Slide fastener slider with automatic locking device

An automatic locking and zipper technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of not being able to easily assemble sliders, difficult installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

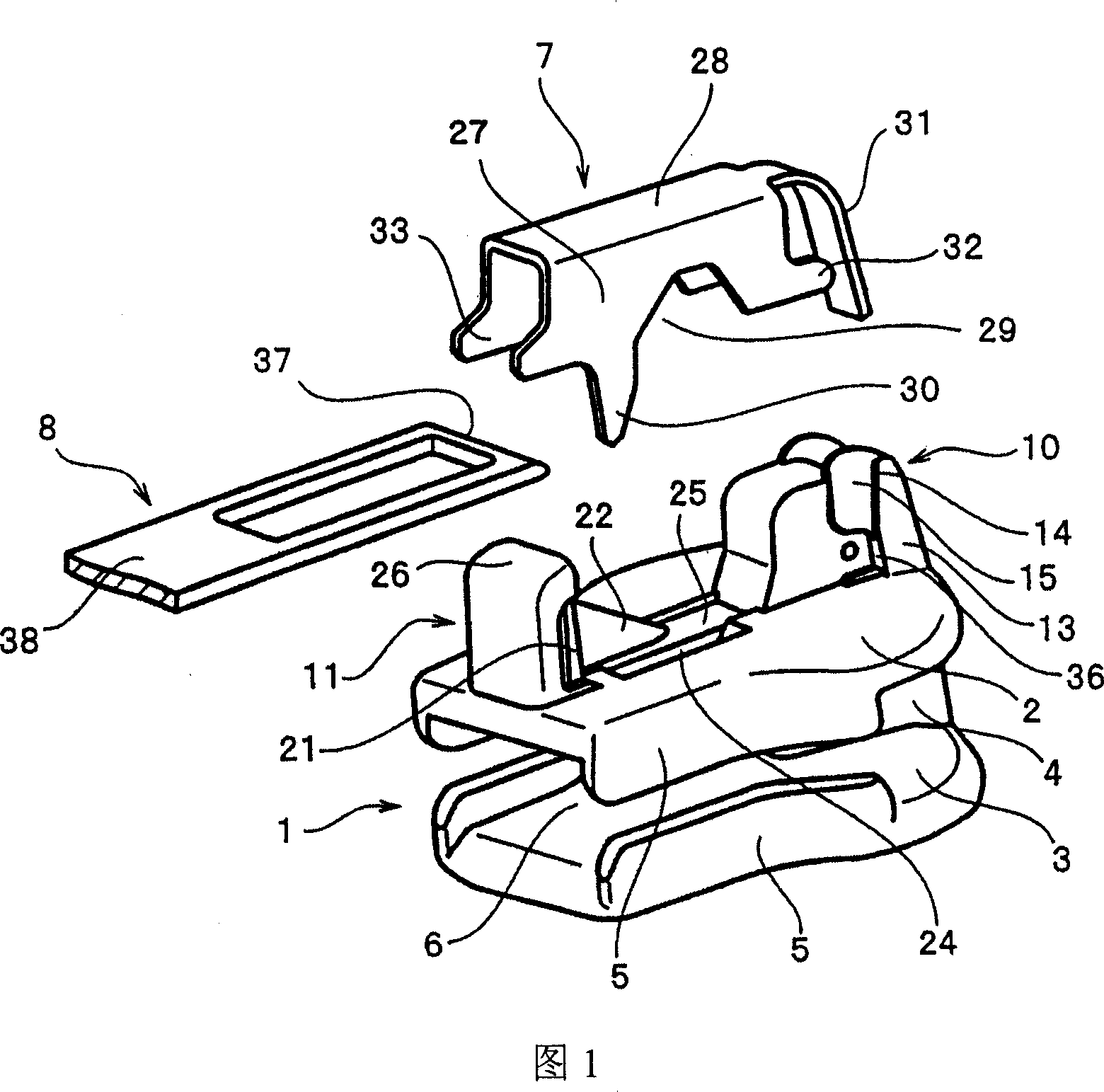

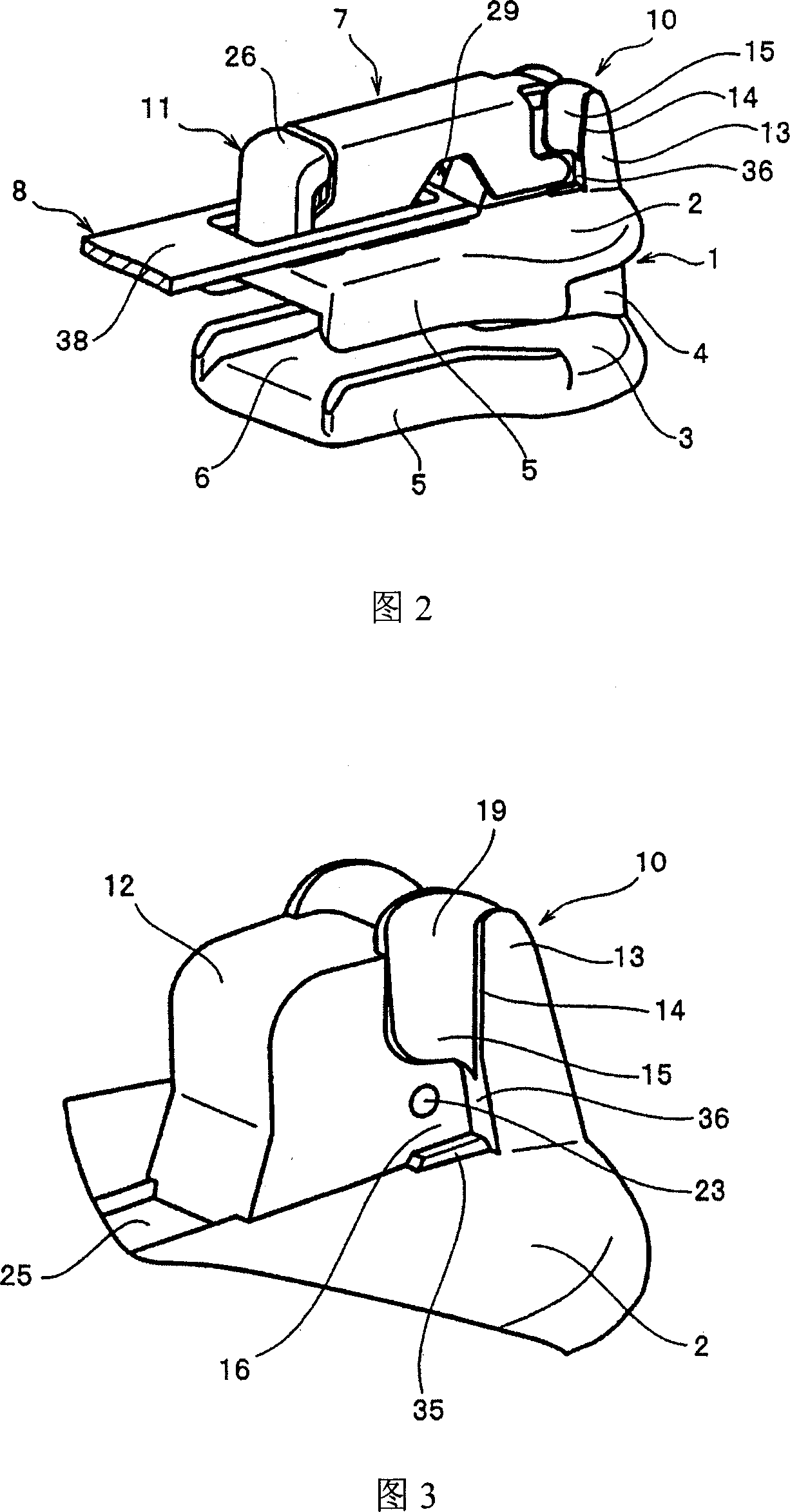

[0045] The sliding zipper slider with automatic locking device according to the first embodiment shown in FIGS. 1 to 7 is preferably configured in such a way that its body 1 is cast by die-casting metal such as zinc alloy or aluminum alloy, and the cover 7 is formed by extruding sheet steel or the like, and tab 8 is cast by die casting metal. The cover 7 may be molded by using a thermoplastic resin such as polyamide, polyacetal, polypropylene or polypropylene terephthalate, and the puller that one prefers to use. A tab can be used as pull tab 8 .

[0046] The slider with automatic stop mechanism is configured by three components: body 1 , cover 7 and pull tab 8 . A locking claw 30 as a locking mechanism is provided on one side surface of the cover 7 so that the locking claw 30 can be inserted between the left and right zipper elements by operating the pull tab 8 . Zipper elements that can be applied to the slider shown in the drawings as an example include zipper elements th...

no. 2 example

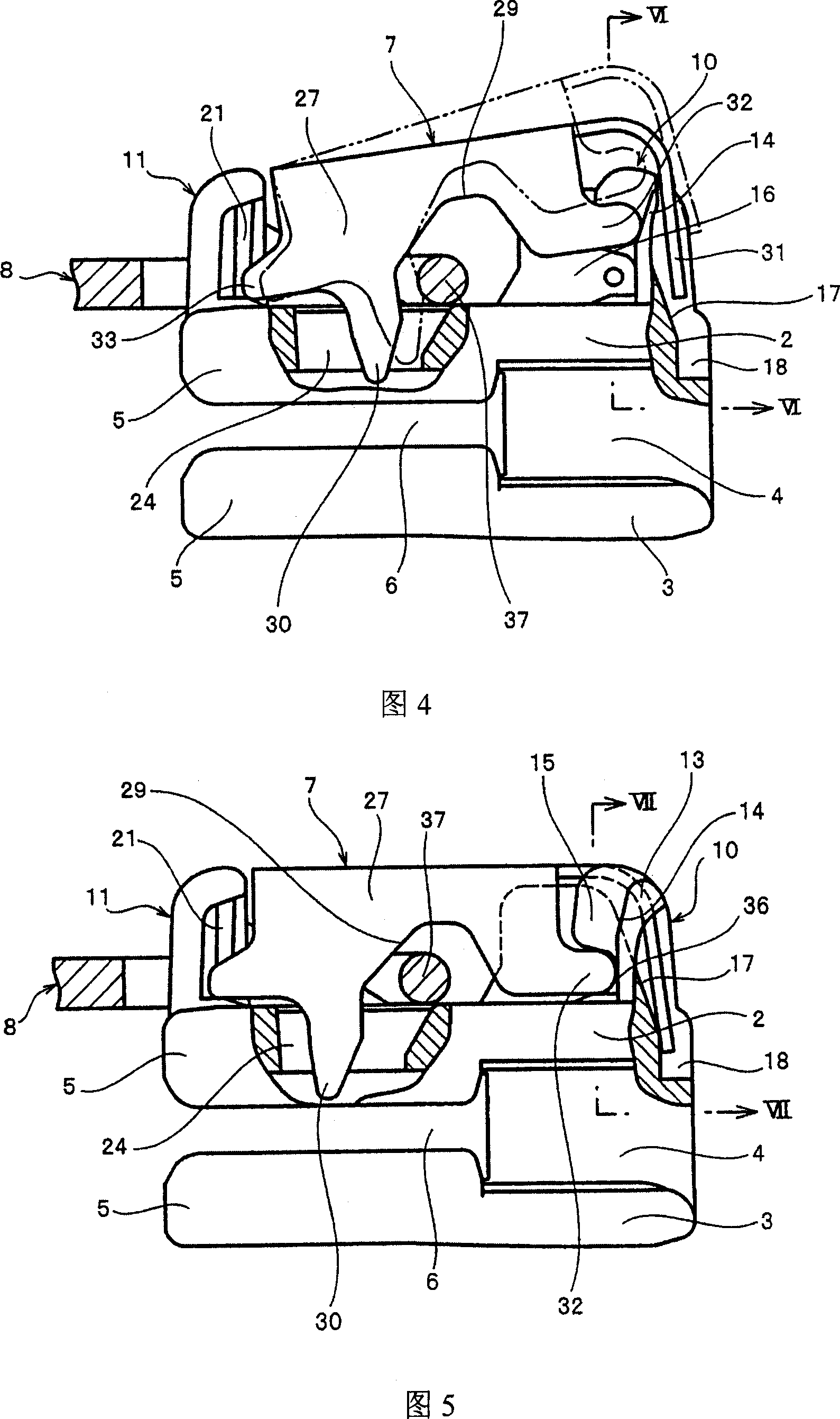

[0057] The sliding zipper slider with an automatic locking device according to the second embodiment shown in FIGS. 9 and 10 has the same structure as that of the first embodiment, except that the supporting part is provided at the front attachment post 10. The structure of the relationship between the expansion portion 13 and the hook piece 15 on each of the two sides of the 12 is different.

[0058] The front attachment post 10 erected on the body 1 has a trapezoidal support portion 12 at its center, and expansion portions 13 are provided on both sides of the support portion 12 so as to protrude from the support portion 12 . The hook piece 15 is protruded from a substantially upper half of the expansion portion 13 to the rear mouth side, and the top side of the hook piece 15 is provided with an inwardly inclined slope 19 . A step is provided on the boundary between the expanded portion 13 and the hook piece 15 so that the guide portion 14 for guiding the front engaged portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com