Stone crushing device for house building engineering

A technology for construction engineering and gravel, applied in solid separation, sieves, grids, etc., can solve the problems of increasing the waiting time of operators, single internal structure, slowing down the discharge speed, etc., to improve work efficiency and operation convenience. Simple and reasonable structure design, reducing the effect of working steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

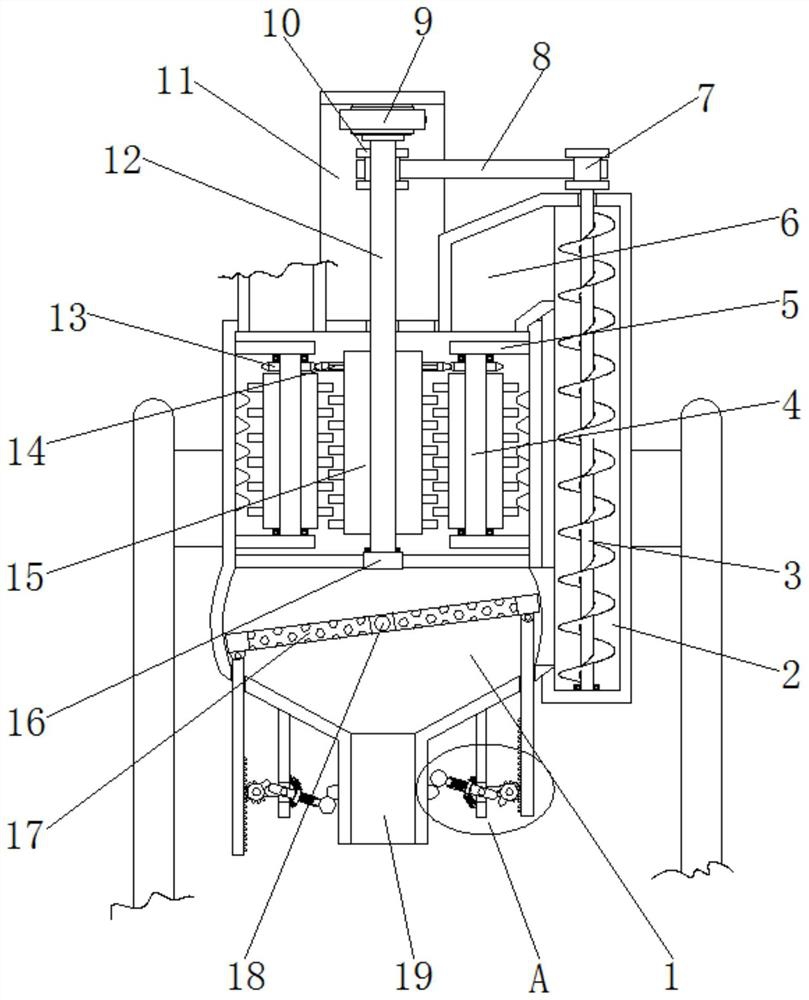

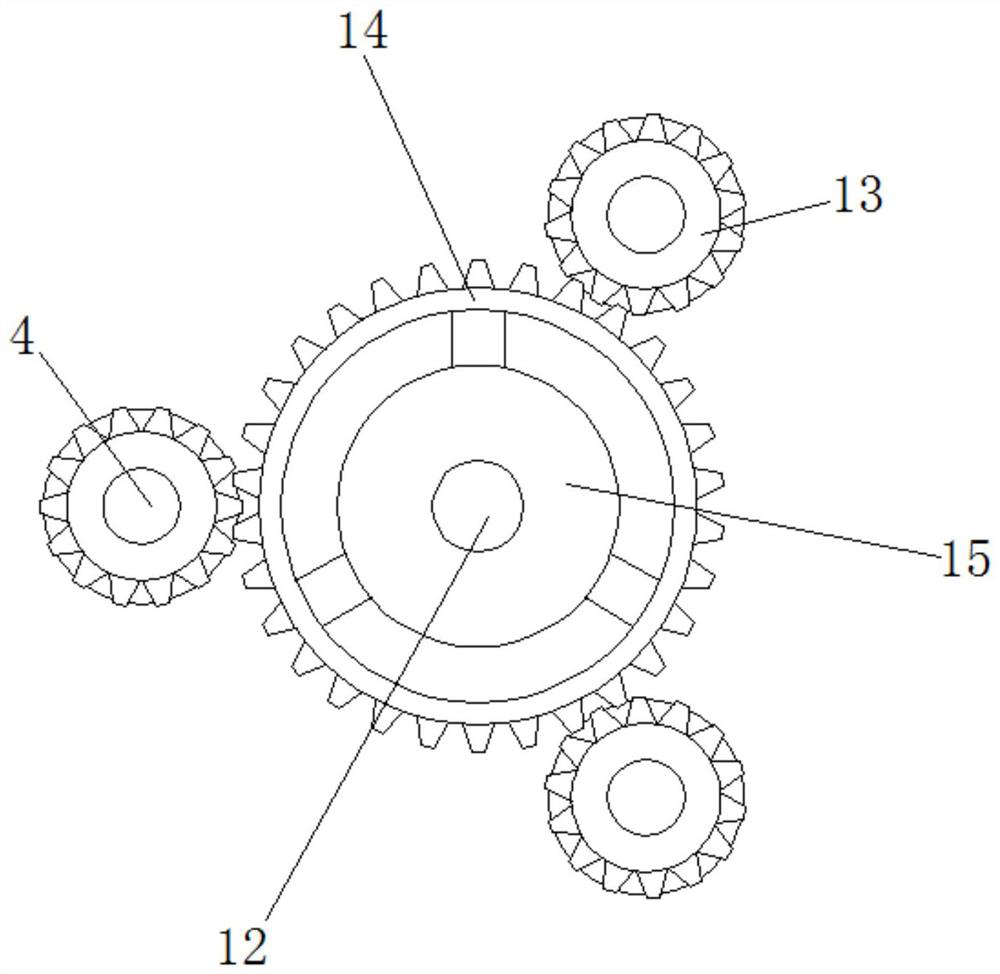

[0037] Example 1, such as figure 1 , 5 , 6 and 7, through the up and down movement of the connecting rod 28, the tooth block 27 can be driven to move up and down, and the meshing of the tooth block 27 and the half gear 29 can drive the half gear 29 to rotate, so that the half gear 29 Drive the toggle lever 30 to rotate, so that the toggle lever 30 presses the hinge lever 31. By pressing the hinge lever 31, it can be hinged and rotated, and then the impact ball 22 can be moved outside the fixed block 21. Make the fixed block 21 push the impact ball 22 and the slide bar 23 to slide inside the mounting groove 24 to compress the first spring 20. When the hinged rod 31 rotates to drive the impact ball 22 to break away from the surface of the fixed block 21, it can pass through the first spring 20. The elastic restoration force of a spring 20 drives the impact ball 22 and the above parts to perform restoration work, and at the same time, through the hinged rotation of the hinged ro...

Embodiment 2

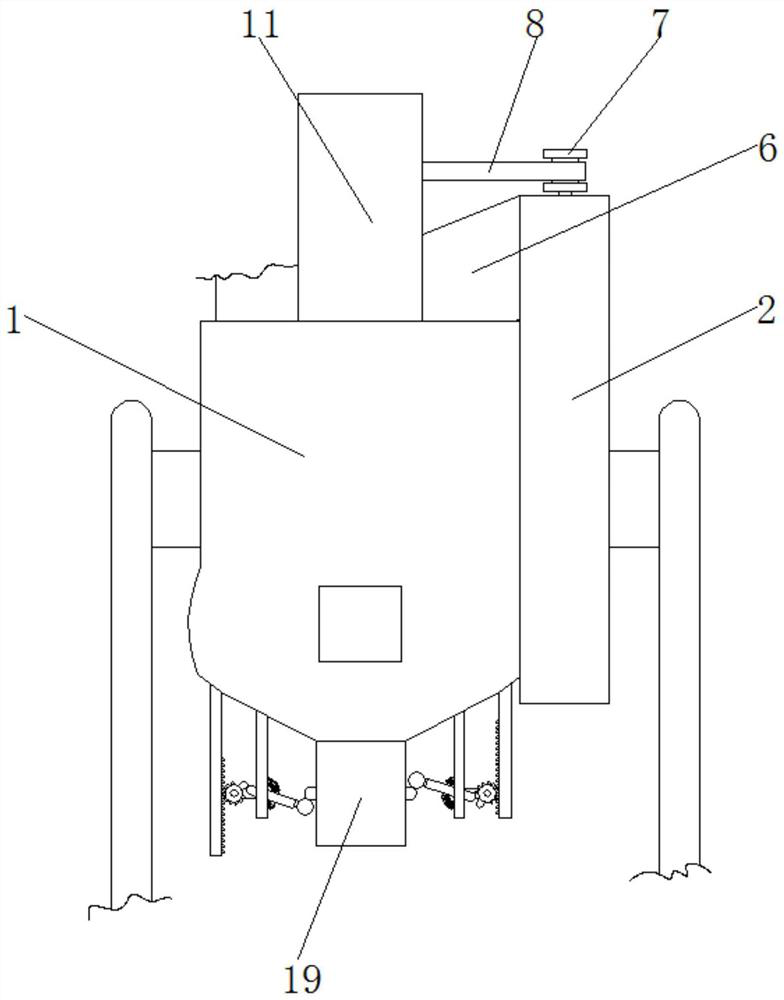

[0038] Example 2, such as figure 1 As shown, when the crushing is completed, the large gravel on the surface will roll down to the inside of the transmission bin 2 through the left and right rotation of the screen plate 17, and at the same time, the second pulley 10 can be driven to rotate by the first rotating rod 12, thereby The second pulley 10 drives the belt 8 to rotate, so that the belt 8 drives the first pulley 7 to rotate, and then the first pulley 7 drives the spiral transmission blade 3 to rotate, and the rotation of the spiral transmission blade 3 can rotate the inside of the transmission bin 2 Larger crushed stones are transported, and then enter the interior of the crushing bin 1 through the feed port 6, and then crushed again through the work of the second crushing roller 15 and the first crushing roller 4, so as to ensure that the crushed stones meet the standard Rate.

[0039] Working principle: When in use, the operator can put the stones to be broken into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com