Electrical current measurements at head-disk interface

A current measuring device and current technology, applied in the protection measures of the magnetic head, aligning the magnetic tracks on the magnetic disk, recording information on the magnetic disk, etc., can solve the problems of interference measurement accuracy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

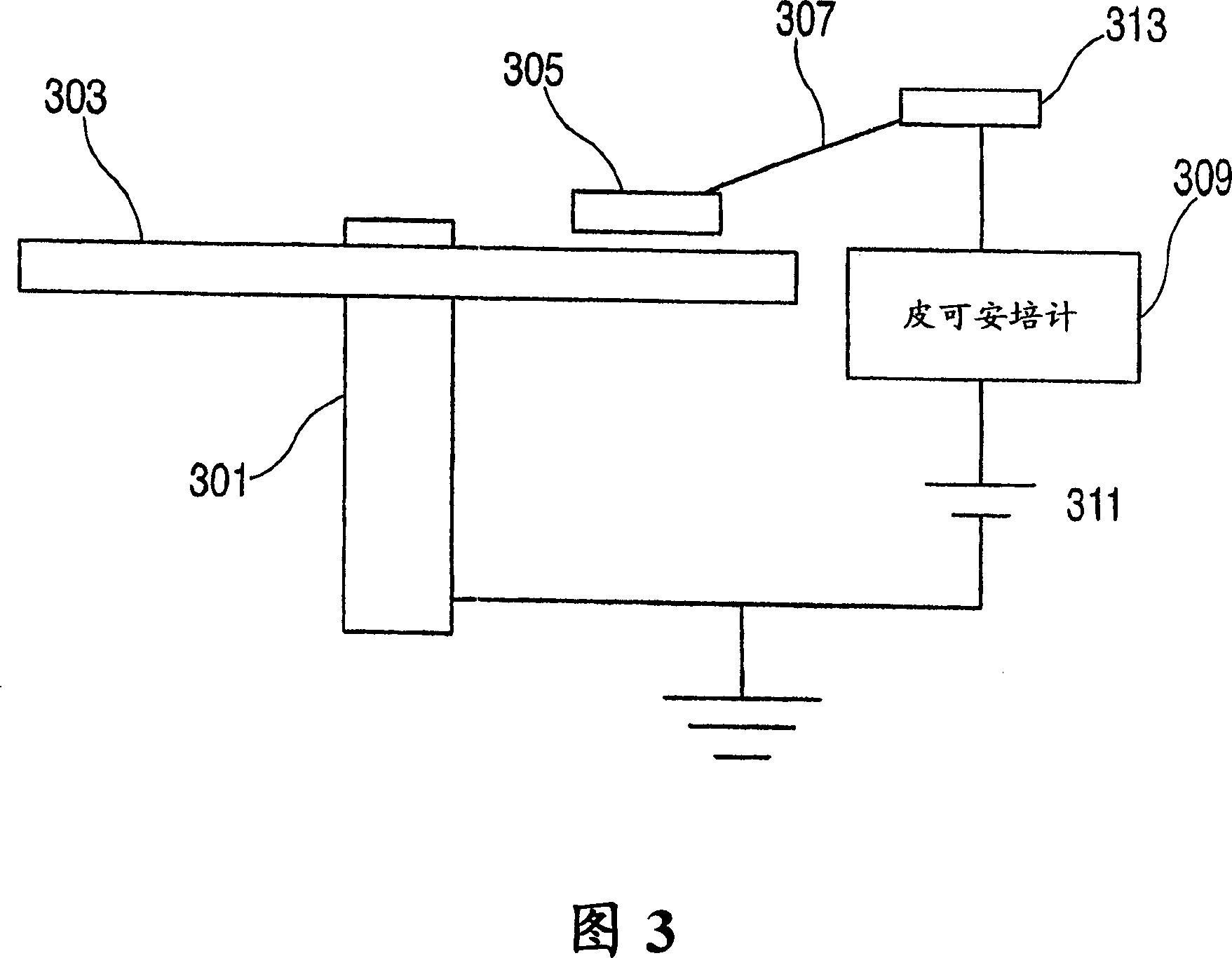

[0025]Referring to Figure 3, an apparatus for measuring current at the head-disk interface is shown. Like a conventional disk drive, a magnetic recording medium (such as a magnetic recording disk 303 ) rotating around a rotating shaft 301 is provided. In this example, the disk 303 is clamped to the shaft 301 and electrically grounded. A head, such as magnetic recording head 305, is provided with an air bearing surface to allow it to float over the moving disk surface. A current measuring device is provided, such as a picoammeter (eg, model 6487 picoammeter / voltage source manufactured by Keithley Instruments, Cleveland, Ohio).

[0026] In a first embodiment of the present invention, the head gimbal assembly (HGA, including the head 305 and its supporting flexures) is electrically isolated from ground. The ammeter 309 is connected to a contact 313 which is electrically connected to the magnetic recording head on the suspension 307 . As seen in Figure 3, if the HGA is electric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com