Variable watt density layered heater

A technology of power density and heater, applied in the direction of ohmic resistance heating, electric heating device, high current matching device, etc., can solve the problem of low power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

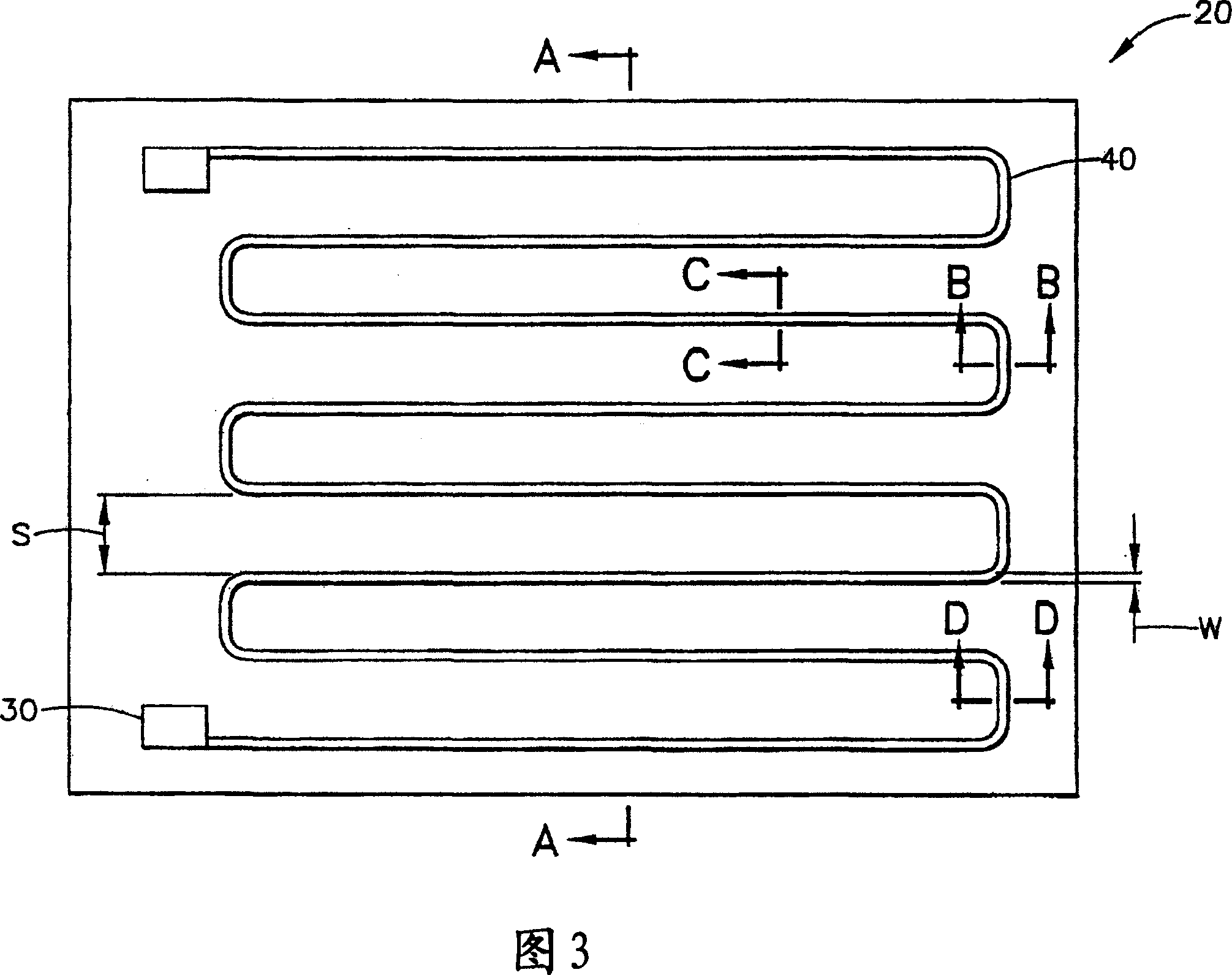

[0035] The following description of preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention and its application or uses.

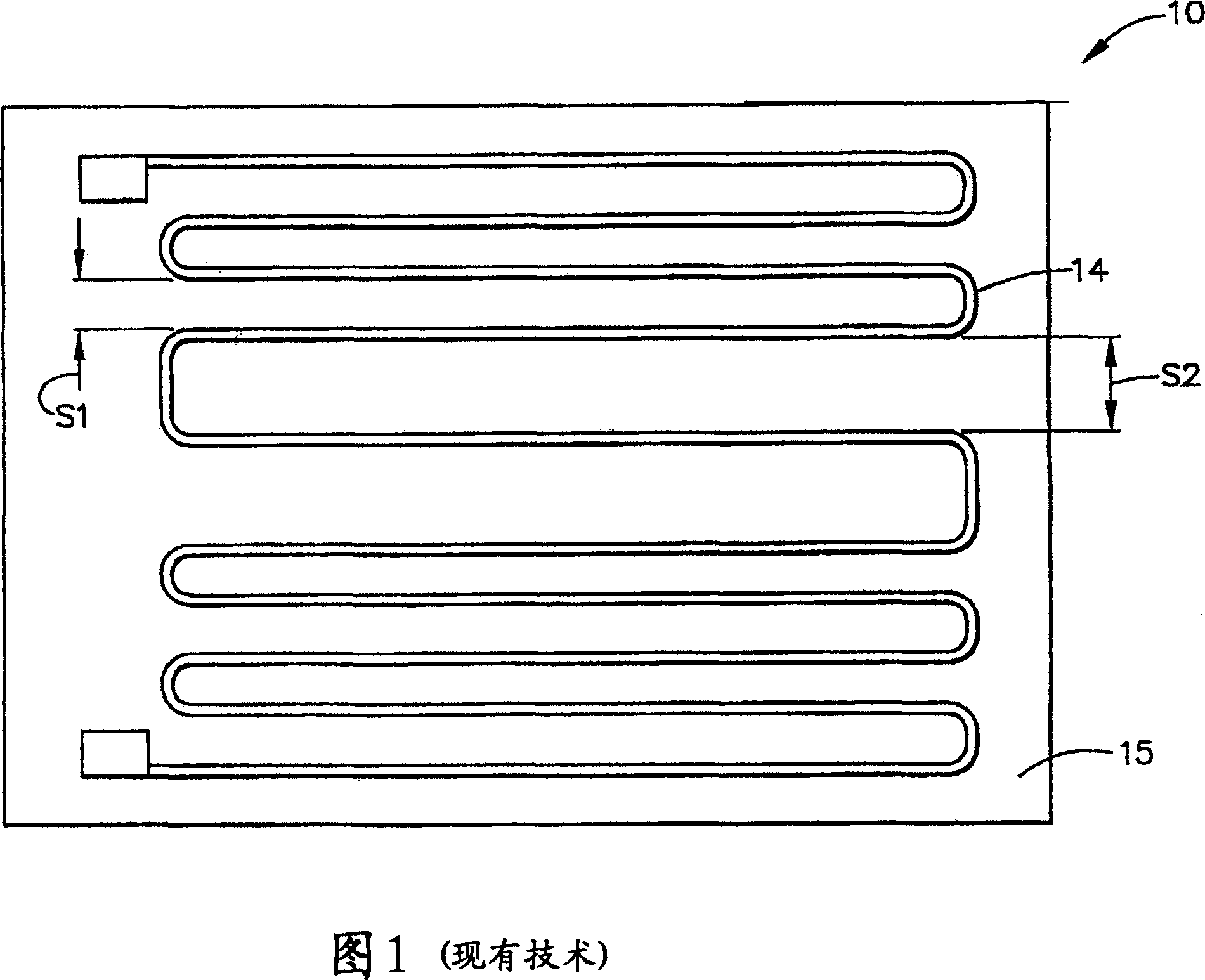

[0036] Referring to Figures 1 and 2, two (2) prior art heater systems 10 and 12 that provide variable watt density are shown. Prior art heater systems 10 and 12 each include resistive circuit patterns 14 and 16, respectively, which provide the required heat to the heated part or device. Generally, the resistive circuit pattern 14 in FIG. 1 is formed on a substrate 15 and includes a variable pitch (eg, S1 and S2) as shown to provide variable power density as desired. In the area of S1, the spacing is closer and thus the power density is higher. Conversely, in the region of S2, the spacing is wider and thus the power density is lower.

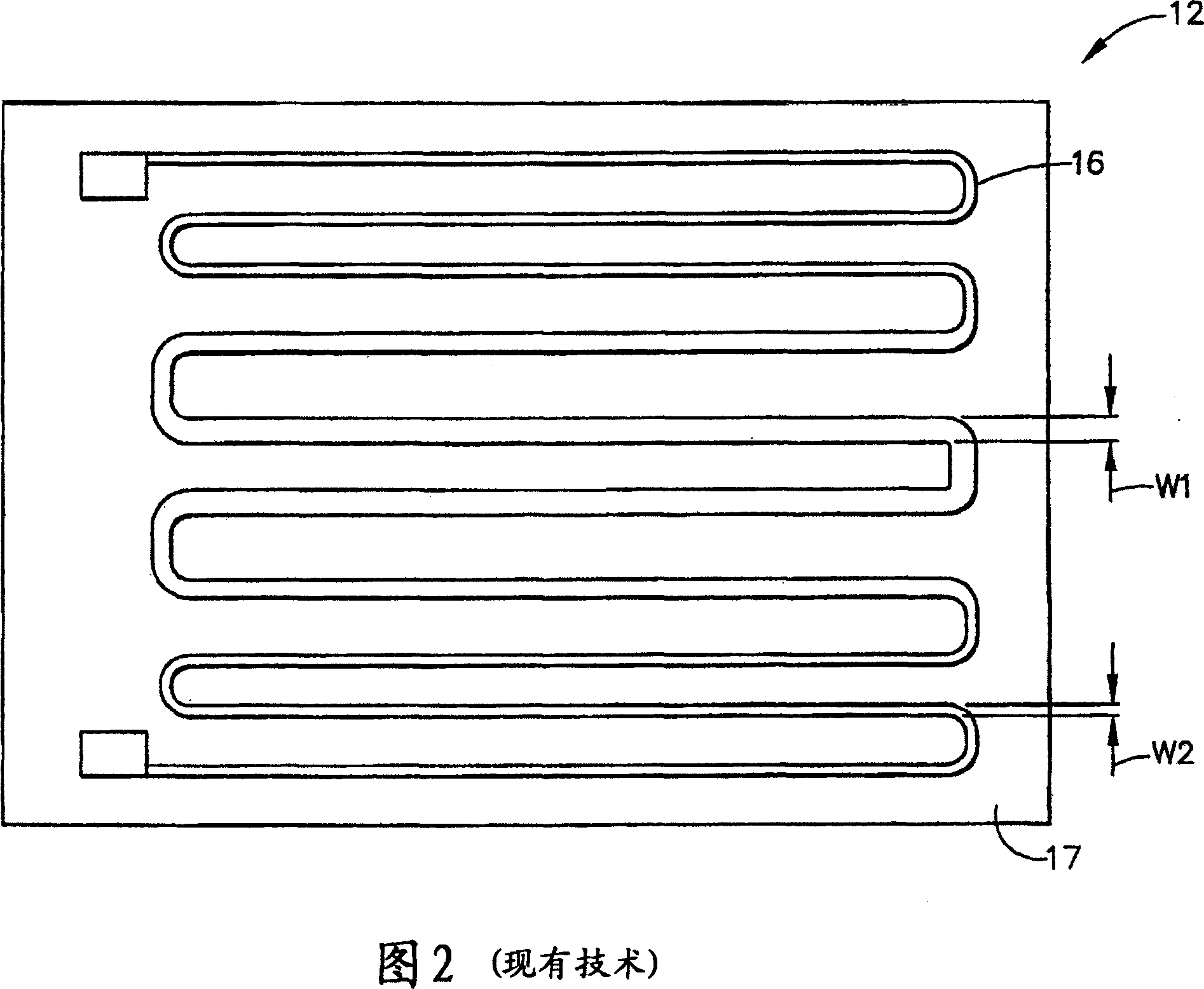

[0037] As further shown in FIG. 2, resistive circuit pattern 16 is formed on a substrate 17 and includes a variable width (eg, W1 and W2) to provide variable power density as d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com