Axial-displacement cutter carriage structure of miller

A milling device and axial displacement technology, applied in positioning devices, milling machine equipment, details of milling machine equipment, etc., can solve the problem of not being able to simultaneously mill holes, hole holes or drilling, waste of energy resources, and load on the spindle and its helical gears. Heavy and other problems to achieve the effect of improving operation convenience and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

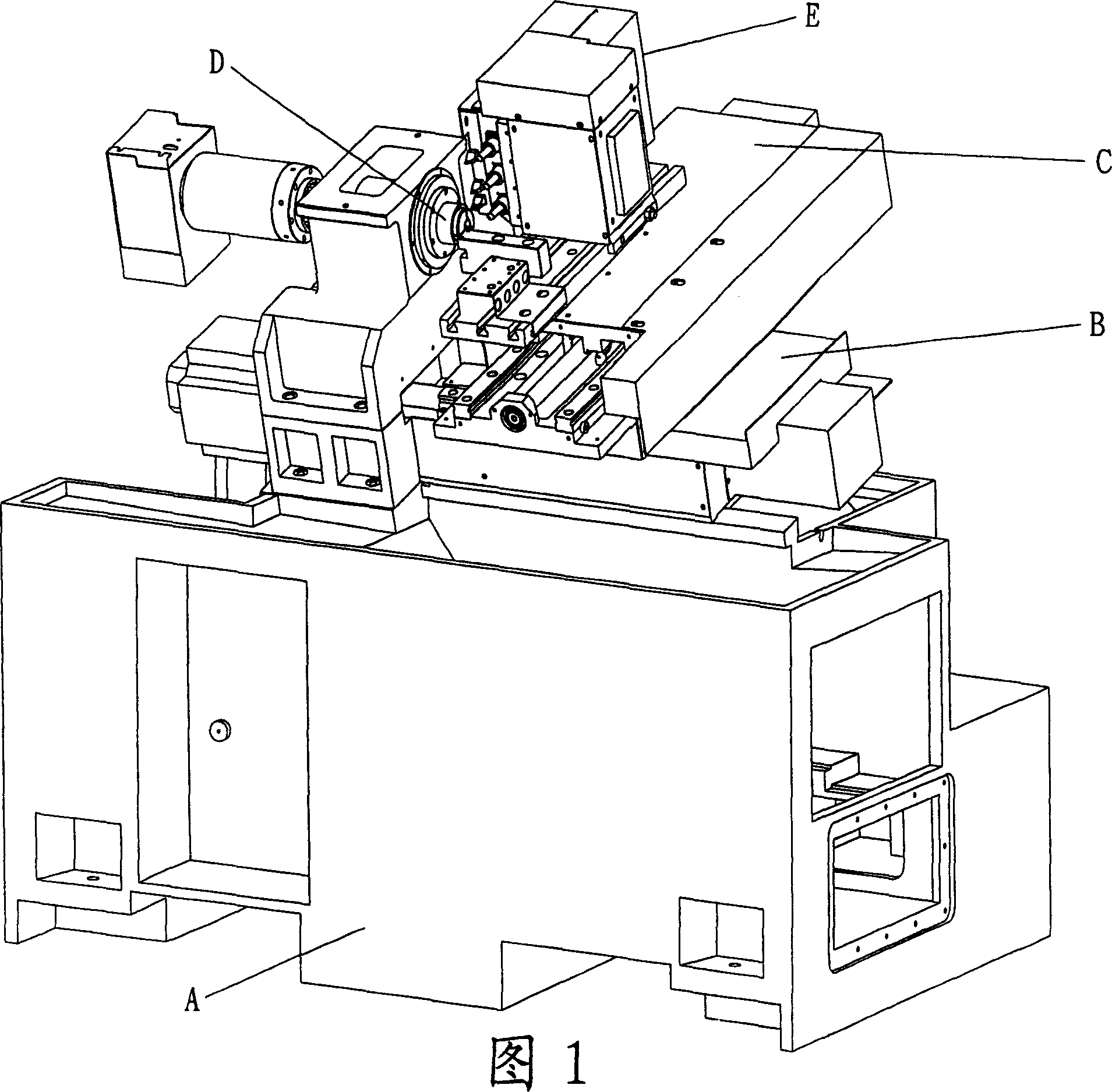

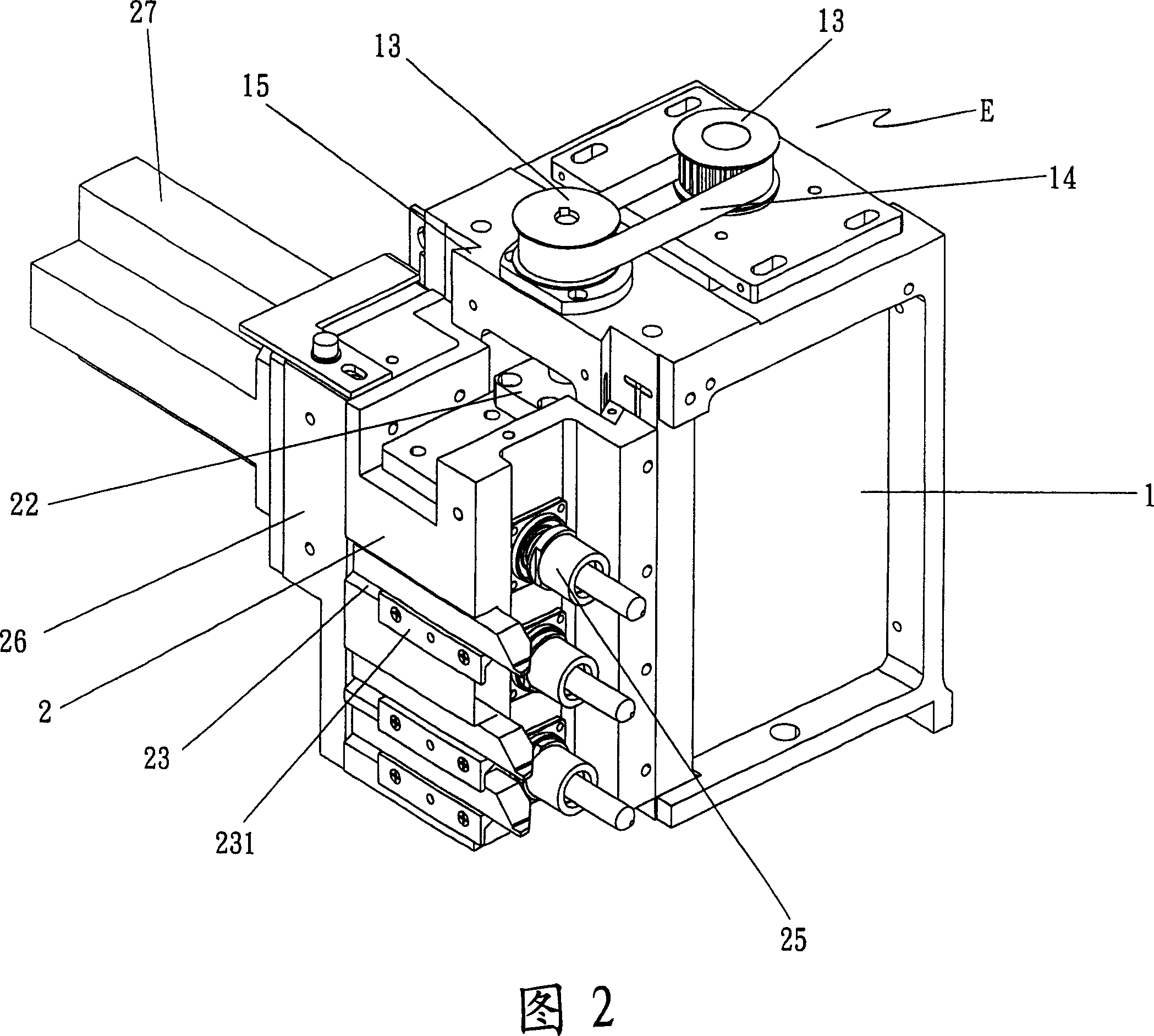

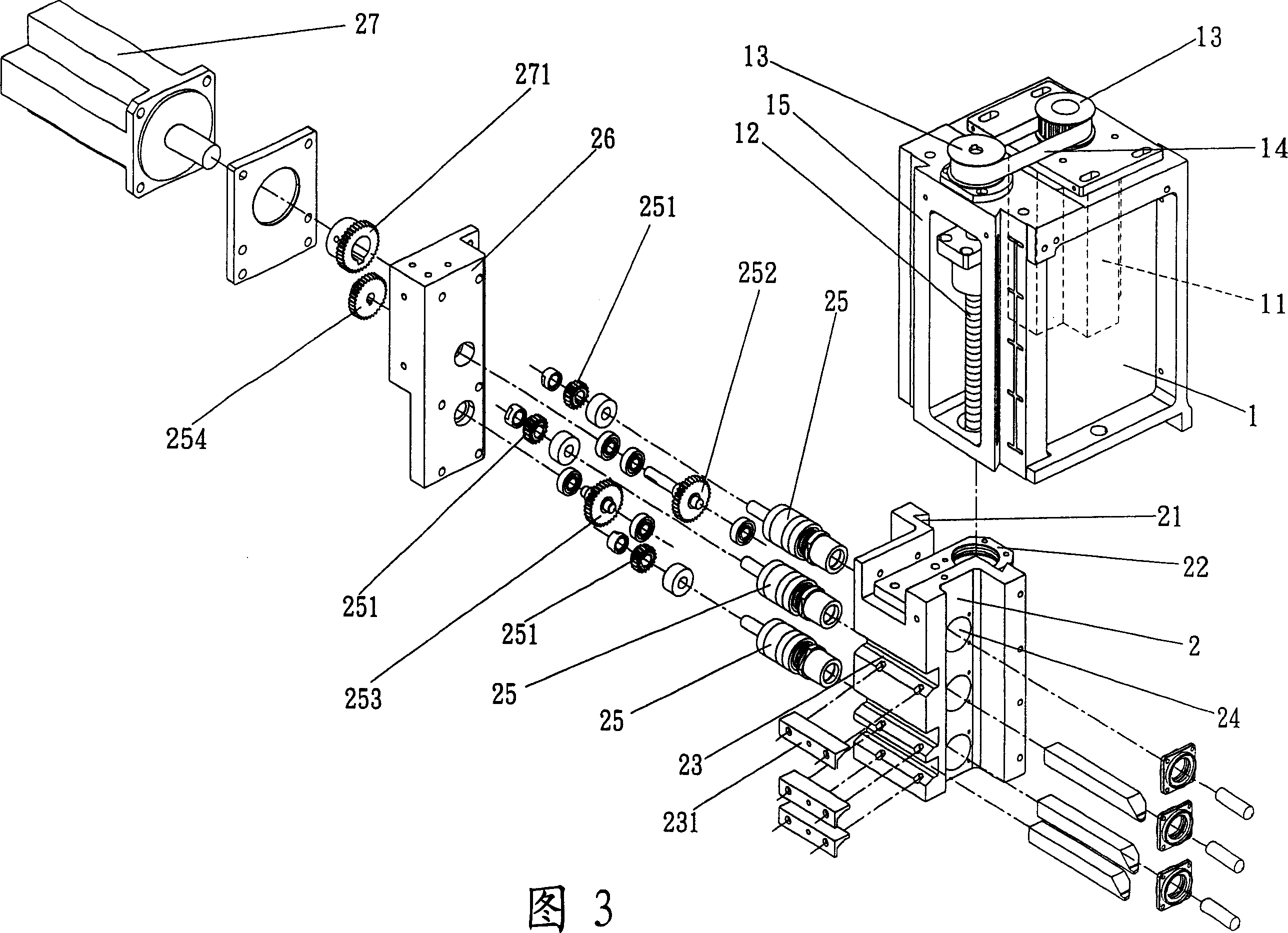

[0021] First please refer to Fig. 1 and Fig. 2, the CNC automatic processing machine of the present invention mainly includes machine table A, on which machine table A is provided with transverse sliding mechanism B, longitudinal sliding mechanism C, and a group of fixed and clampable Workpiece fixture D for high-speed rotation, and a group of milling device E (please refer to Figure 2) erected above the longitudinal sliding mechanism C; next, please cooperate with Figure 3 and Figure 4, the milling device E of the present invention mainly It includes a base 1 and a knife holder 2, wherein:

[0022] The base 1, as shown in Figure 3, is a rectangular inner hollow body, the base 1 is provided with a base motor 11 and a ball screw 12, and the gear 13 and the belt 14 on the top surface of the base 1 are used for transmission between the two. , and the base 1 is formed with a longitudinal dovetail slide rail 15 on the side facing the workpiece fixture D;

[0023] As shown in Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com