Hoisting slings specially for long steel rail

A technology of long rails and spreaders, which is applied in the directions of load hanging components, transportation and packaging, can solve the problems of inability to guarantee the safety of the transportation process, large deflection, etc., and achieves a simple structure of the spreader, improved stress conditions, and good rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

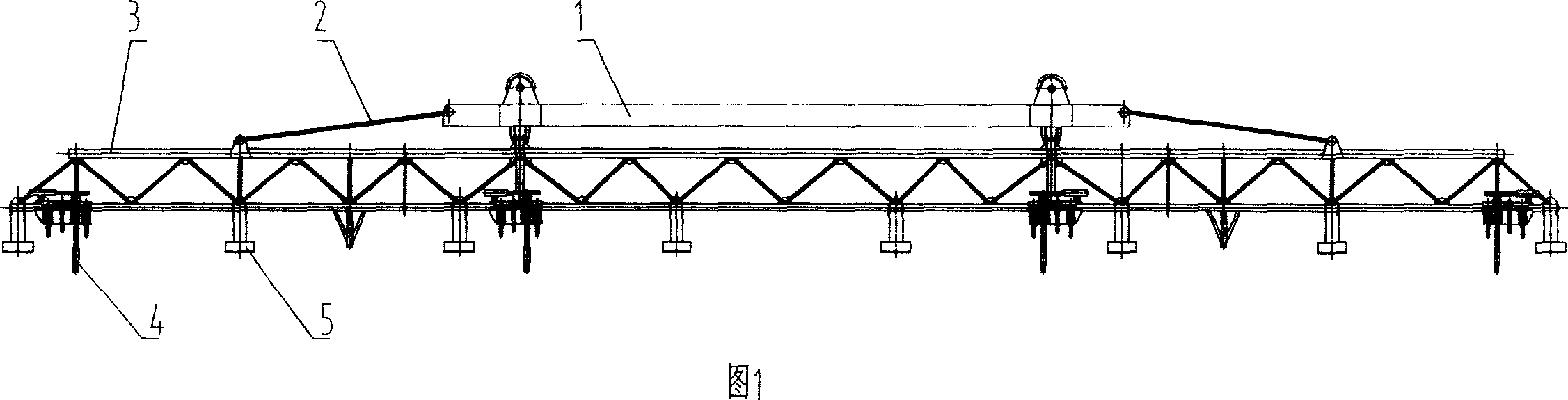

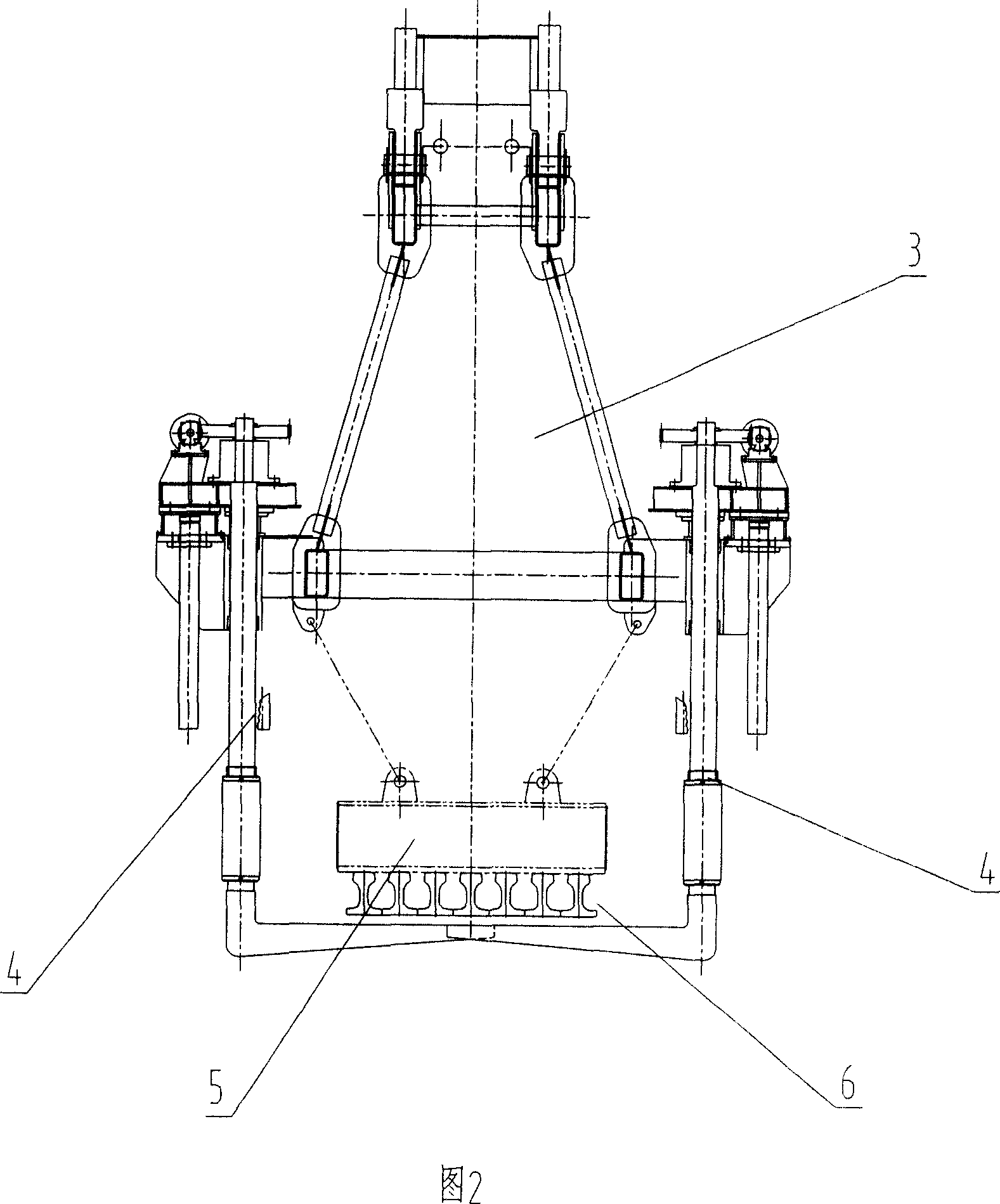

[0017] As shown in Figure 1 and Figure 2, a special lifting spreader for long rails. It includes hanging beams and two sets of pulleys installed on the hanging beams; the hanging beams are composed of upper hanging beams 1, adjustable pull rods 2, and lower hanging beams 3; connected by two pin shafts; the adjustable tie rods are connected at the ends of the upper and lower hanging beams. The upper hanging beam is a box beam structure with double suspension points, and the lower hanging beam is a truss structure with a trapezoidal cross section. The lower hanging beam is provided with some pairs of lifting rail protection devices 4, and several electromagnets 5 are housed, and the electromagnets are connected to the lower hanging beam with chains.

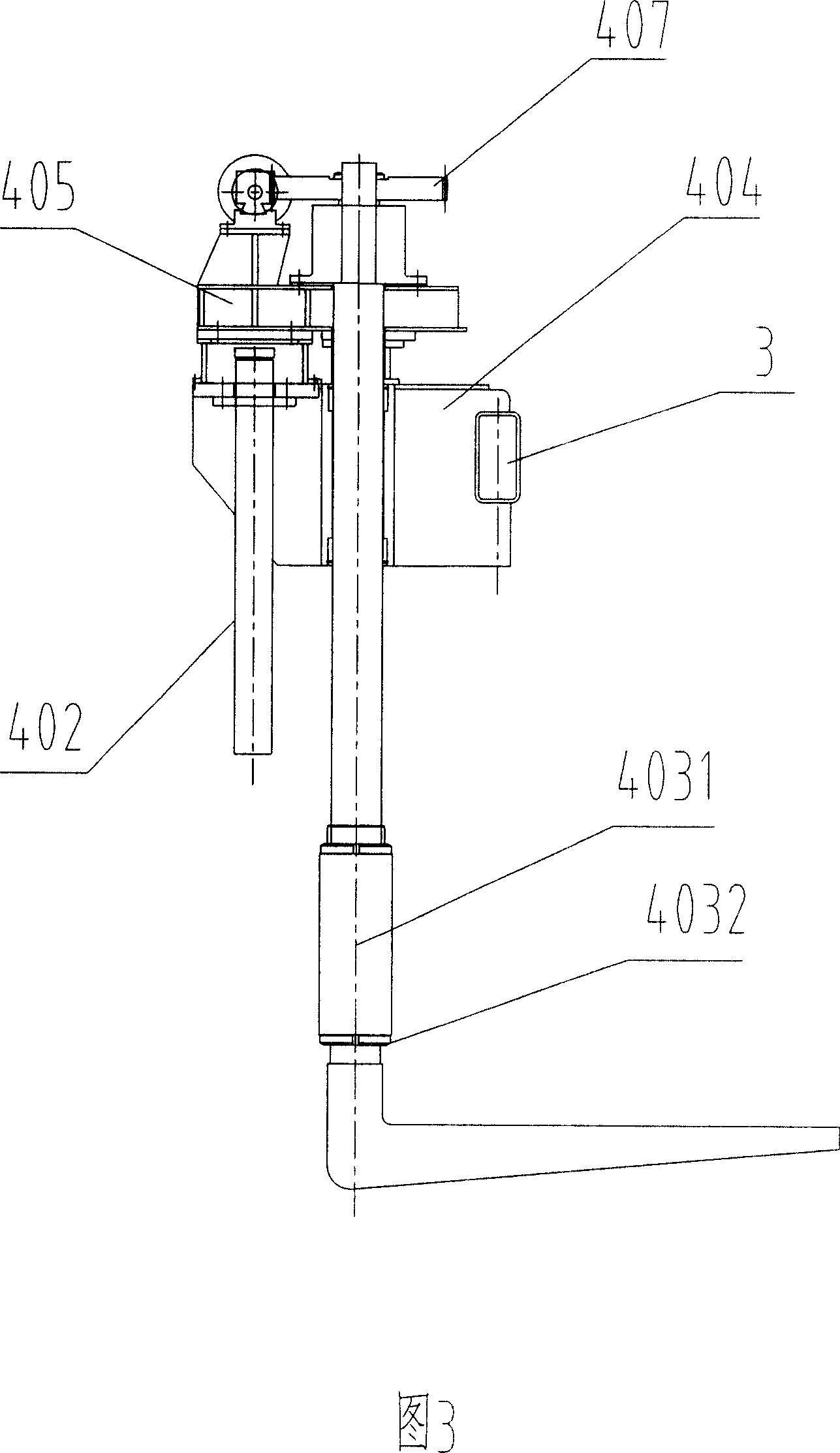

[0018] As shown in Figure 3 and Figure 4, the rail protection device. It includes a rotating pushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com