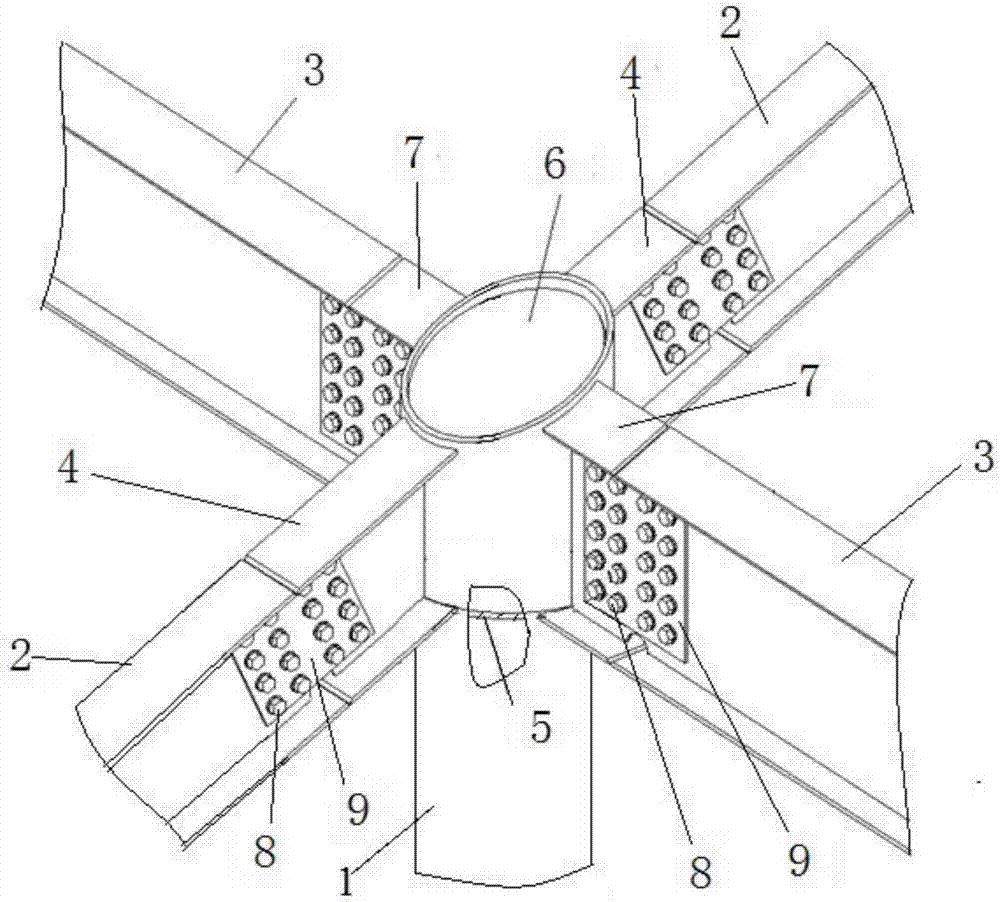

Column-beam intersection node structure of steel-structure antique-imitated gable and hip roof building roof

A technology of intersecting nodes and steel structures, which is applied in the direction of building construction and construction, can solve the problems of low degree of factory processing and difficulty in using steel structure systems, and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

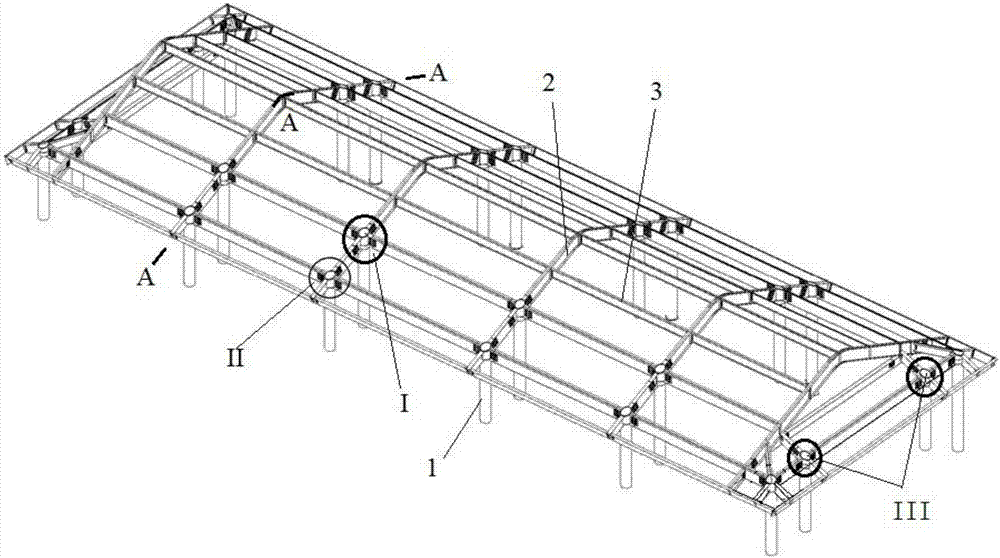

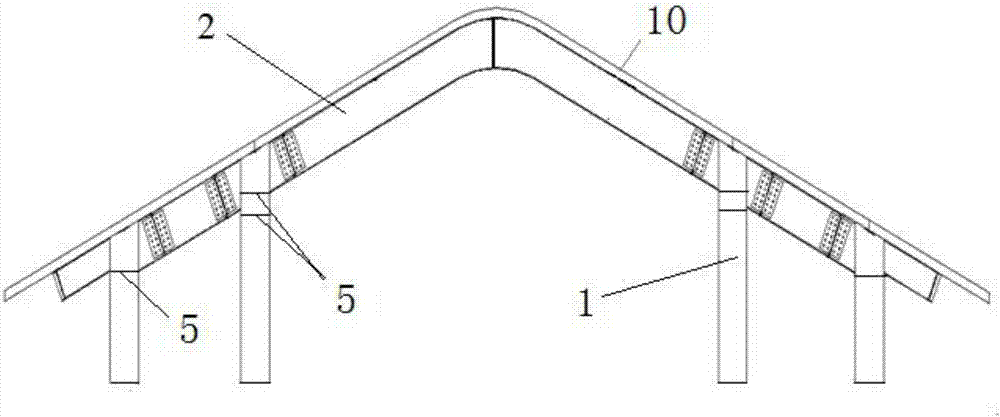

[0016] figure 1 , figure 2 Shown is the structural system of the steel structure imitating the Xieshan roof building, including two rows of round tube steel columns 1 located on both sides of the top line of the Xieshan roof, a group of mountain-shaped steel inclined beams 2 built on the top of the steel columns, and mountain-shaped steel columns. The inclined plane formed by the oblique beam is a group of steel beams 3 built horizontally on the mountain-shaped steel oblique beam. The two rows of circular tubular steel columns 1 on both sides of the top line of the Xieshan roof are respectively located, and the two columns of steel columns on the inner side are higher than the two columns of steel columns on the outer side; On the row of steel columns, the steel inclined beams on both sides meet at the top of the Xieshan roof.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com