A modular combined zipper head

A technology of module combination and zipper head, applied in the field of zipper head, can solve the problems of slow assembly speed of slider, inability to use slider, low production efficiency, etc., and achieve the effect of shortening production cycle, improving production efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

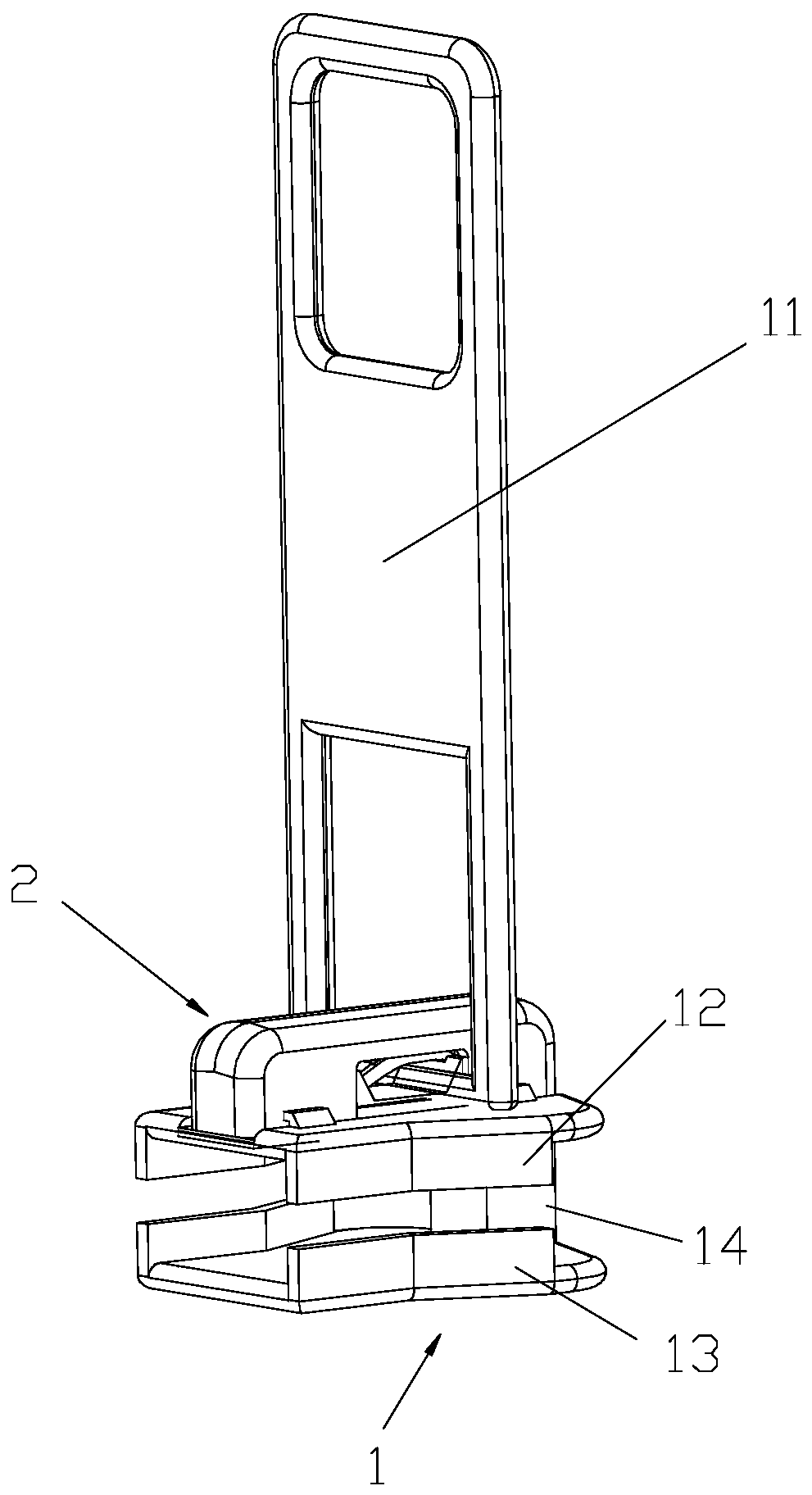

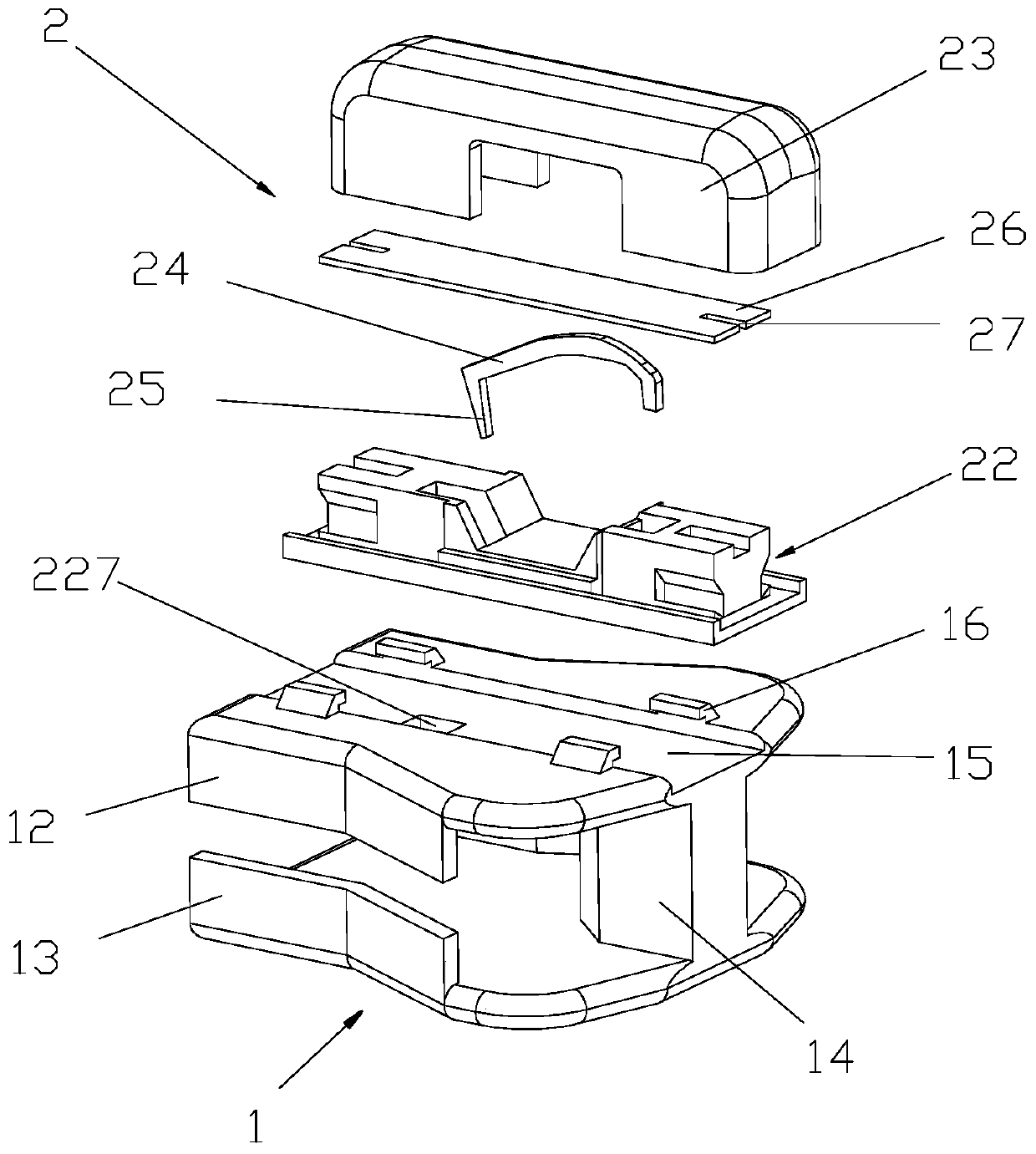

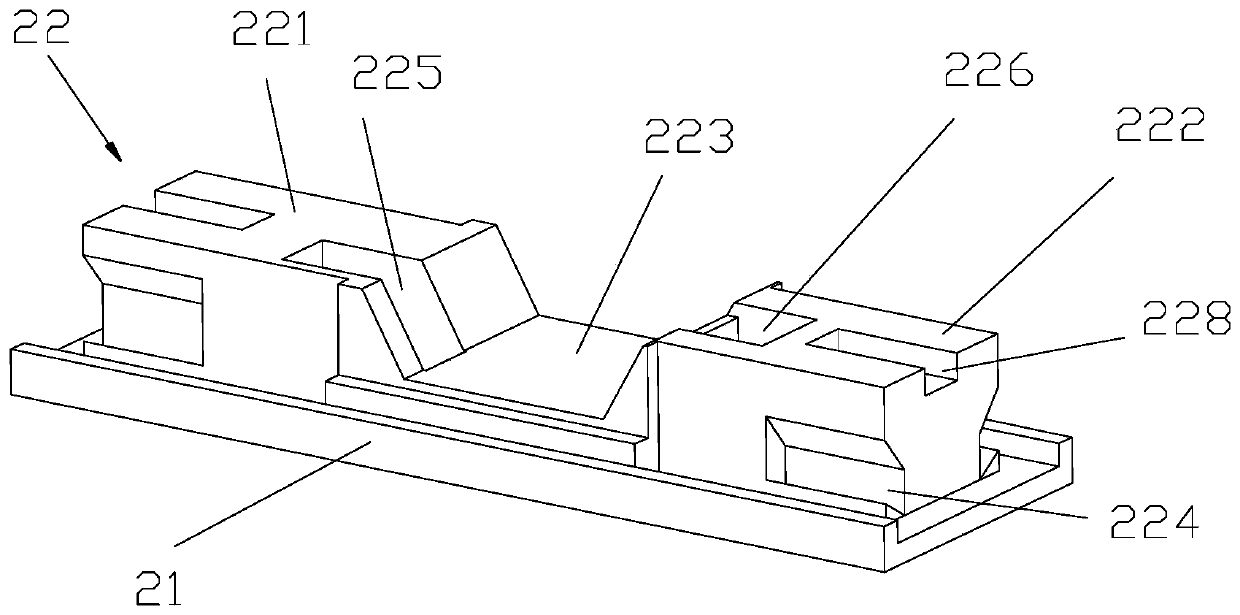

[0023] Such as Figure 1 to Figure 4 As shown, a modular zipper puller includes a slider body 1 and a pull tab 11, the slider body 1 includes an upper wing 12, a lower wing 13 and a support core 14, and the support core 14 connects the upper wing The piece 12 and the lower wing 13 are connected as a whole, and the top surface of the upper wing 12 is provided with a mounting groove 15 passing through the front or rear side of the slider body 1, and the mounting groove 15 is fitted with the nose mounting part 2, which can It is convenient to assemble and produce zipper pullers. At the same time, according to the needs of different customers, it is convenient to design different styles of pull nose installation parts 2, and then assemble them with the pull head body 1 in a later stage, which greatly improves production efficiency and shortens the production cycle. It can also digest the inventory very well, and the nose pull installation part 2, slider body 2, and pull piece 11 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com