Method for improving firmness of combination of dye-sensitized cell nanometer fibrous membrane and conductive glass

A dye-sensitized battery and nanofiber membrane technology, applied in electrolytic capacitors, circuits, capacitors, etc., can solve the problems of fiber structure and morphology damage, and achieve the effects of increasing bonding fastness, inhibiting cracking, and improving adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

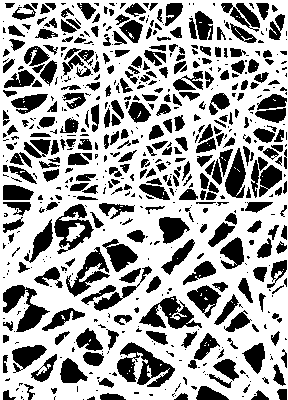

[0020] 0.68g PVAc was added to 4ml DMF organic solvent to form a solution with a mass percentage of 15wt.%, 1ml Triton X-100, 0.5ml HAc, and 1.36g TiP were added to the solution; after magnetic stirring for 8h, clarification, Viscous TiO 2 Precursor spin-coating solution, and spin-coat it on the FTO conductive glass cleaned by acetone and absolute ethanol ultrasonically with a spin-coater to form a one-layer spin-coating layer, and the spin-coater speed is 2000r min -1 , spin coating time is 30s.

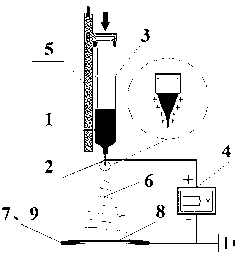

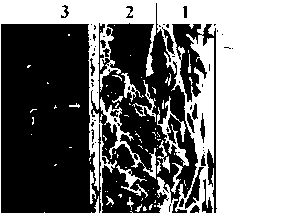

[0021] 0.52g PVAc was added to 4ml DMF to form a solution with a mass percentage of 11.5wt.%; 0.6 ml Triton X-100, 0.4ml HAc, and 1.04g TiP were added to the solution; a clarified TiO 2Precursor spinning solution 1, the precursor spinning solution 1 is loaded into the syringe 3 with spinneret 2, and a high voltage 4 of 16KV is added between the spinneret 2 and the receiving device 9, and the spinneret 2 to The distance of the receiving device 9 is 12cm, and the charged liquid dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com