Combined twistless compound pendulum

A combined and bending technology, applied in the field of compound pendulum, can solve problems such as large measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

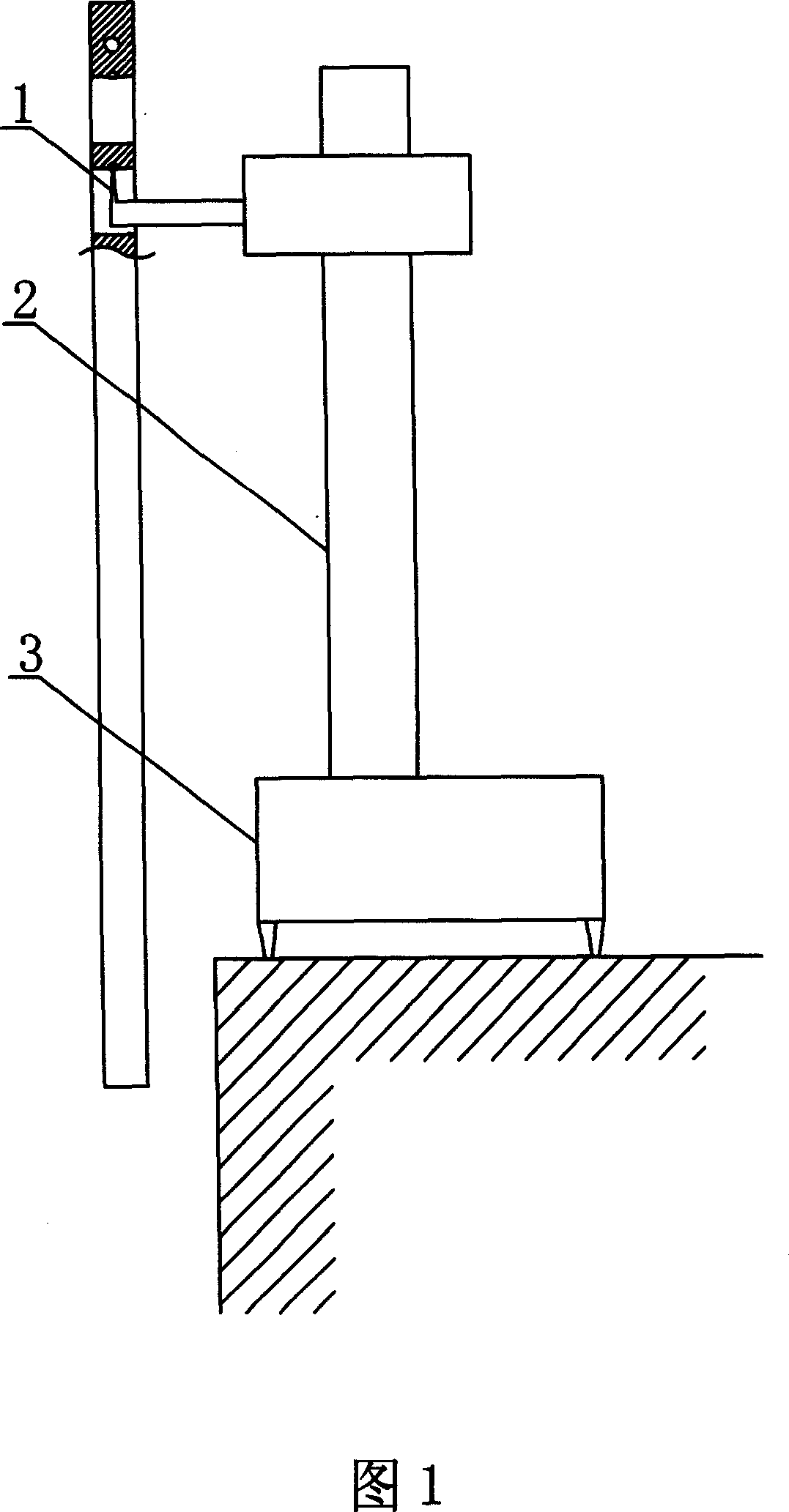

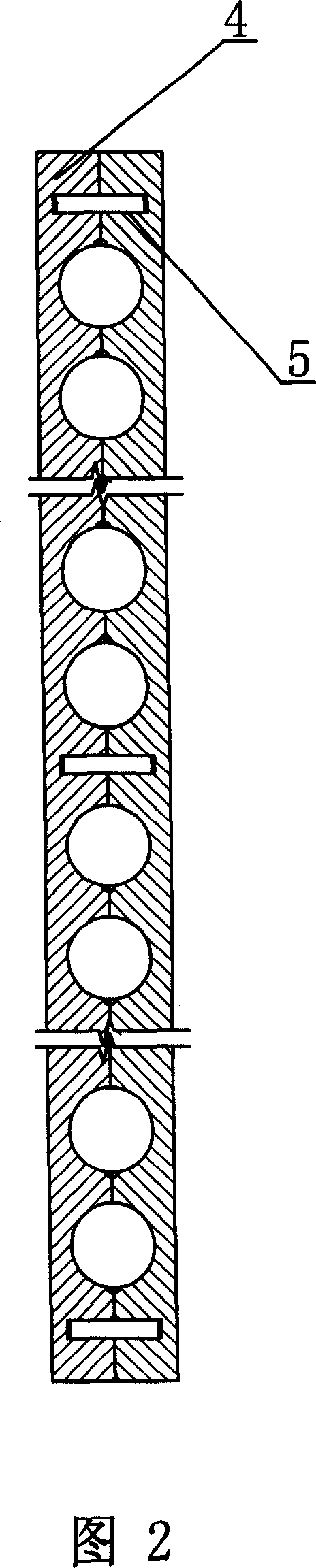

[0012] The complex pendulum pendulum bar (4) that has finished drilling operation is cut into two halves along the longitudinal centerline with a wire cutting machine tool, and then on each concave semi-cylindrical surface of the two halves respectively by the suspension end. Open a gap at the midpoint of one side edge, the width of the gap is 1.5mm, and the depth is 1mm, then use pins (5) to combine the sections of the two halves into a whole, and fix the bent support cone (1) on the Above the compound pendulum bracket (2), the support part of the bent support cone (1) is conical, the diameter of the bottom surface of the cone is 3 mm, and the length is 8 mm. When the swing rod (4) is suspended on the bent support cone (1) Finally, the conical apex of the bent support cone is in the depression at the top of the fork (4) hole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com