Fire extinguishing system

A technology of fire extinguishing system and fire extinguishing medium, which is applied in fire rescue, fuel cell, life-saving equipment, etc., and can solve problems such as damage to fuel cell components, unsuitable electrical components, and insufficient function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

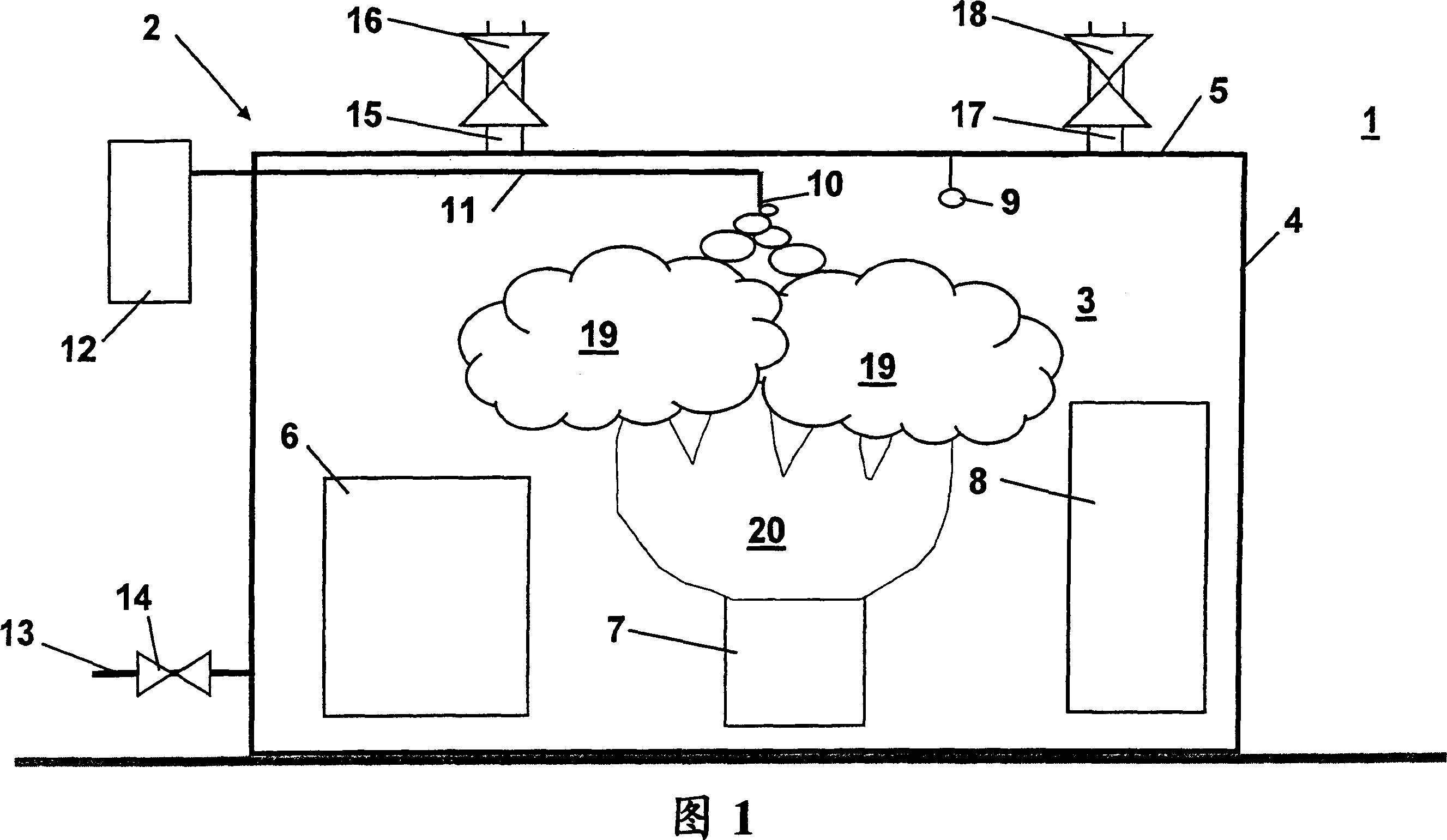

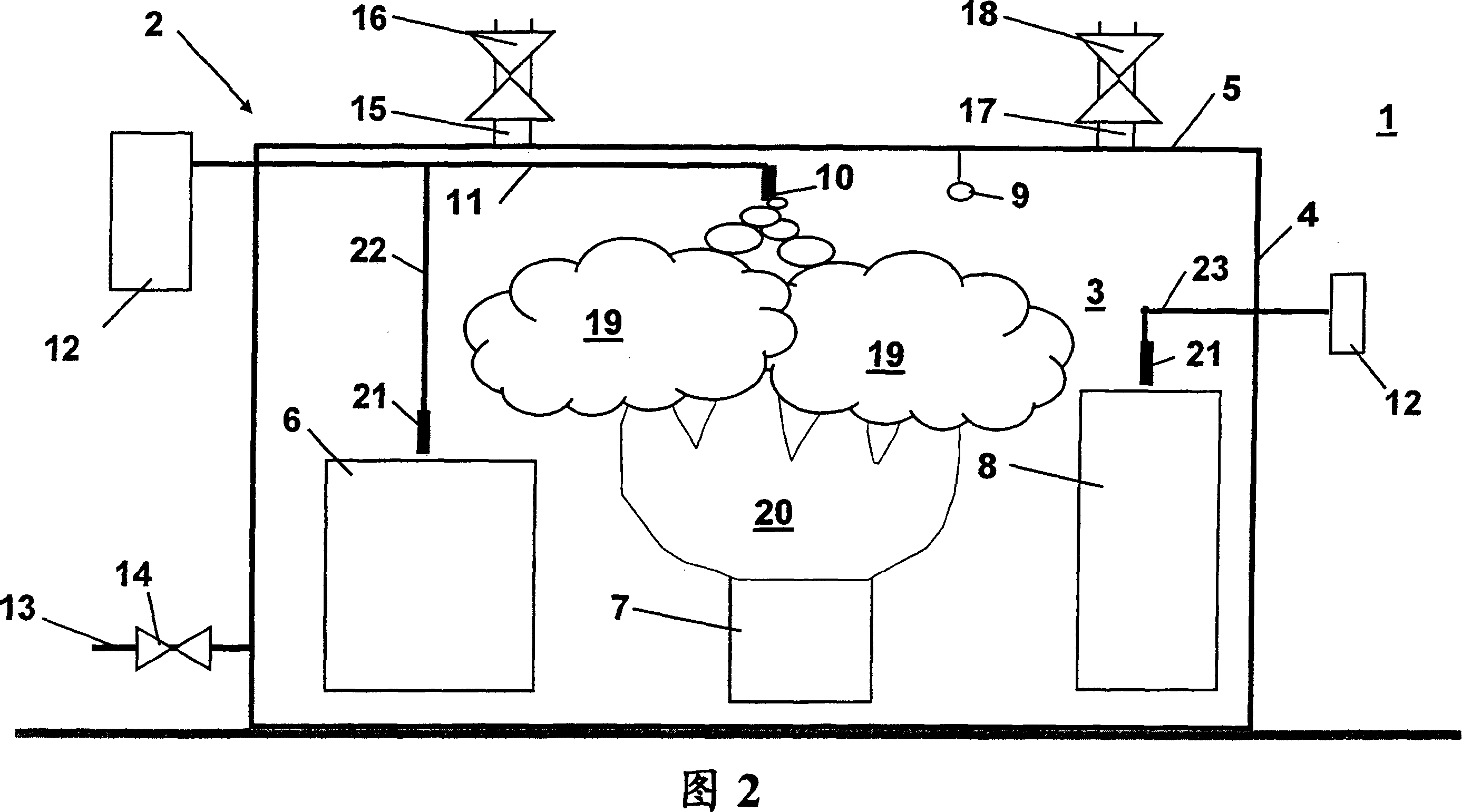

[0018] FIG. 1 shows a general view of a fuel cell assembly in the form of a fuel cell module 2 . The fuel cell module 2 is located in the engine room 1 of the marine vessel. In this embodiment, the fuel cell module 2 is enclosed in a container structure 3 provided with side walls 3 and a top wall 5 . The fuel cell module 2 includes a plurality of components. Figure 1 shows only some components generally as examples, such as fuel cell stack 6, auxiliary equipment 7 including fuel converters, heat exchangers, pumps, etc.; and power conditioner 8 including electrical converters and transformers.

[0019] The fuel cell module is provided with a flame detection sensor 9 inside the container. The flame detection sensor 9 preferably includes a smoke detector and a heat detector to ensure detection of a gas fire. Furthermore, the fuel cell module 2 includes internal nozzles 10 to release the extinguishing medium to the fuel cell module. The flame detection sensor 9 and the inner n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com