Stacking device of sewing machine

A sewing machine and loading technology, which is applied in the field of stacking devices, can solve problems such as bumping, burden on the operator's waist and arms, and obstacles to taking out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

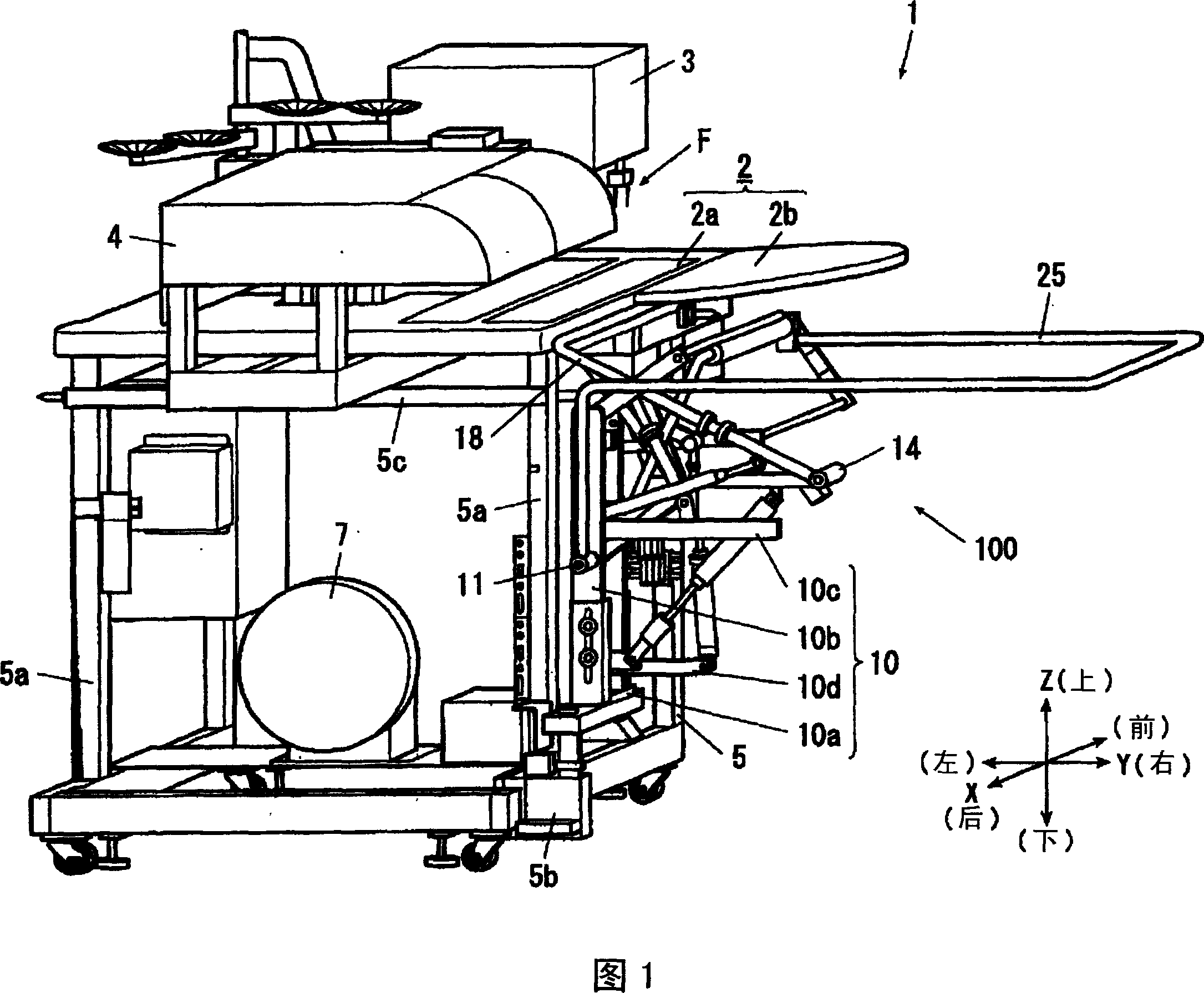

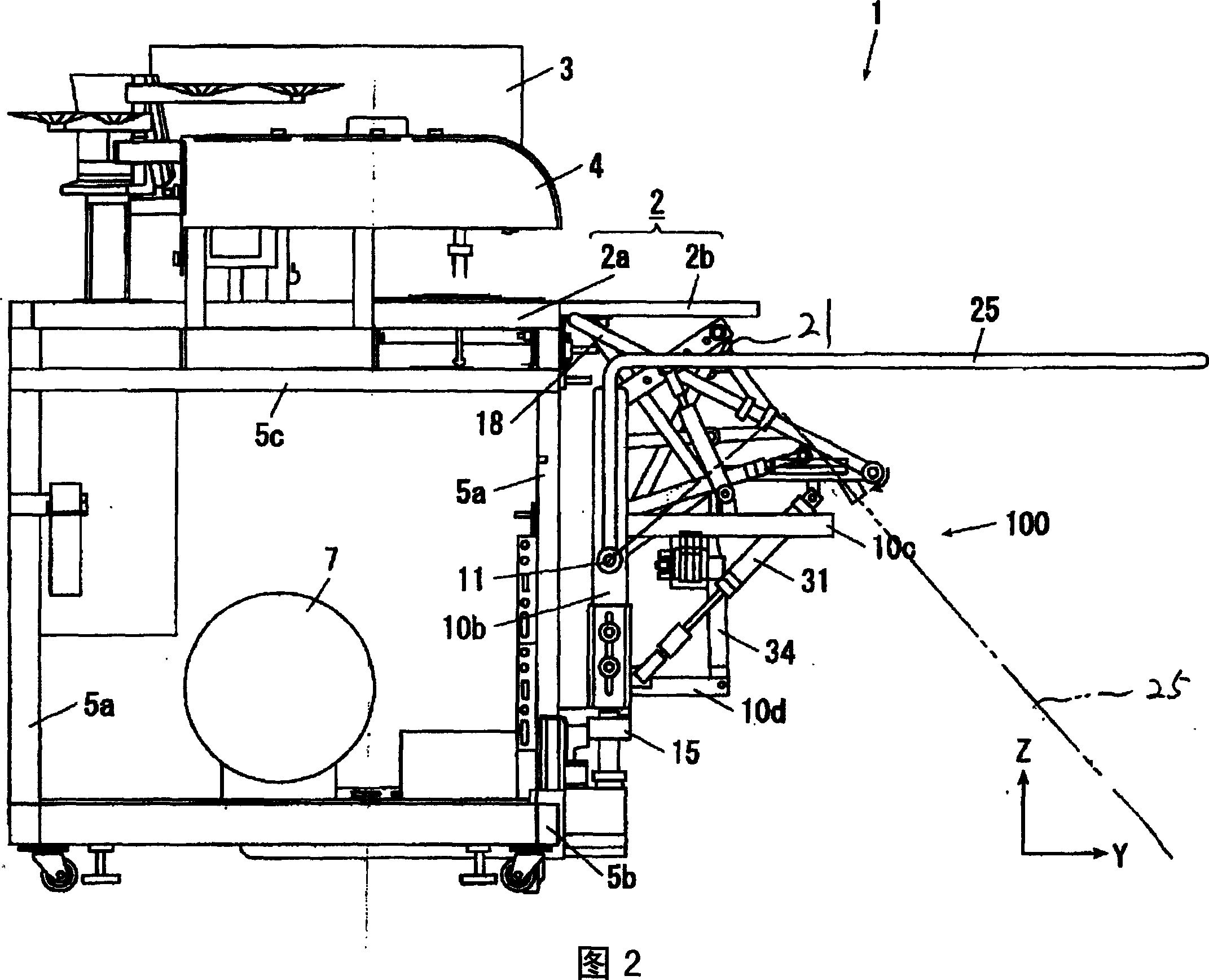

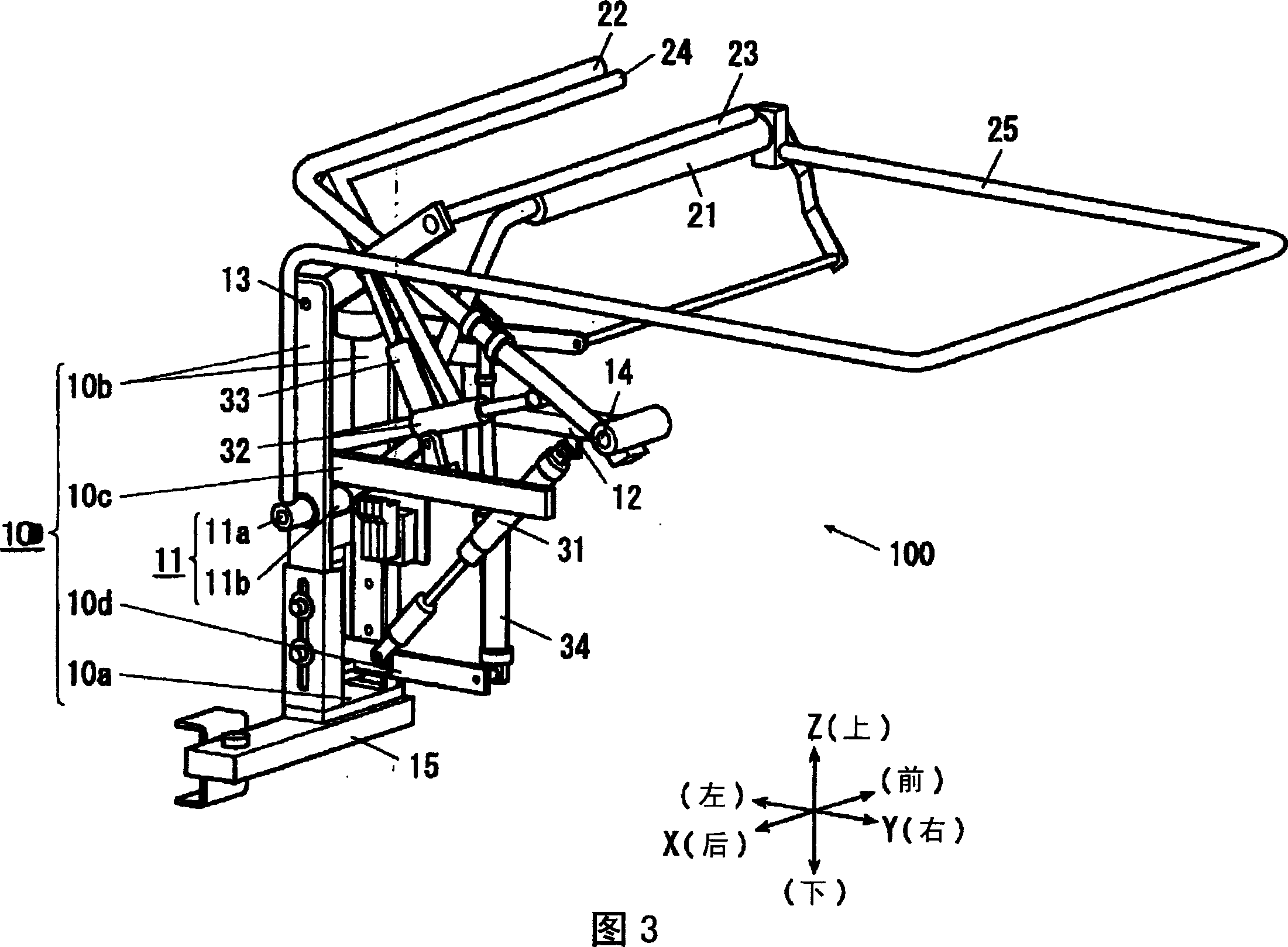

[0023] (Overall structure of the embodiment of the invention)

[0024] Hereinafter, an embodiment of the present invention will be described in detail with reference to FIGS. 1 to 6 . In this embodiment, as the stacking device of the sewing machine, for example, a stacking device mounted on an automatic panel sewing machine that performs panel sewing when forming a suit pocket or the like with two needles will be described as an example. In addition, the stacking device for sewing machines of the present invention is applicable not only to automatic panel sewing machines but also to other various sewing machines.

[0025] In addition, in the following description, the direction in which the sewing needle moves up and down described later is referred to as the Z-axis direction (up-and-down direction), and one direction perpendicular thereto, that is, the longitudinal direction of the sewing machine main body 3 described later, is referred to as the Y-axis direction. (left-righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com