Film against dazzle and reflection and polarized board and display device therewith

A technology of anti-reflection film and polarizing plate, which is applied in the direction of optics, optical elements, polarizing elements, etc., and can solve the problems of reduced yield and complicated forming methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

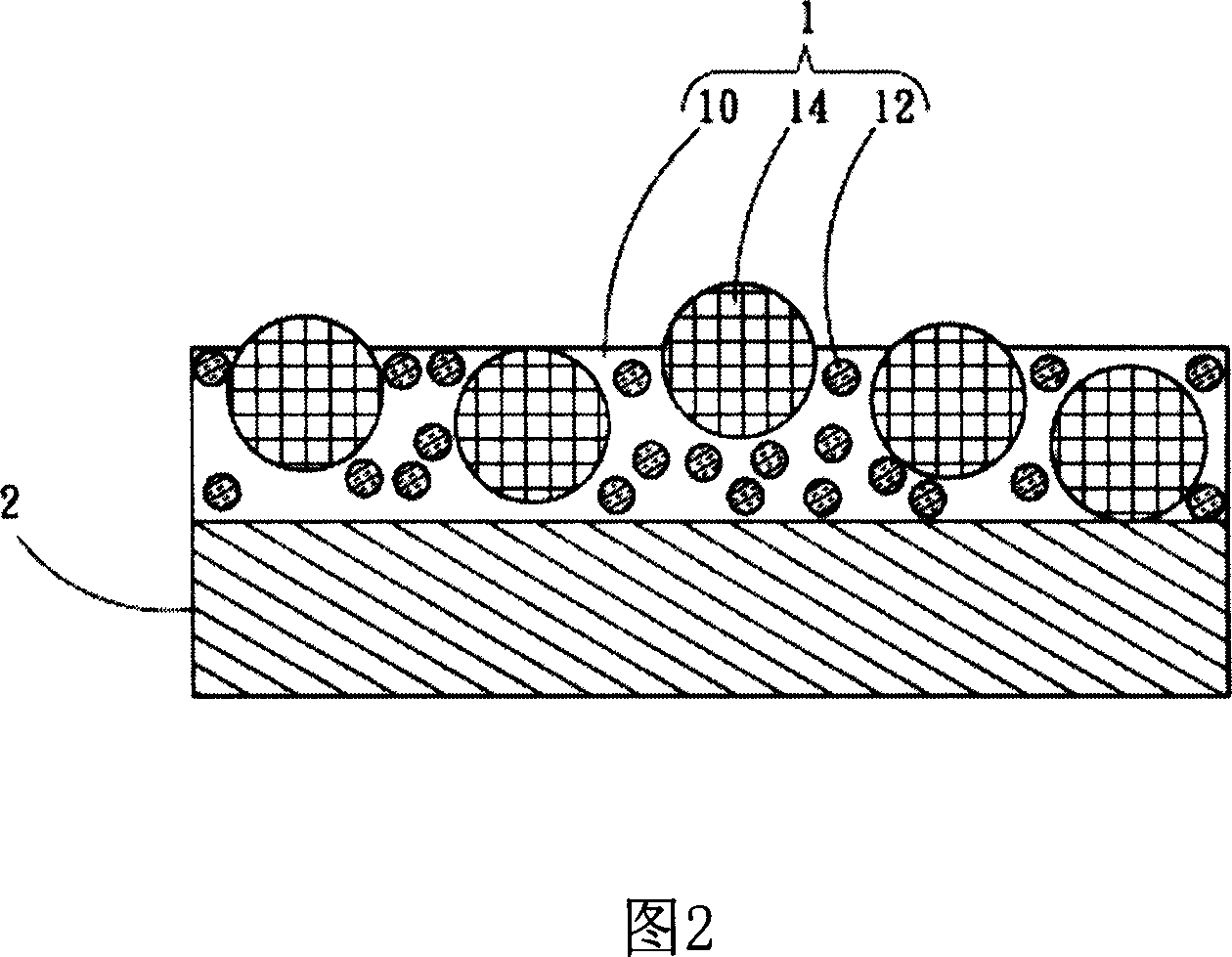

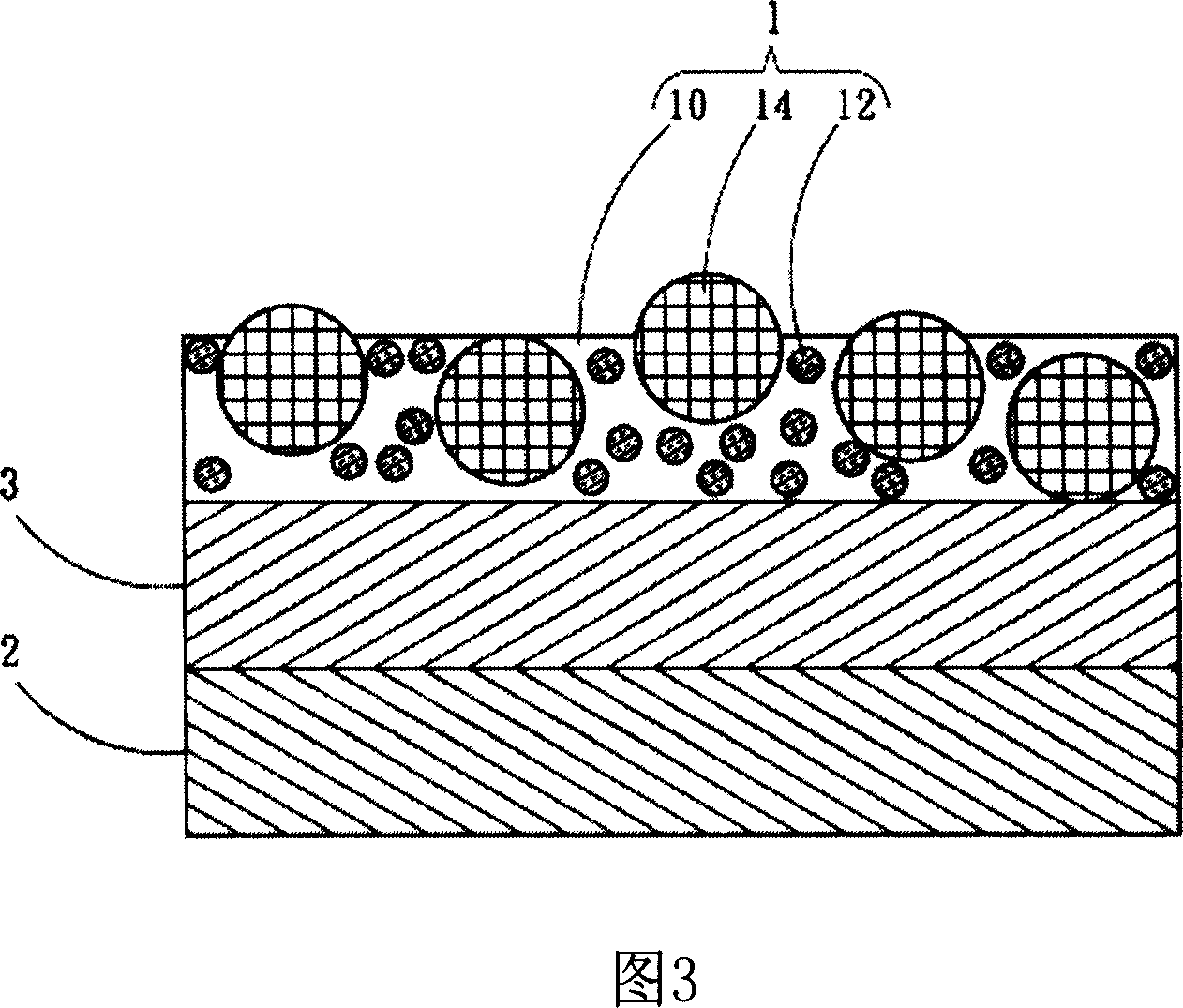

[0036] Please refer to FIG. 2 , the anti-glare and anti-reflection film 1 disclosed by the present invention is used to prevent glare when viewed. The anti-glare and anti-reflection film 1 includes a light-transmitting resin layer 10, a number of first light-transmitting particles 12 and a number of second light-transmitting particles 14. In use, the anti-glare and anti-reflection film 1 is coated on a substrate 2. Surface, so that the light emitted through the substrate 2 and the light incident on the substrate 2 can be diffused by the anti-glare anti-reflection film 1, so that the user will not feel glare when viewing, and increase visibility, and At the same time, it has the effect of reducing reflectivity. The anti-glare and anti-reflection film 1 preferably has a thickness of 6-10 microns.

[0037] The light-transmitting resin layer 10 is composed of a light-curing resin, which has good light penetration. After it is uniformly mixed with the first light-transmitting part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com