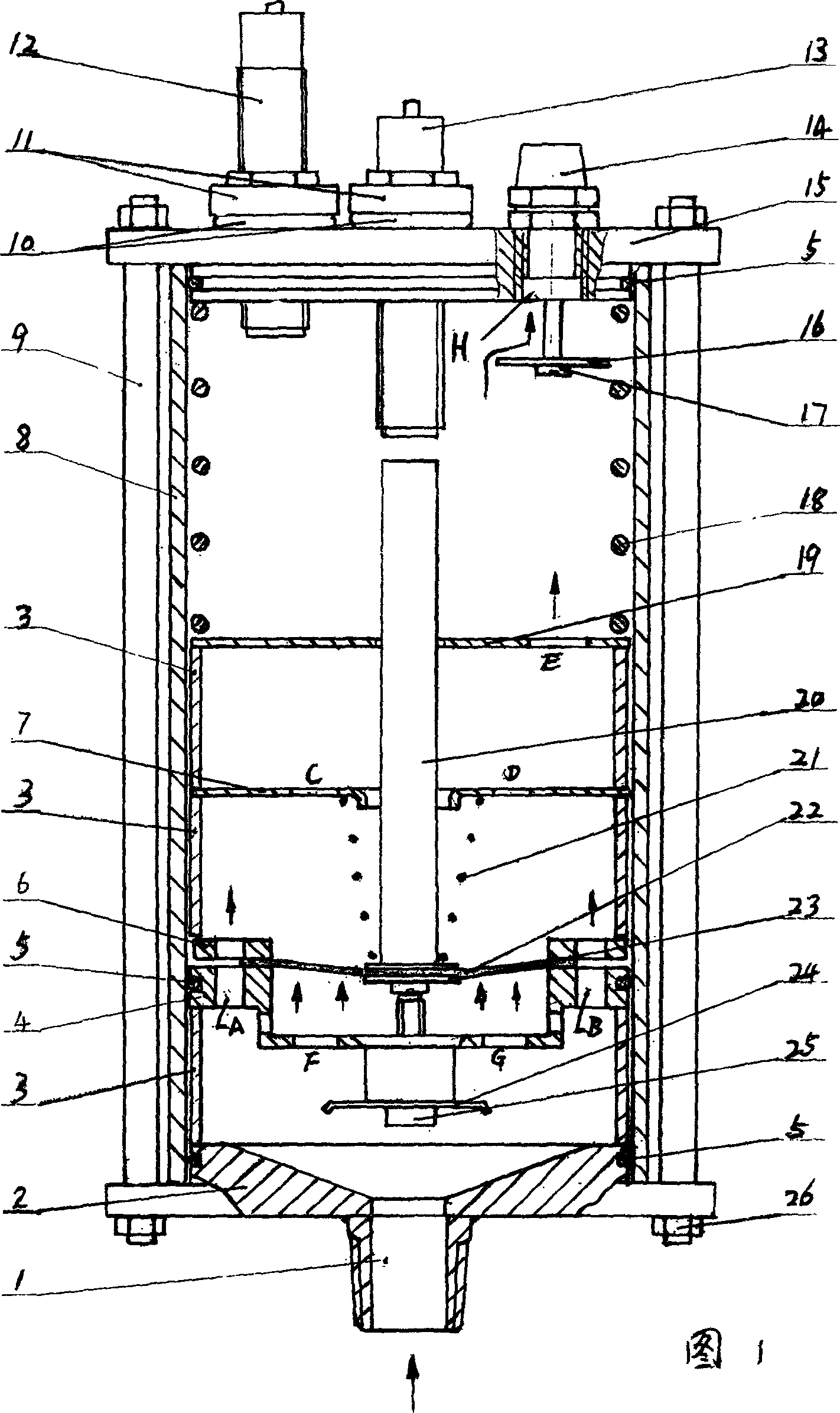

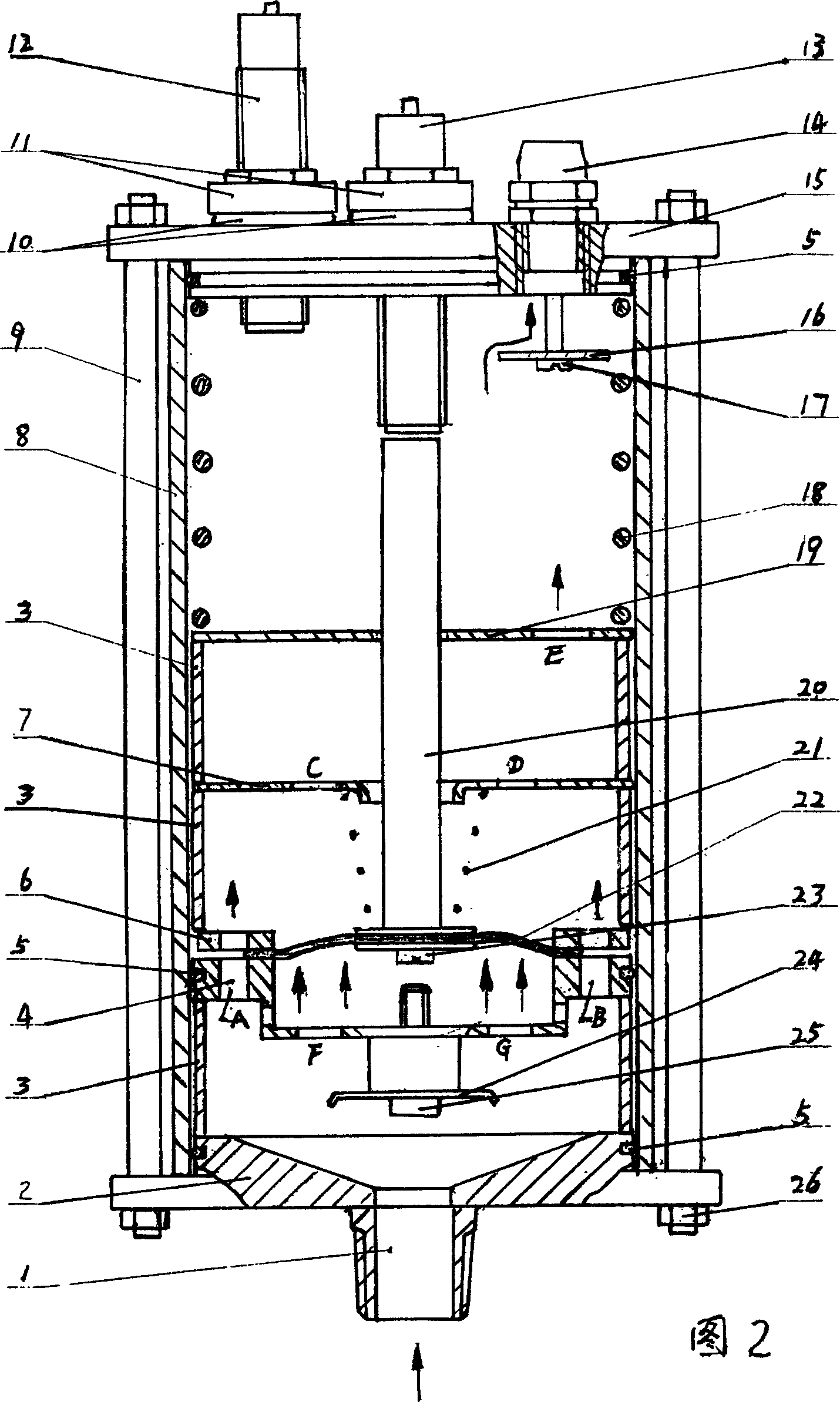

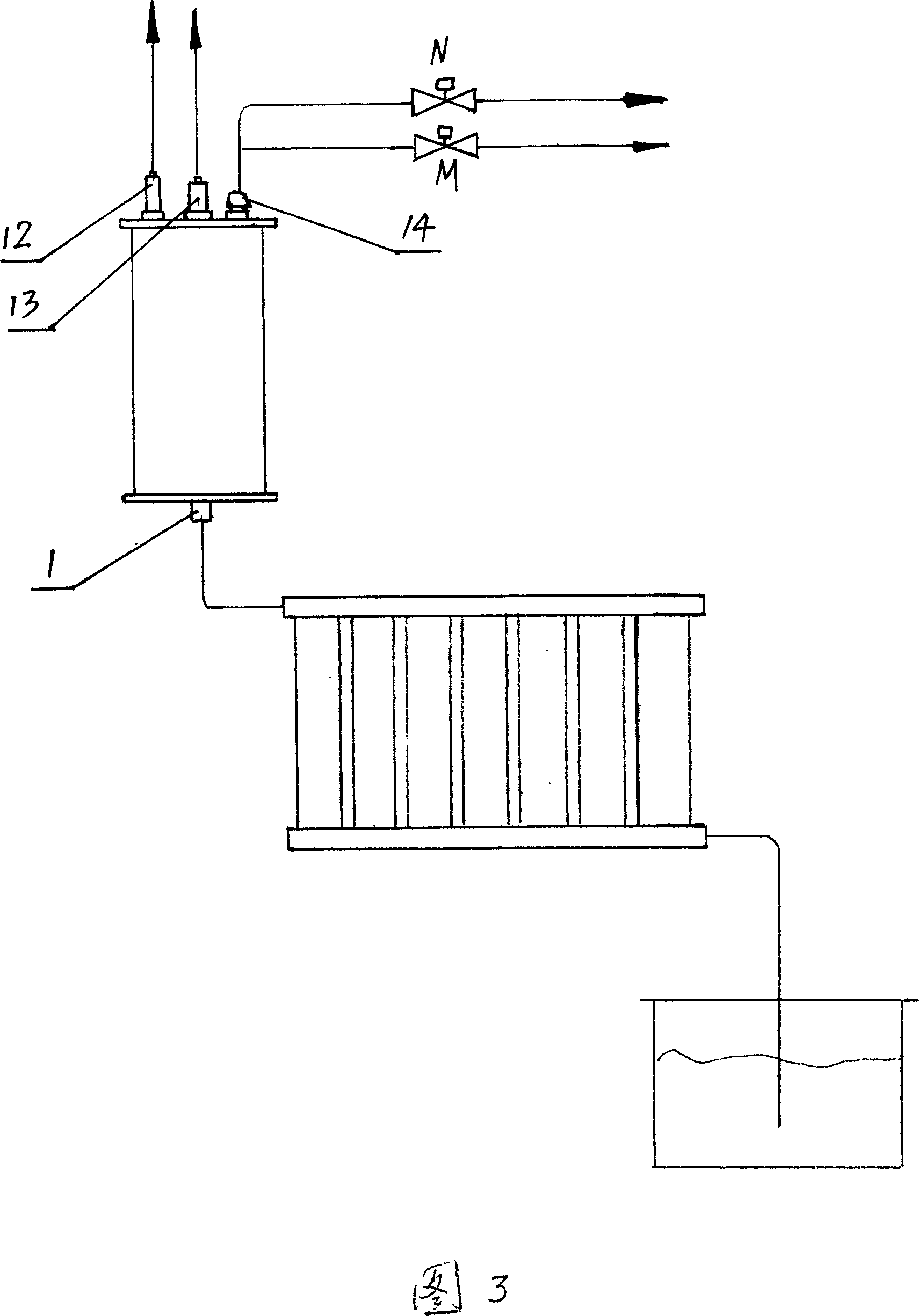

[0019] Referring to the accompanying drawings, the differential pressure type liquid level detection device includes a cylinder body 8 with upper and lower closure covers, a liquid inlet is provided on the lower closure cover 2, and a liquid inlet wire head 1 is installed on the liquid inlet. The upper sealing cover 15 is provided with a suction port H, on which a locking joint 14 is installed, and below the suction port H is provided with a splash-proof partition 16 for the suction port, and the splash-proof partition 16 is supported by bolts 17 and closed on the top. Cover 15. Diaphragm seat 4, liquid baffle plate 7 and splash baffle plate 19 are arranged alternately from bottom to top in the inner cavity of cylinder body 8, between lower closure cover 2 and diaphragm seat 4, diaphragm pressure plate 6 and liquid baffle plate Positioning spacers 3 are respectively provided between the partitions 7 and between the liquid-blocking partitions 7 and the splash-proof partitions 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com