Dust-proofing piece of linear sliding rail

A technology of linear slide rails and dust-proof sheets, which is applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve the problems of lack of convenience and the use of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

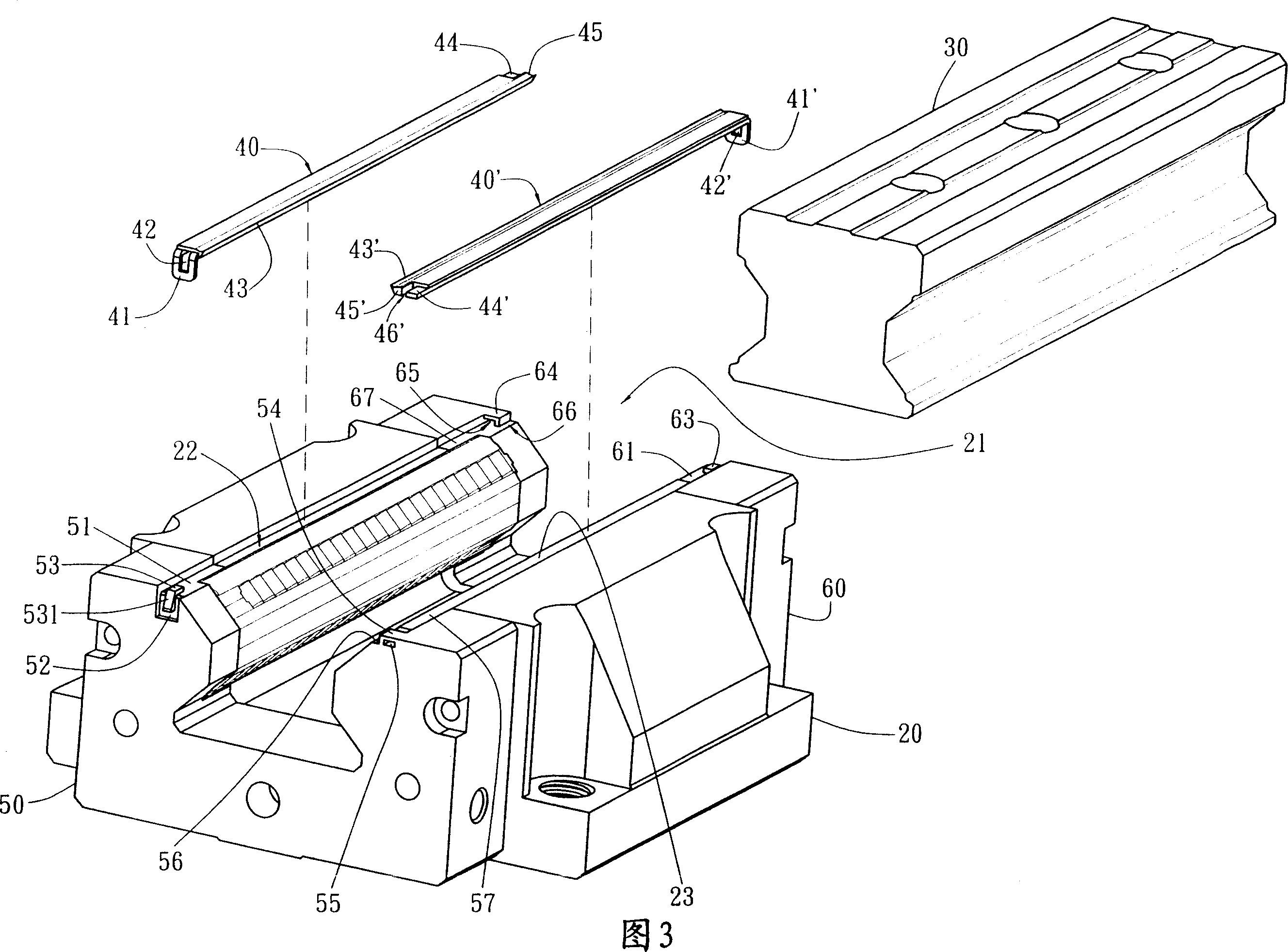

[0057] Please refer to Figs. 3 and 4, which is the first embodiment of the present invention. The dust-proof sheet 40 in this embodiment is in the shape of a long piece, and one end thereof forms a fastening portion that turns longitudinally and is roughly at a right angle. 41, the fastening part 41 is a piece, and a rectangular perforation 42 is set in the middle, and the rectangular perforation 42 slightly extends to the lateral end surface of the dust-proof sheet 40; the other end of the dust-proof sheet 40 is provided with an insertion part 44 and a The abutment portion 45, a slot (not shown in the figure) is provided between the insertion portion 44 and the abutment portion 45, and the insertion portion 44 is lower than the upper end surface of the dust-proof sheet 40; in addition, the dust-proof sheet The outer edge of the long side between the two ends of 40 forms a flange 43 that is slightly upward and gradually shrinks into a pointed cone; the dust-proof sheet 40 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com