Yarn feeder

A yarn feeder and container technology, applied in thin material processing, textiles and papermaking, looms, etc., can solve problems such as tedious bonding process, impossible height adjustment of storage surface, and difficulty in leveling, etc., to improve self-locking The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will explain a so-called measuring yarn feeder of a jet loom. However, the measuring yarn feeder is only chosen as an example. Alternative reflector body fixing principles can be used in other types of yarn feeders, eg for other types of textile or weaving machines or similar.

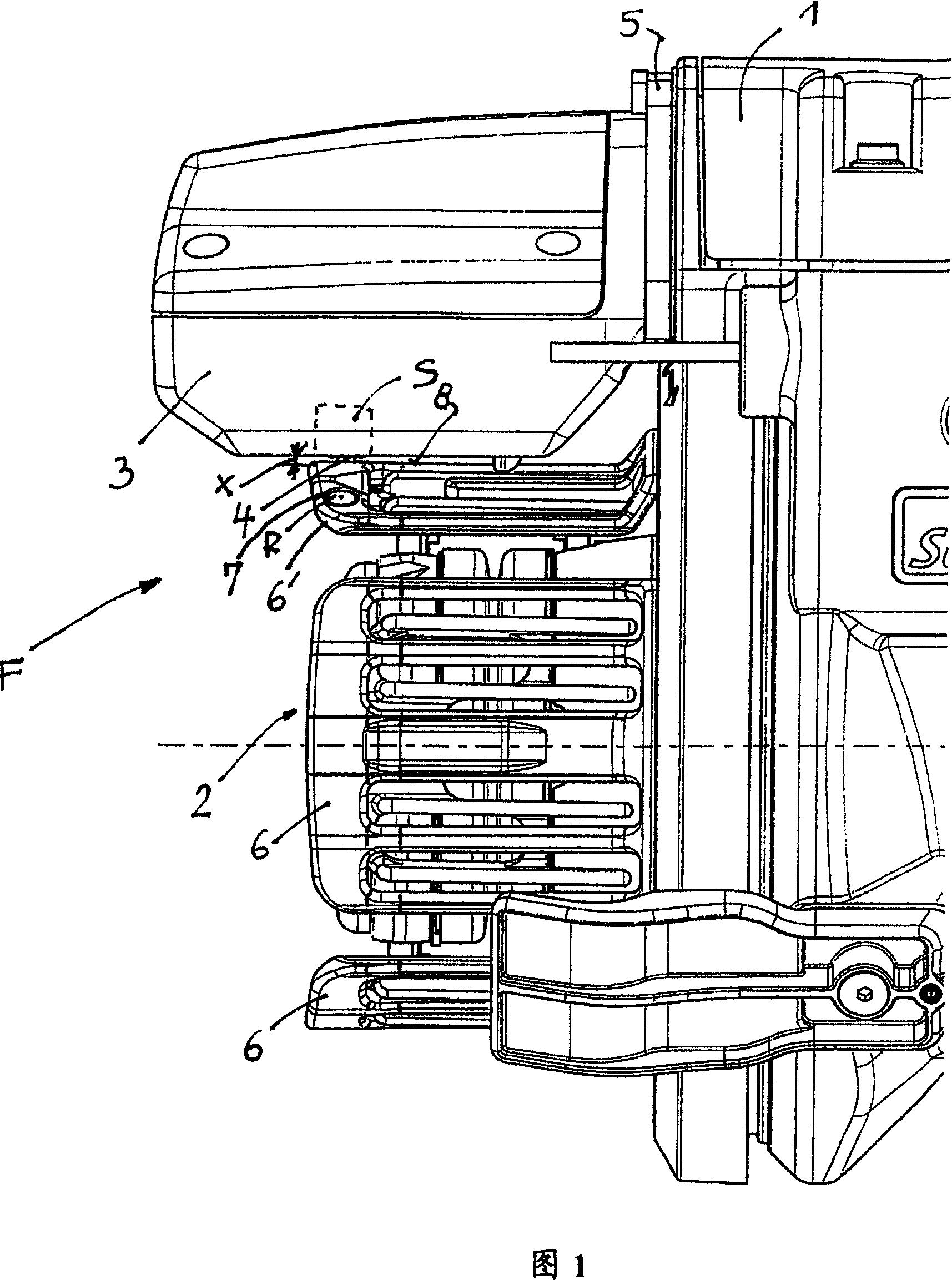

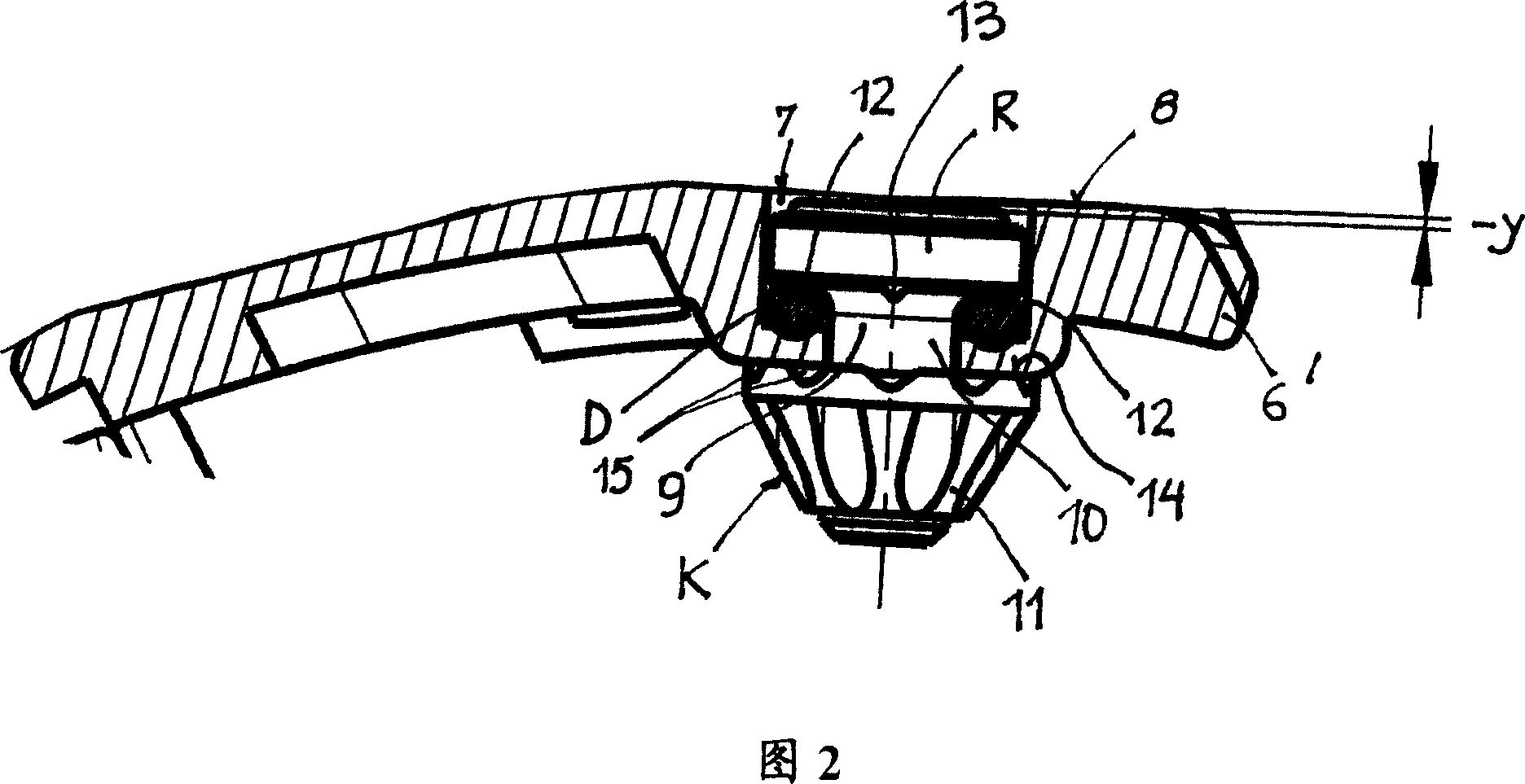

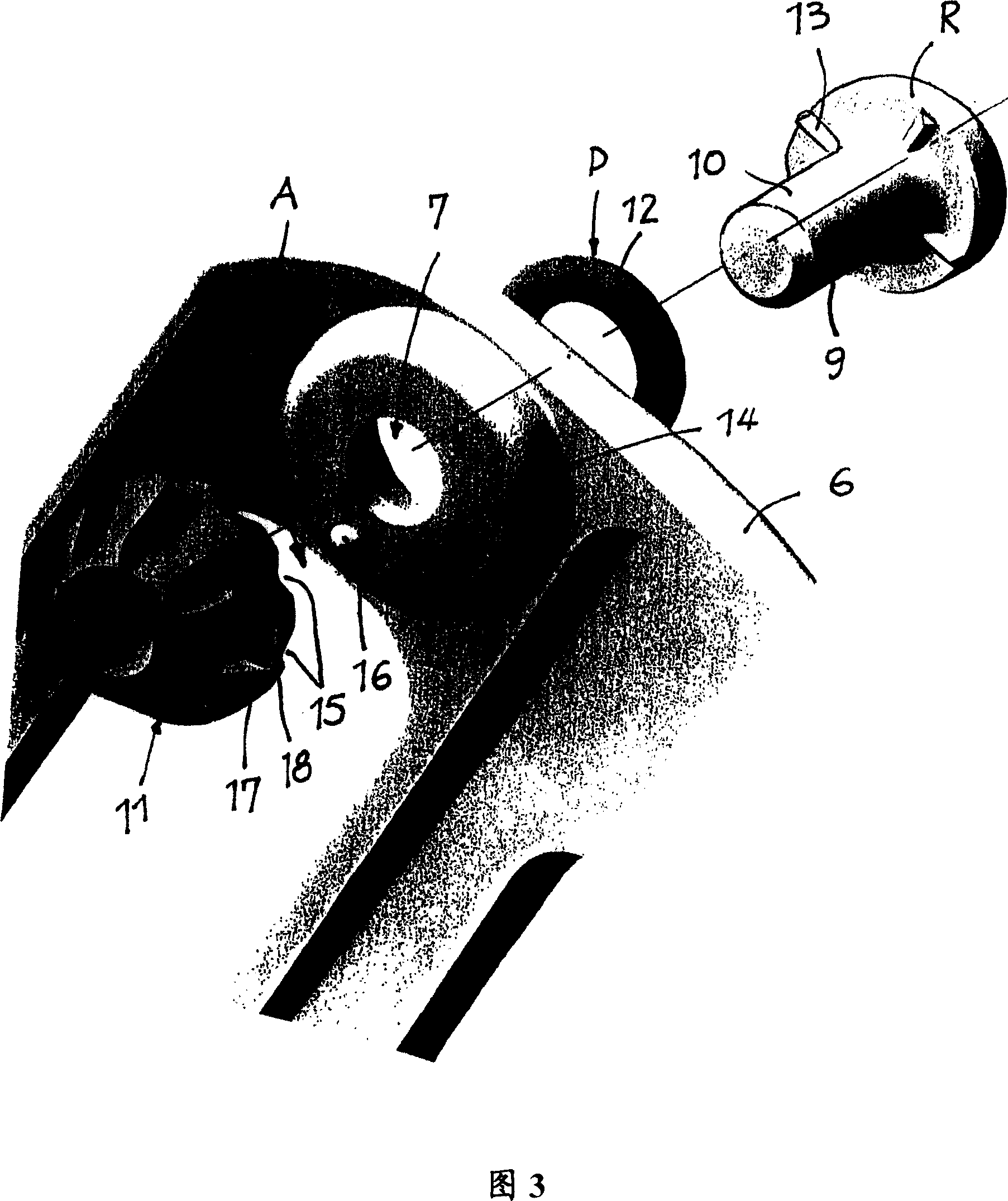

[0026] In FIG. 1 , the measuring yarn feeder comprises a housing 1 , a fixed storage body 2 and a brake housing 3 . The fixed storage volume 2 has a variable diameter. In order to adjust the radial position of the brake housing 3, once the predetermined diameter of the storage body 2 is adjusted, the brake housing 3 is adjustable in the radial direction relative to the axis of the storage body 2, so that in the storage of the storage drum 2 (storage drum) The yarn passing gap X between the surface 8 and the brake housing 3 usually has a certain width. This measurement is usually done with a gap gauge G (Figure 4).

[0027] The brake housing 3 comprises a pin-shaped brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com