A limestone pulverizing and humidity-adjusting processing system

A processing system, limestone technology, applied in grain processing, transportation and packaging, mixers with rotating stirring devices, etc., can solve problems such as screen blockage, affecting work efficiency, etc., to facilitate maintenance, improve work efficiency, and increase crushing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

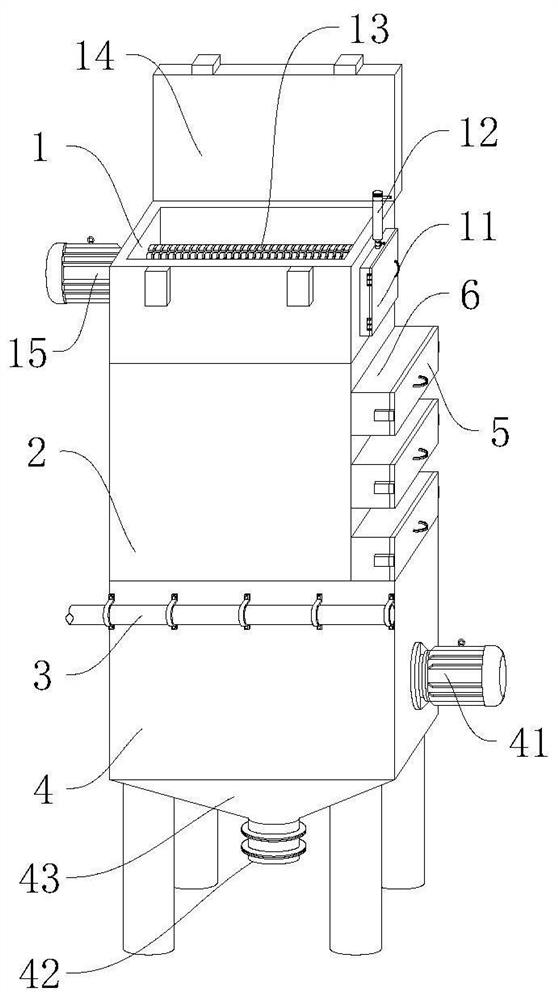

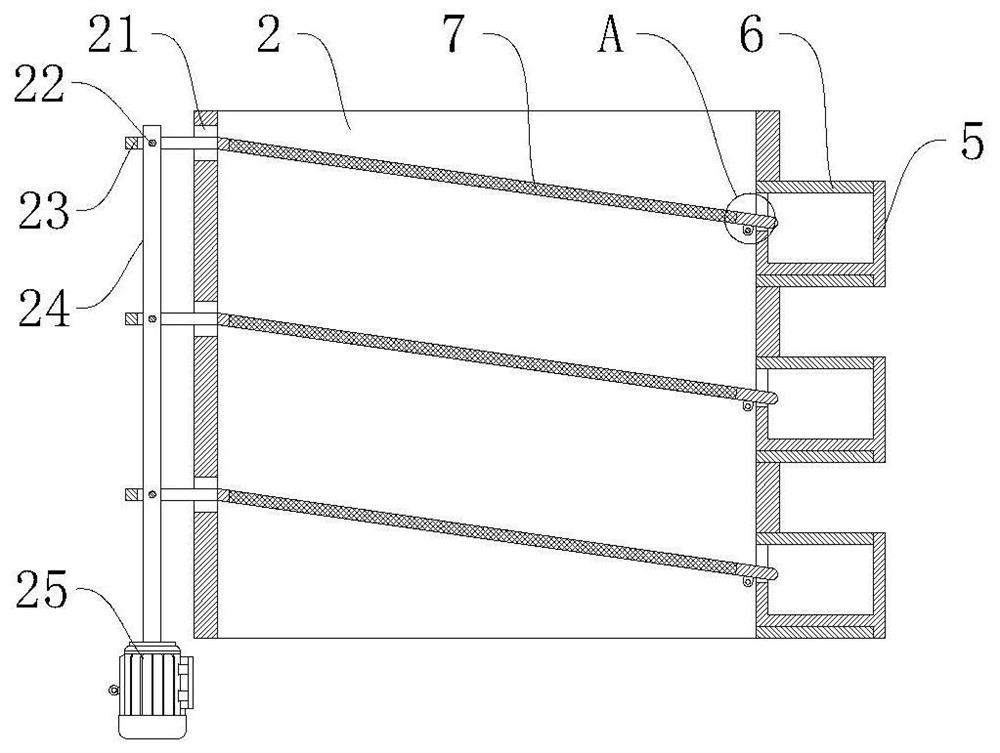

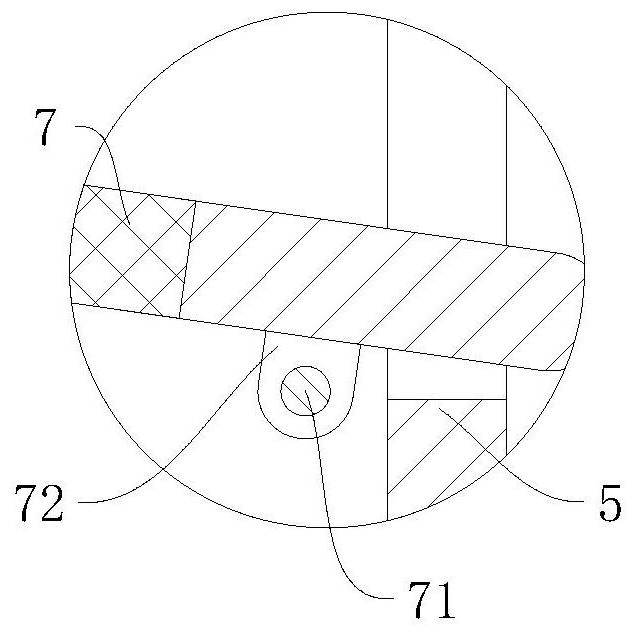

[0035] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS First, the circuits of the first motor 15, the vibrating machine 25 and the second motor 41 are turned on, and then the raw materials are put into the pulverizing square cylinder 1. After the putting is completed, the cover plate 14 is closed, and then the first motor is activated through the control switch. The motor 15, the first motor 15 drives one pulverizing roller cutter 13 to rotate, and uses the gear transmission box 11 to drive the other pulverizing roller cutter 13 to rotate, so that the two pulverizing roller cutters 13 rotate relative to each other, and then use the two relatively rotating pulverizing tools 13 to rotate. The roller cutter 13 pulverizes the raw materials, and the pulverized raw materials will fall into the connecting square 2 and the top screen plate 7, and the vibration machine 25 is activated by the control switch, and the vibration machine 25 drives the connecting rod 24 up and down Vibrate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com