Flat board display of fold-line type grid controlled structure and manufacture process

A technology of flat panel display and manufacturing process, which is applied in the direction of control electrode, discharge tube/lamp manufacturing, image/graphic display tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

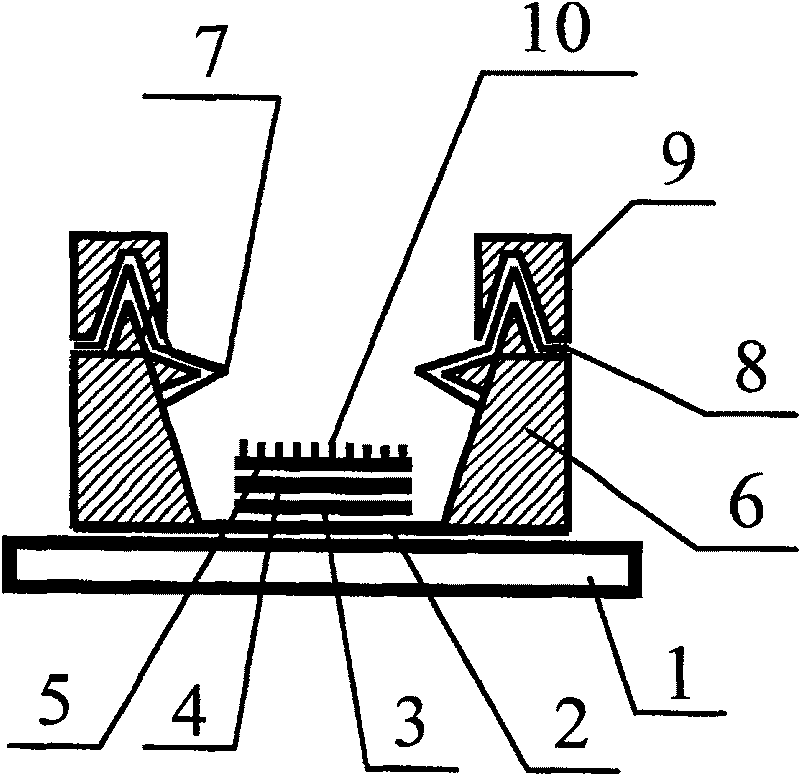

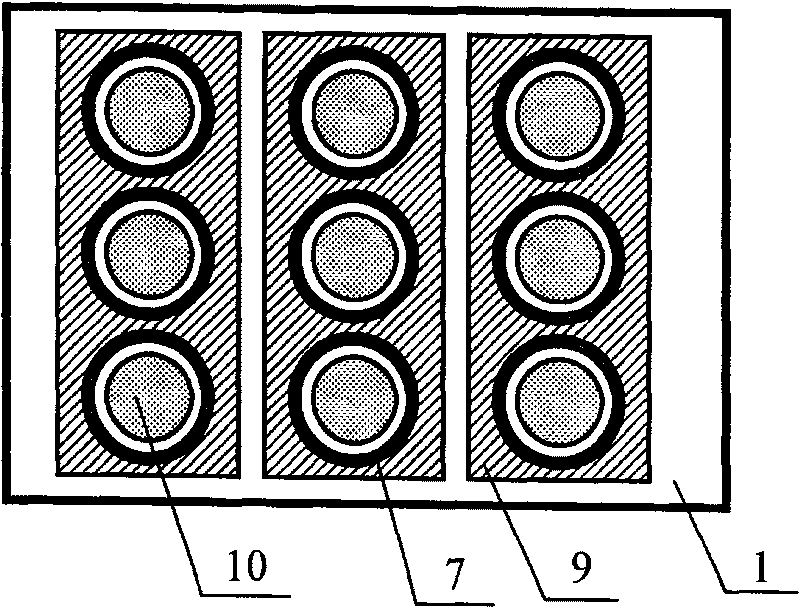

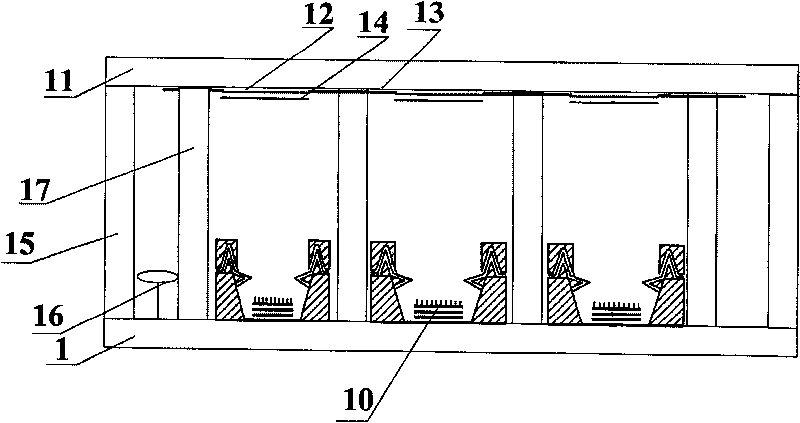

[0038]The flat panel display with a zigzag grid control structure includes a sealed vacuum cavity formed by a cathode glass panel [1], an anode glass panel [11] and surrounding glass frames [15]; There is an anode conductive layer [12], a phosphor layer [14] prepared on the anode conductive layer, and an insulating paste layer [13] printed on the non-display area of the anode conductive layer; located between the anode glass panel and the cathode glass panel The supporting wall structure [17] and the accessory component of the getter [16] are characterized in that: there are a cathode conductive layer [5], a carbon nanotube [10] and a zigzagging grid control structure on the cathode glass panel.

[0039] The zigzag gate control structure includes a cathode glass panel [1], a retardation la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com