Microleak automatic protection apparatus based on microflow detection

An automatic protection, micro-flow technology, used in measuring devices, fluid velocity measurement, fluid tightness testing, etc., can solve the problems of low safety, short effective service life, pipeline influence, etc. High detection accuracy and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

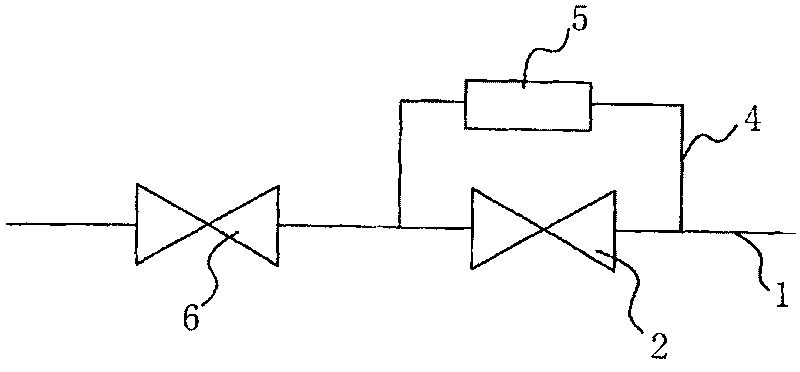

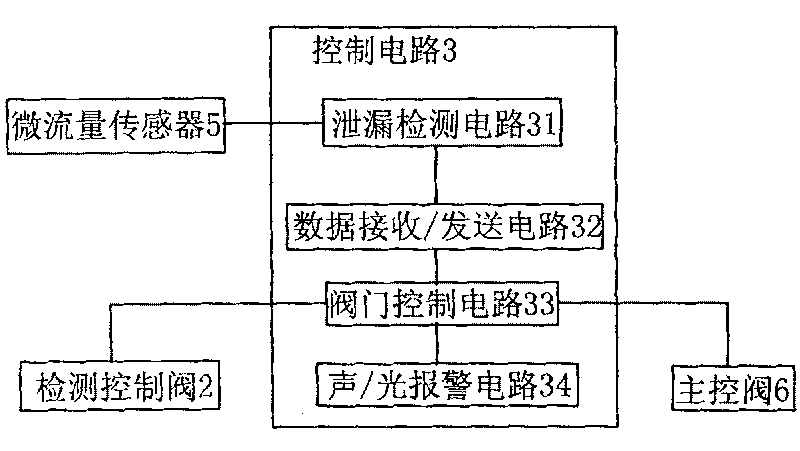

[0029]Such as figure 1 and figure 2 As shown, the automatic protection device for micro-leakage based on micro-flow detection is set on the delivery pipeline. It consists of a micro flow sensor 5, a control circuit 3, a detection channel 4, a detection control valve 2, a main control valve 6 and other components.

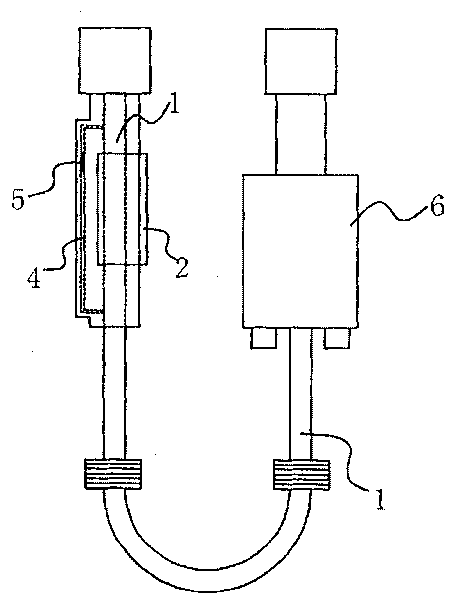

[0030] Such as image 3 As shown, the detection control valve 2 is installed on the main pipeline 1, and the control circuit 3 is connected with the detection control valve 2. The main pipeline 1 is connected with a detection channel 4 whose diameter is much smaller than that of the main pipeline 1 . The two ends of the detection channel 4 are respectively located at the two ends of the detection control valve 2 . A micro-flow sensor 5 is arranged in the detection channel 4 , and the micro-flow sensor 5 is connected with the control circuit 3 . The detection channel 4 and the main pipeline 1 are arranged on the same pipe, the detection channel 4 is located on t...

Embodiment 2

[0037] Such as Figure 5 As shown, in this embodiment, the detection channel 4 is located on the outer wall of the main pipeline 1, that is, a channel is opened outside the pipeline, and the rest are the same as in the embodiment 1, which will not be repeated here.

Embodiment 3

[0039] In this embodiment, the detection channel 4 is in the shape of a circular tube, and a flat channel 41 is arranged in the middle thereof, and the micro flow sensor 5 is arranged on the inner wall of the flat channel 41 . That is, a passage is opened in the pipeline, and the rest are the same as those in Embodiment 1 or 2, and will not be described in detail herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com