Locomotive top cap sealing method and device

A top cover sealing and sealing device technology, which is applied in the direction of locomotive propulsion, locomotives, motor vehicles, etc., can solve the problems of permanent deformation and resilience of sealing strips, complex process, shrinkage, etc., to improve the stress situation and simplify the production process , The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

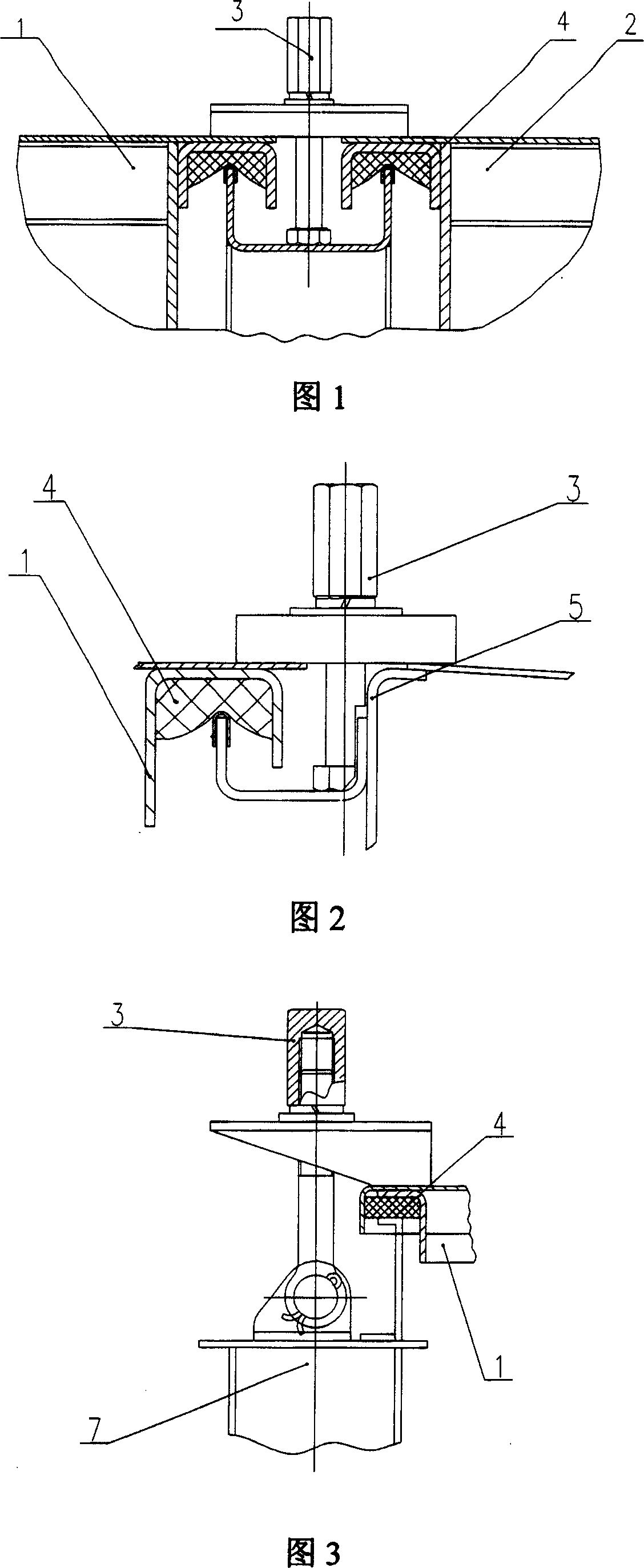

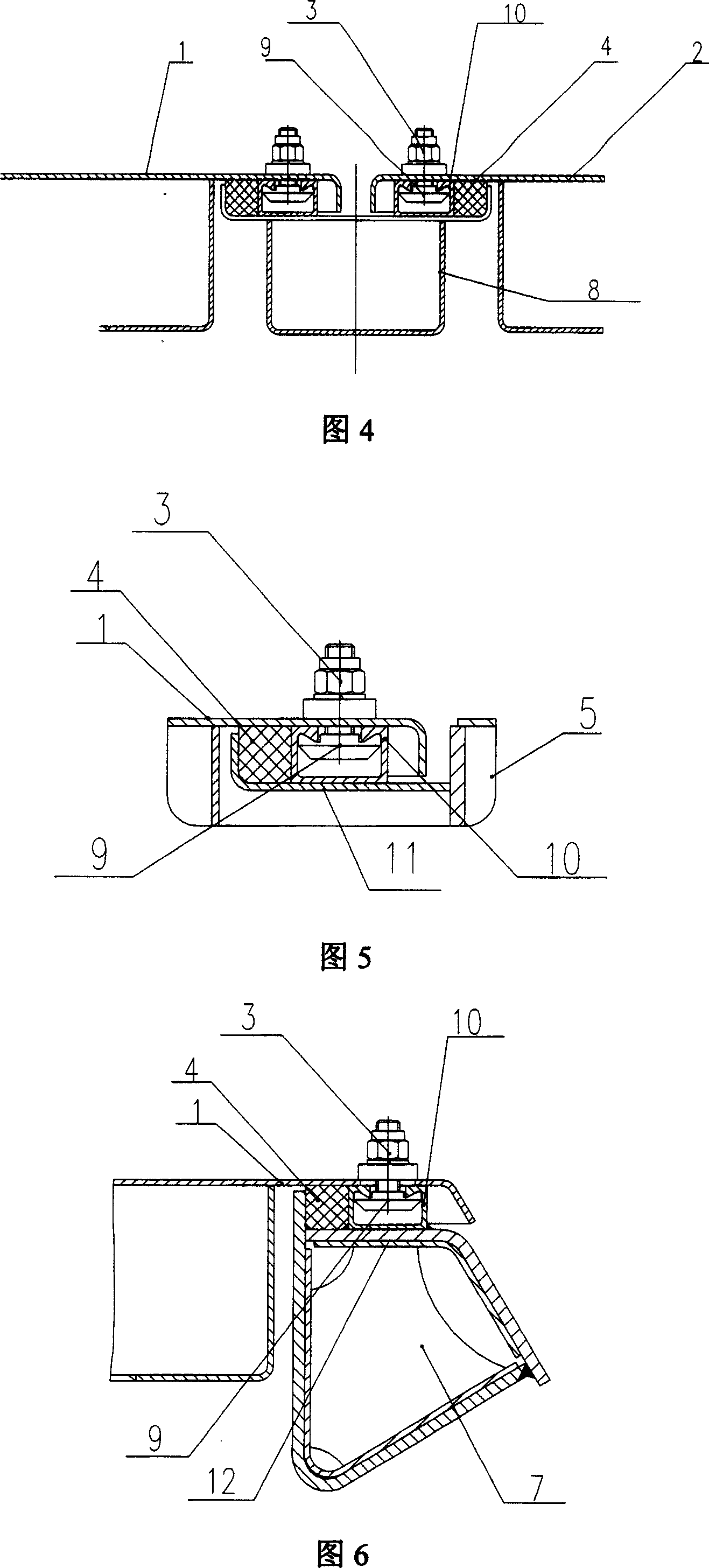

[0019] The accompanying drawings show an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

[0020] It can be seen from the accompanying drawings that the present invention is a method and device for sealing a roof cover of a locomotive. The present invention adopts a wide-side sealed locomotive roof sealing method, allowing the entire sealing strip to be compressed and sealed as a whole, and the locomotive roof and the locomotive roof, and the locomotive roof and the locomotive end wall are realized through a wider sealing strip. And the seal between the locomotive end wall and the locomotive roof.

[0021] The device provided according to the method of the present invention is a wide-side locomotive roof sealing structure. 4 Combination structure, wherein, the auxiliary sealing strip 3 is provided between the locomotive roof 1 and the locomotive roof 2, the locomotive roof 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com